Type 667 Sizes 80 & 100

2

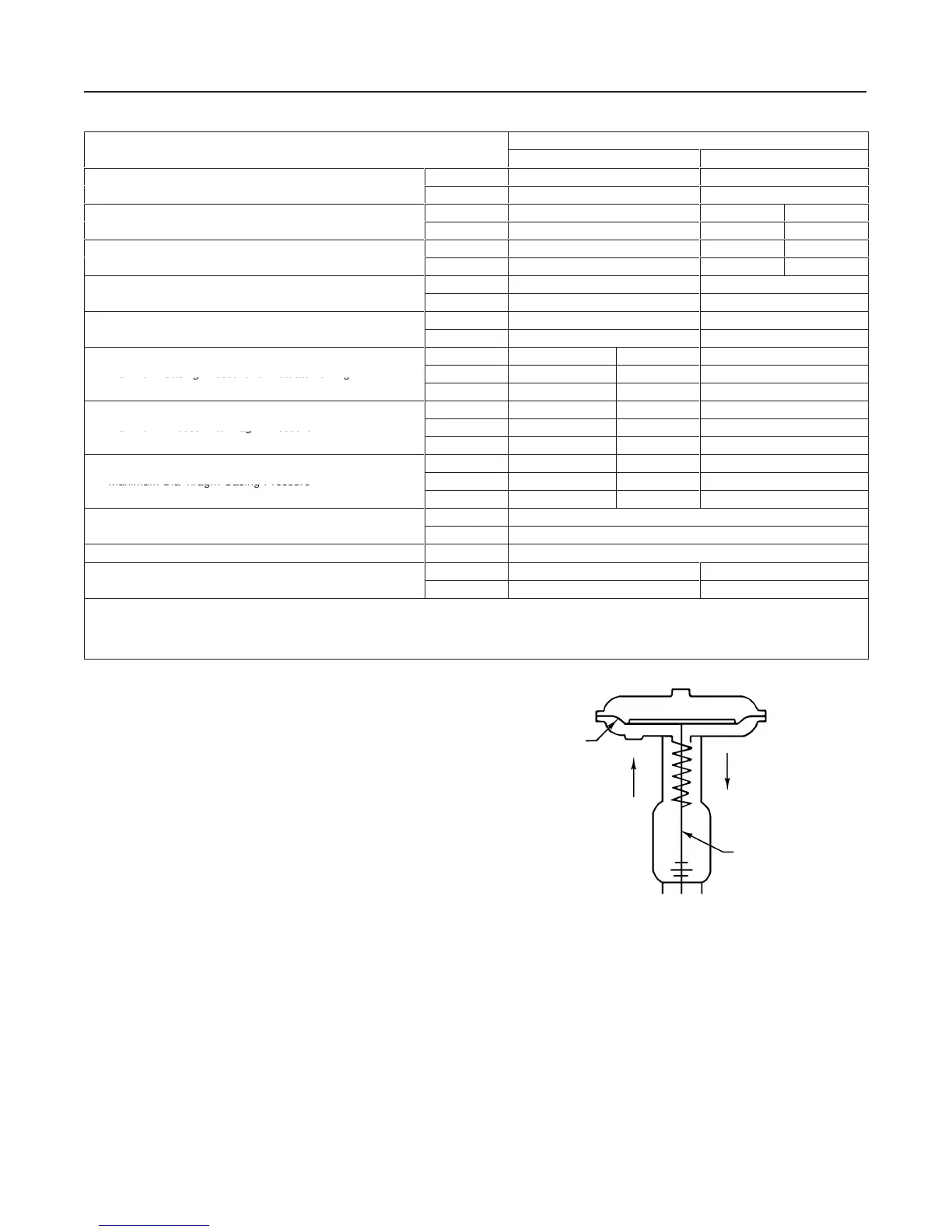

Table 1. Specifications

ACTUATOR SIZE

SPECIFICATION

80 100

p

inch

2

273 450

Nominal Effective Diaphragm Area

cm

2

1761 2902

inch 5 5H

(1)

7

Yoke Boss Diameters

mm 127 127 178

p

table Valve Stem Diameters

inch 1 or 1-1/4 1-1/4 2

Acceptable Valve Stem Diameters

mm 25.4 or 31.8 31.8 50.8

p

lb 14,150

(2)

45,000

Maximum Allowable Output Thrust

N 62,942 200,170

inch 3 4

Maximum Travel

mm 76 102

Cast Iron Steel

Maximum Casing Pressure for Actuator Sizing

(3)

psig 45 70 100

bar 3.1 4.9 6.9

Cast Iron Steel

Maximum Excess Diaphragm Pressure

(4)

psig 20 20 25

bar 1.4 1.4 1.7

Cast Iron Steel

Maximum Diaphragm Casing Pressure

(5)(6)

psig 60 80 115

bar 4.1 5.5 7.9

p

p

_F

–40 to 180

Material Temperature Capabilities

_C

–40 to 82

Pressure Connections 1/4 inch NPT female

pp

roximate Weights Without Handwheel

lb 626 1200

Approximate Weights Without Handwheel

kg 284 544

1. Heavy actuator-to-bonnet bolting.

2. 19,800 lb (88,075 N) for steel construction.

3. Maximum diaphragm casing pressure that can be applied to cause travel stop contact. Indicated pressure must not be exceeded at less than full travel.

4. Maximum additional diaphragm casing pressure that can be applied after the travel stop cap screw contacts the upper diaphragm casing.

5. The sum of the pressure required to stroke the valve fully and the excess pressure added when the actuator is against the stop must not exceed these values.

6. This maximum casing pressure is not to be used for normal operating pressure. Its purpose is to allow for typical regulator supply settings and/or relief valve tolerances.

Description

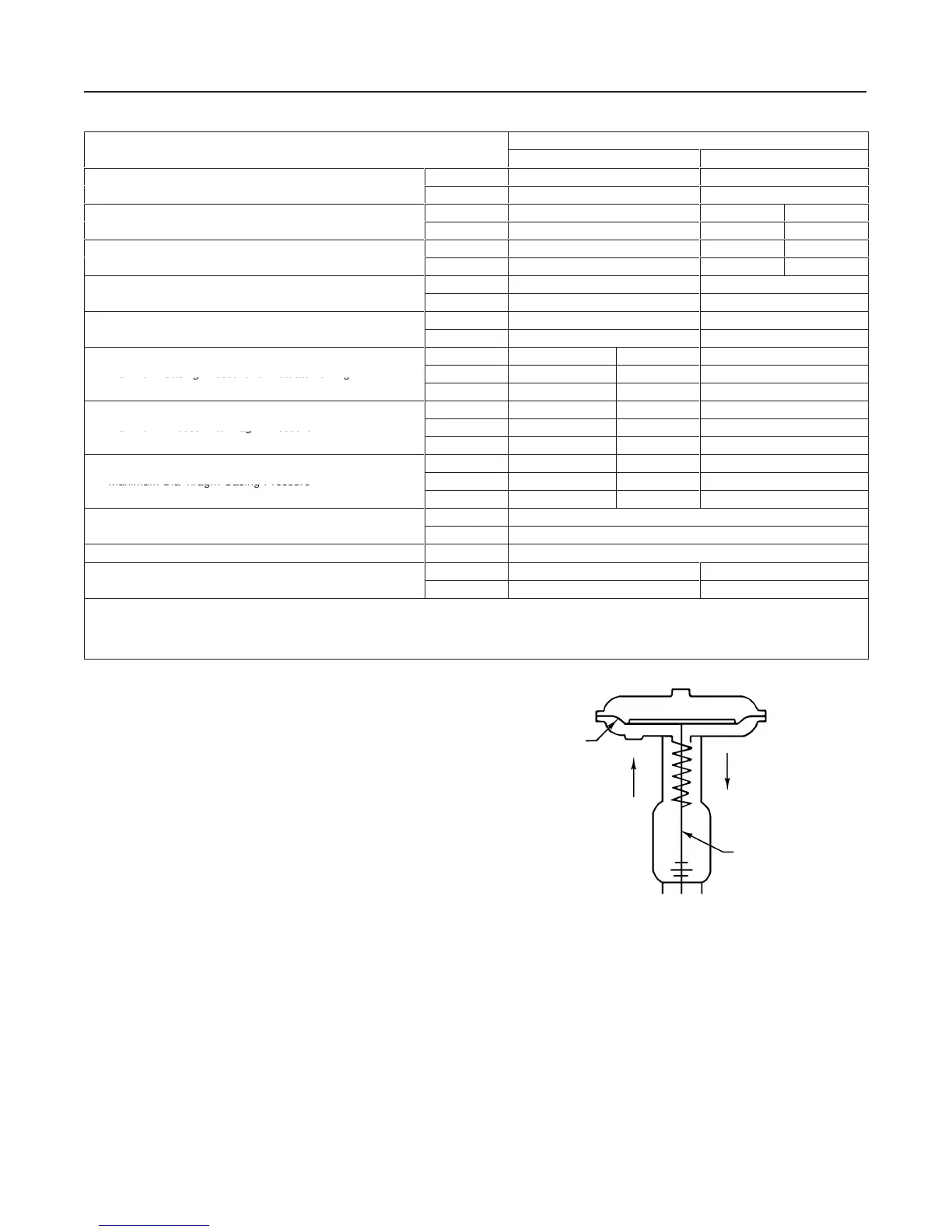

The Type 667 actuator is a reverse-acting actuator.

Reverse-acting actuators use air action to lift the dia-

phragm (away from the valve), and spring action op-

poses the diaphragm action (see figure 2). The actua-

tor position changes in response to varying controlled

air pressure to the diaphragm. If air pressure is re-

duced or lost from the actuator diaphragm, spring ac-

tion will extend the actuator stem. The actuator is

often used with control valves using a pneumatic posi-

tioner for air pressure control, and where fail action will

fully open or close the control valve as the actuator

stem extends.

Also, the actuator can be furnished with either a side-

mounted (size 80 only) handwheel assembly or a top-

mounted handwheel (size 100 only). The size 80 side-

mounted handwheel is normally used as an auxiliary

manual actuator. The size 100 top-mounted hand-

wheel is used as either a travel stop or an auxiliary

manual actuator.

The actuator can be furnished with a top-loading capa-

bility. A top-loaded actuator allows air pressure to be

applied to the top of the diaphragm, aiding the spring

Figure 2. Schematic Representation of Type 667 Actuator

DIAPHRAGM

AIR

LIFTS

SPRING

PUSHES

DOWN

ACTUATOR

STEM

AF3833-A

A6127 / IL

to extend the actuator stem. This air pressure in-

creases valve seat load on valve applications where

additional seat-loading is necessary.

Specifications

Refer to table 1 for Specifications of the Type 667 ac-

tuator. See the actuator nameplate for information

about a specific actuator.

Loading...

Loading...