Europe, Middle East, and Africa Only

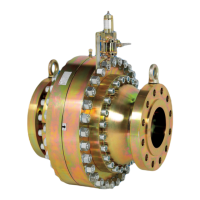

Figure 3. FL Series Configurations

Table 2. FL Series Configurations

FL REGULATOR BFL REGULATOR + SLAM-SHUTMFL REGULATOR + MONITOR

CONFIGURATIONS

ID-ABBREVIATIONS

Standard

Silenced

Standard

Silenced

SR SRS SR SRII SRS SRSII

Regulator FL-BP FL-BP-SR FL-BP-SRS FL FL-SR FL-SRII FL-SRS FL-SRSII

Regulator + Monitor MFL-BP MFL-BP-SR MFL-BP-SRS MFL MFL-SR MFL-SRII MFL-SRS MFL-SRSII

Regulator + Slam-shut BFL-BP BFL-BP-SR BFL-BP-SRS BFL BFL-SR BFL-SRII BFL-SRS BFL-SRSII

Note : Types SRII and SRSII are not available for DN 40 and DN 65 sizes. Size DN 200 is available only with SRII or SRSII. SRS/SRSII silenced solutions have a

widened output ange. Also available: SRS-R reinforced version; version with widened output but without a built-in silencer.

ATEX REQUIREMENTS

If the provisions of EN 12186 and EN 12279,

national regulations, if any, and specic manufacturer

recommendations are not put into practice before

installation and if purge by inert gas is not carried out before

equipment’s start-up and shut-down operations, a potential

external and internal explosive atmosphere can be present

in equipment and gas pressure regulating/measuring

stations/installations.

If a presence of foreign material in the pipelines is foreseen

and purge by inert gas is not carried out, the following

procedure is recommended to avoid any possible external

ignition source inside the equipment due to mechanical

generated sparks :

drainage to safe area via drain lines of foreign materials, if •

any, by inow of fuel gas with low velocity in the pipe-work

(5m/sec)

In any case,

provisions of Directive 1999/92/EC and 89/655/EC shall •

be enforced by gas pressure regulating/measuring station/

installation’s end user

with a view to preventing and providing protection against •

explosions, technical and/or organisational measures

appropriate to the nature of the operation shall be taken

(e.g. : lling/exhausting of fuel gas of internal volume

of the isolated part/entire installation with vent lines to

safe area - 7.5.2 of EN 12186 and 7.4 of EN 12279 ;

monitoring of settings with further exhaust of fuel gas to

safe area ; connection of isolated part/entire installation to

downstream pipeline; ….)

provision in 9.3 of EN 12186 and 12279 shall be enforced by •

pressure regulating/measuring station/installation’s end user

external tightness test shall be carried out after each •

reassembly at installation site using testing pressure in

accordance with national rules

periodical check/maintenance for surveillance shall be •

carried out complying with national regulations, if any, and

specic manufacturer recommendations.

DESCRIPTION

The FL Series regulators are used in reduction, distribution and conveying stations using suitably ltered natural gas.

They can also be used for air, propane, butane, LPG, city gas, nitrogen, carbon dioxide and hydrogen.

Loading...

Loading...