AGL_Sol_EV3_E_Rev_02 21

Reasons for moving to Speed-Drop Protection mode:

▪ Overtemperature of the power module

▪ Overtemperature in the discharge line

▪ Operating in field weakening range

▪ Output overcurrent

▪ Input overcurrent

▪ Drive ambient temperature foldback

The controller can avoid moving to the Speed-Drop Protection mode by using registers [37], [39],

[40], [41], [42] and [46] for control purposes.

6.2 Power module speed-drop protection

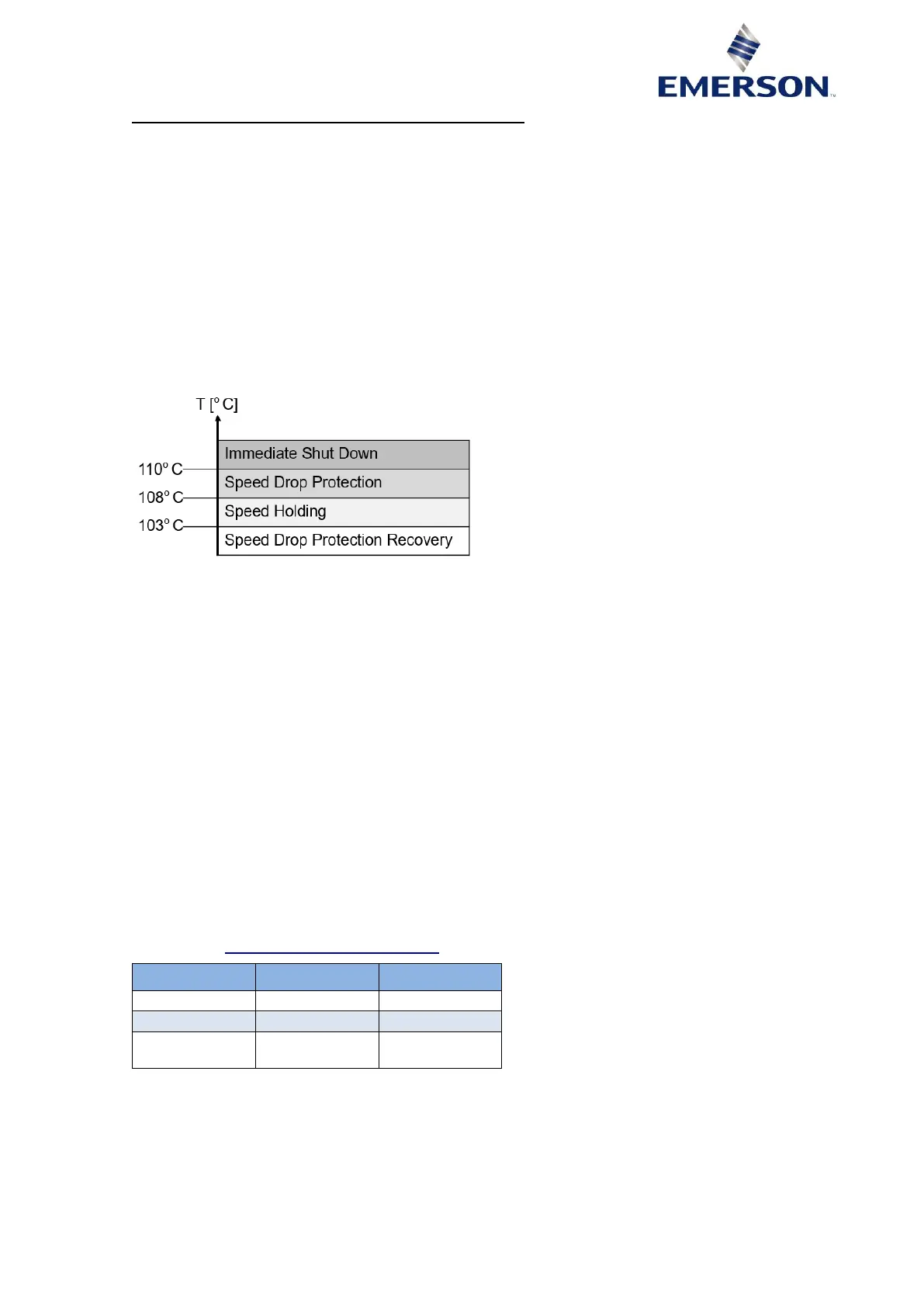

Considering the described speed-drop protection behaviour, the logic for the power module

protection follows the diagram below:

Figure 13: Power module speed drop protection logic

If the temperature reaches 108 °C, the drive will take over the speed demand and will reduce it to

the speed-drop protection speed, in an attempt to reduce the module temperature.

If the speed reaches its speed-drop protection value, and the temperature is still above 108 °C for

30 seconds, the drive will automatically shut down the compressor.

However, if the temperature decreases below 108 °C, the drive will enter in the Speed Holding area,

where the speed is kept constant, until the temperature goes below the recovery value, ie, below

103 °C.

If the temperature goes below the recovery value, the drive will return to the speed commanded

initially.

6.3 Discharge line temperature protection

If a discharge line temperature sensor is wired and activated via register [207] the drive will control

this temperature. This is achieved via the DLT value [77] considering a lower speed-drop protection

limit readable via register [46] or configurable via register [110] and an upper maximum limit [27]. For

YPV* compressors the DLT trip limit ([27]) is configurable through register [222]. The register can be

set within the range of 135 to 150 °C. The configured value will be written in register [27].

Once the drive goes into speed-drop protection mode the functionality is the same as described in

Chapter 6.1 "Speed-Drop Protection mode".

Loading...

Loading...