The Calibration Screen General Operation of RLDS - UI • 39

IMPORTANT: Changing information on CAL

FACTOR will VOID the factory calibration.

Typically, the unit will remain within the

factory-calibrated accuracy indefinitely and no

calibration is required. Complex software algorithms

adjust for temperature drift, IR source aging, and

pressure changes in order to keep the unit within

factory accuracy specifications.

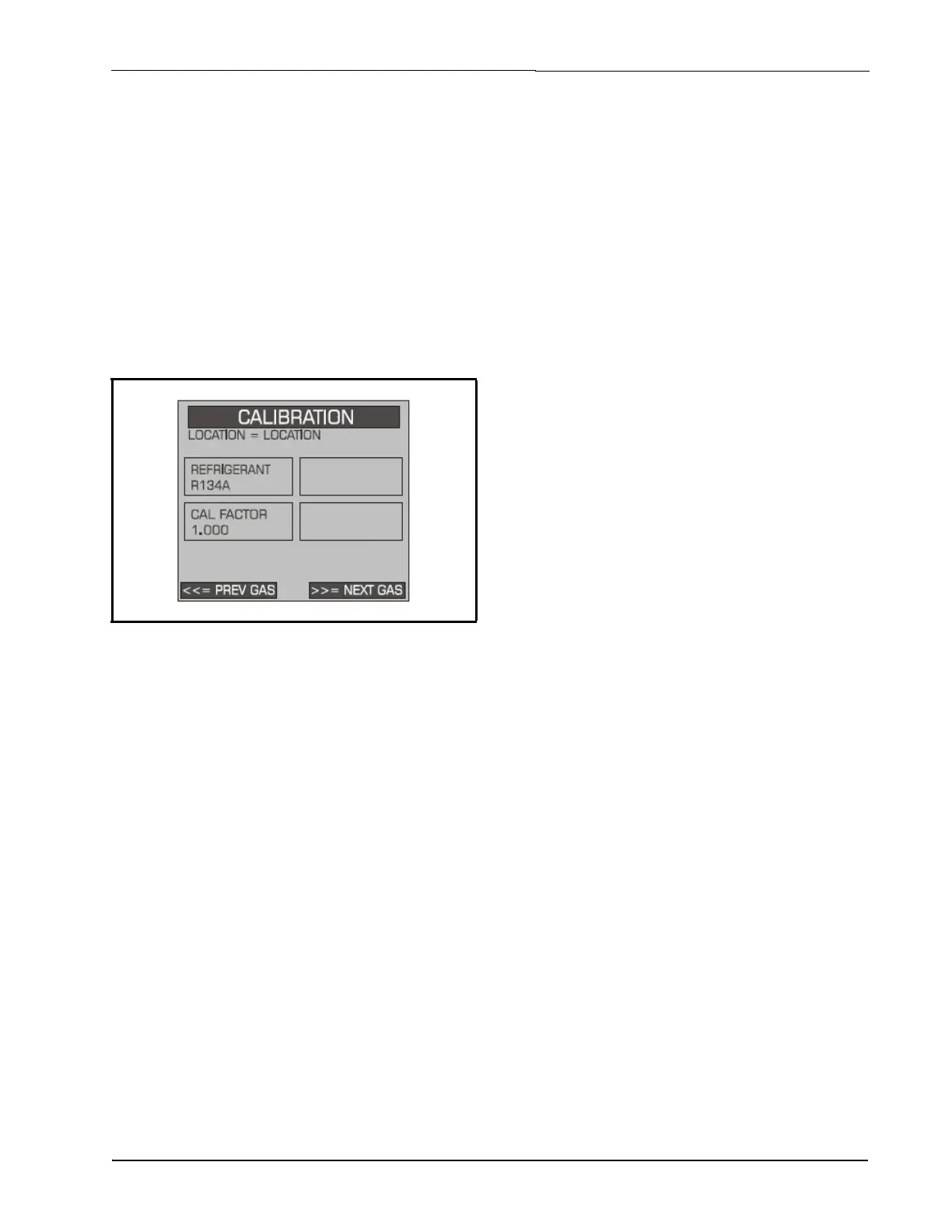

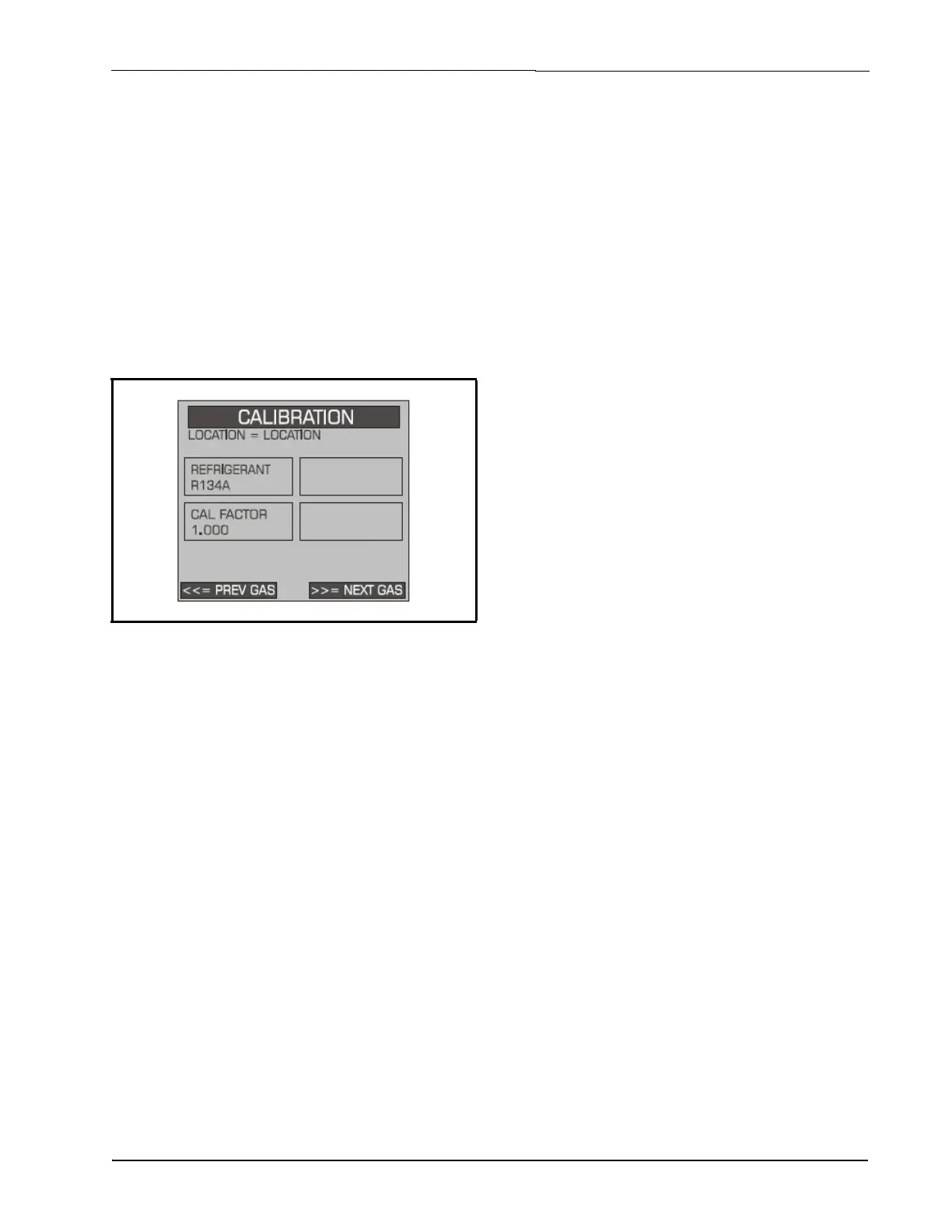

8.9.2. Navigating to the Calibration

Screen

On the System Setup screen (Figure 7-3), select the

Calibration option abbreviated CAL.

8.9.3. Adjusting Calibration Factor

The factory default CAL factor for standard units is

1.000. This value may be different if the high

accuracy option is ordered. Proceed as follows to

adjust the current calibration factor:

1. Use the PREV GAS or NEXT GAS options to

scroll through the list of refrigerants until the

gas you wish to work with is displayed.

2. Select the CAL FACTOR option to edit the

value.

3. Use the left/right cursor keys to move across

the entry field and the up/down cursor keys to

modify the individual numbers.

4. Press ENTER to accept the new entry or ESC

to revert to the previous setting.

8.9.4. CO

2

Atmospheric

Concentration

(RLDS-CO

2

Units Only)

CO

2

is supported by RLDS-CO

2

units. Because CO

2

is present in ambient air, a relative reading is used to

determine the amount of CO

2

coming from a leak.

The CAL screen offers the ability to enter the

atmospheric CO

2

concentration manually. This value

is typically in a range of 380-400 PPM depending on

location. Enter the CO

2

concentration as follows:

1. After selecting CO

2

as the desired gas and

setting the CAL FACTOR, you will be

prompted to enter the CO

2

concentration value.

2. Use the up/down cursor keys to modify the

numbers to set to the appropriate value.

3. Press ENTER to accept the new entry or ESC

to revert to the previous setting.

8.9.5. Calibration Procedure

The CAL FACTOR is determined by sampling a

known dilution of the type of refrigerant gas to be

sampled. The sample must be prepared to less than

half the desired accuracy, and the concentration must

be corrected for ambient temperature and pressure at

the time of measurement.

Calibration is best performed at or near full scale

(1,000 PPM). It can, however, be done at any

concentration, and ideally in the range where

maximum accuracy is desired down to, but not below

100 PPM.

A cylinder of refrigerant gas at a certified PPM level

must be used to ensure that sampling occurs at

ambient conditions. A minimum sample size of 5

liters is required.

The RLDS should be operating for at least one hour

prior to performing a calibration.

Prepare the RLDS for sampling by initially setting its

CAL FACTOR to 1.000. Next, set up the RLDS for a

logging interval of zero minutes (Section 8.2.6., Log

Interval), and place the RLDS in its zone hold mode

for the zone you wish to use for calibration purposes

(Section 7.10., Zone Hold Time).

Connect the sample bag directly to the intake port for

the zone you have set up and allow the RLDS to

sample the entire bag. When sampling is complete,

view the trend data for the zone used to sample

(Section 8.8., The Trend Screen). Read the measured

Figure 8-10 - Calibration Screen

Loading...

Loading...