Do you have a question about the Emerson Topworx D Series and is the answer not in the manual?

Explains the two primary operating modes and their corresponding valve positions and indicator directions.

Provides guidance and considerations for physically attaching the TopWorx unit to a valve.

Outlines recommended conditions for storing the unit before installation to maintain integrity.

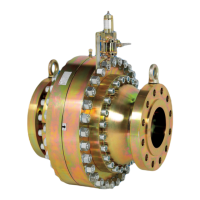

The TopWorx D-Series with AS-interface is a device designed for controlling and monitoring process valves, offering robust functionality for industrial applications. This manual provides comprehensive instructions for its installation, operation, and maintenance, ensuring reliable performance and longevity.

The D-Series unit acts as a discrete valve controller, integrating position sensing and pneumatic control into a single, compact assembly. Its primary function is to provide feedback on valve position (open/closed) and to actuate the valve through an integrated spool valve. The AS-interface (Actuator Sensor Interface) communication protocol allows for simplified wiring and seamless integration into control systems, reducing installation time and complexity.

The device is capable of both "normal acting" and "reverse acting" operations. In a "normal acting" configuration, the indicator dome rotates clockwise (CW) when the process valve is closed and counter-clockwise (CCW) when the process valve is open. Conversely, in a "reverse acting" setup, the indicator dome rotates CW when the process valve is open and CCW when the process valve is closed. This flexibility ensures compatibility with various valve types and process requirements.

The core of the D-Series functionality lies in its ability to detect valve position using internal limit switches and to control pneumatic actuators via an integrated spool valve. The SCM-ASI (Sensor Communication Module - AS-interface) is central to this, handling communication with the AS-i network and managing the input/output signals. It provides feedback on the valve's open and closed states and controls the solenoid valve(s) responsible for pneumatic actuation.

For pneumatic control, the D-Series utilizes a 5-port, 4-way spool valve driven by an internally mounted pilot valve. This design allows for precise control of double-acting or spring-return actuators. The spool valve's supply and work ports are clearly marked for correct pneumatic hookup. The device is designed to operate with dried, filtered air, ensuring clean and efficient pneumatic operation.

The D-Series is designed for ease of installation and versatile mounting options. It can be mounted directly on a quarter-turn valve using various mounting bracket kits, which are available to suit specific application needs, whether rotary or linear. The indicator dome assemblies are highly adaptable, accommodating a wide range of mounting arrangements and can be adjusted up to 9° off-axis if required. For 45° indicator dome assemblies, normal acting applications mounted parallel ±9° are supported.

The unit ships with temporary covers for conduit entries and spool valve port connections to protect internal components from debris during shipment and handling. It is crucial for installers to replace these with appropriate permanent sealing devices to maintain the specified IP/NEMA rating, especially when stored outdoors or installed in harsh environments.

The AS-interface communication module simplifies wiring significantly. It allows for the connection of AS-i communication wires directly to the designated terminals, enabling the AS-i network to have full control of the valve once the SCM-ASI has been addressed. The module also supports external switch inputs for auxiliary limit switches, providing additional flexibility for monitoring.

The device includes an indicator dome that visually represents the valve's position. These domes are made of polycarbonate and are UV F1 rated, ensuring durability and clear visibility. They are available in various color-coded options and rotations (90°, 180°, and Thru-divert) to suit different valve types and visual preferences.

For pneumatic connections, the manual emphasizes the importance of sound mechanical practices. It recommends flushing the system to remove debris before connecting the supply air to the spool valve and using a 40-micron point-of-use filter at every device to prevent contamination. The spool valve itself is designed for reliable operation with specific pressure and flow coefficient ratings.

The D-Series also offers optional features such as manual overrides for the spool valve, including latching/non-latching push-type and palm actuator types, providing a means of local valve control independent of the AS-i network. Different valve body materials (hardcoat anodized aluminum, 304, or 316 stainless steel) and seal materials (Buna-N, Silicone) are available to match various application requirements.

The D-Series is engineered for long-term reliability with minimal maintenance. TopWorx states that the Discrete Valve Controllers are designed to operate for one million cycles without servicing, highlighting their robust construction and durable components. Preventative maintenance kits and instructions are available upon request when approaching this operational milestone.

Calibration of the limit switches within the SCM-ASi module is a straightforward process, although it should never be performed in hazardous areas. The procedure involves using the on-board calibration switch to cycle the valve and adjust the cams until the corresponding LED indicators (Red for closed, Green for open) light up. This ensures accurate position feedback.

For pneumatic connections, the manual provides specific recommendations to prevent issues. It strongly advises against using hard-setting pipe compounds and recommends Locktite 567 brand thread sealant. If Teflon tape is used, it should be wrapped starting from the second thread to prevent tape shreds from contaminating the spool valve seals.

Installation of breathers (AL-M31) in the exhaust ports is recommended to prevent debris from falling into the spool valve and damaging the seals. This is a critical step for maintaining the integrity of the pneumatic system, especially prior to installation or storage.

The manual also includes warnings regarding the use of flow controls. While a flow control may be used in Port 3, it should never be used in Port 5, as any blockage or restriction in Port 5 can cause an internal pressure build-up inside the enclosure, posing a safety risk.

The device's construction materials, such as cast A360 aluminum with dichromate conversion coating and epoxy-coated exterior, or cast 316 stainless steel, contribute to its durability and resistance to harsh environments, reducing the need for frequent maintenance. Fasteners are typically 304 stainless steel, with 316 stainless steel as an optional upgrade, further enhancing corrosion resistance.

The design allows for easy access to internal components for maintenance or replacement if needed. For instance, the enclosure lid can be removed, and the shaft can be disengaged from the ID bushing, provided sufficient clearance is available. The modular design of components like spool valves and pilot devices facilitates replacement if necessary, with various replacement assemblies listed in the manual.

Overall, the D-Series is designed to be a low-maintenance, high-reliability device, with clear instructions and recommendations to ensure its optimal performance throughout its operational life.

| Category | Controller |

|---|---|

| Operating Temperature | -40°C to 85°C |

| Output Signal | 4-20 mA |

| Enclosure Rating | NEMA 4X |

| Pressure Range | Not Applicable |

| Housing Material | Aluminum |

| Ingress Protection | IP66 |

| Certifications | ATEX, IECEx |

| Communication Protocol | HART, Foundation Fieldbus, AS-Interface |

| Number of Outputs | 2 |

| Number of Inputs | Varies depending on model (typically 2) |

Loading...

Loading...