Europe, Middle East, and Africa Only

(1)

See Nameplate

1. The pressure/temperature limits indicated in this instruction manual or any

applicable standard or code limitation should not be exceeded.

2. At average ambient temperature.

Functional Features

Accuracy Class AC : Up to ± 1%

Lockup Pressure Class SG : Up to + 5%

Class of Lockup Pressure Zone SZ : Up to 5%

Accuracy Class AG : ± 1%

Response Time t

a

: ≤ 1 second

Temperature

Standard Version: Working -10° to 60°C

Low Temperature Version: Working -20° to 60°C

Materials

Flanges and covers: Steel

Diaphragms: Fabric Nitrile (NBR)+PVC/

Nitrile (NBR) rubber

Pads: Nitrile (NBR) rubber

LABELLING

Note 1: See “”

Note 2: Year of manufacture

Note 3: Class 1: -10°/60°C

Class 2: -20°/60°C

Note 4: PN 16 PS: 16 bar

PN 25 PS: 25 bar

ANSI 150 PS: 19,3 bar

ANSI 300 PS: 50 bar

ANSI 600 PS: 100 bar

OVERPRESSURE PROTECTION

The recommended safety pressure limitations are stamped on

the regulator nameplate. If actual version hasn’t a built-in safety

shut-off device, some type of overpressure protection is needed

if the actual inlet pressure exceeds PS (see nameplate).

Downstream side pressure after safety shut-off device’s

intervention (in the built-in safety shut-off device

congurations) shall stay within the actual maximum

operating set-up range to avoid anomalous back pressures

that can damage the safety shut-off device’s pilot.

Equipment’s operation below the maximum pressure

limitations does not preclude the possibility of damage from

external sources or debris in the line.

Downstream overpressure protection shall be also provided

if the safety shut-off device outlet pressure can be greater

than the PS of the safety shut-off device pilot (differential

strength type). The regulators and possible built-in safety

shut-off device should be inspected for damage after any

overpressure condition and intervention.

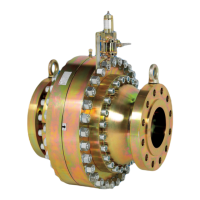

TRANSPORT AND HANDLING

Established transport and handling procedures shall be

followed to avoid any damage on the pressure containing

parts by shocks or anomalous stresses.

Ringbolts are designed just for handling of equipment weight.

Built-up sensing lines and pressure accessories (e.g. pilots)

shall to be protected by shocks or anomalous stresses.

APPARECCHIO TIPO /DEVICE TYPE

Wau

DN2

DN1

MATRICOLA

bar

bar

SERIALNr.

°C

FLUIDO GRUPPO

FLUIDGROUP

ANNO

YEAR

HARMONIZEDSTD.

bar

NORMEARMONIZ.

LEAKAGECLASS

CLASSEDI PERDITA

FUNCTIONALCLASS

CLASSEFUNZIONALE

bar

Wao

Wa

TS

bar

pao

Cg

PS

body

bar PT= xPS bar

PS

covers

EN

bar

pmax

xxxx

body

Notified

BOLOGNAITA LY

O.M.T.

1.5Note 4Note 3

Note 2

Note 1

1

-

Figure 2. Label for FL Series Regulators

Loading...

Loading...