CPY7B Maintenance

Endress+Hauser 11

6 Maintenance

Routine checks

Regularly check all couplings for leaks

‣

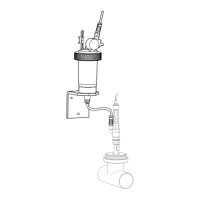

Version CPY7B-A

Visual inspection

Version CPY7B-B, CPY7B-C

1. Cut off the compressed air supply using the manually operated valve (toggle to

horizontal position).

2. Observe the pressure gauge on the CPY7B. If the pressure has not dropped after 15

minutes, the couplings are leak-tight.

3. If the pressure has dropped, re-tighten the couplings. Check the seal to ensure it is

intact and seated correctly.

NOTICE

Prohibited lubricants

If prohibited lubricants are used, there is a risk of stress cracks forming on the polycarbonate

parts.

‣

Use only the lubricants approved for the material to lubricate polycarbonate parts, such as

couplings.

‣

Observe the instructions of the lubricant manufacturer.

Release vessel pressure (only versions CPY7B-B, CPY7B-C)

L

CAUTION

Minor skin or eye injuries are possible as a result of splashing electrolyte

‣

Only ever perform other maintenance work when the system is unpressurized.

‣

If using an air pump connection:

Release the valve nipple on the cover by one rotation (AF 19).

If using a compressed air connection:

1. Cut off the compressed air supply at the manually operated valve (toggle bar in

horizontal position).

2. Remove the compressed air hose (turn hose union 1 revolution counterclockwise).

3. Release the pressure from the vessel (toggle bar of manually operated valve in vertical

position).

Loading...

Loading...