Installation CPY7B

6 Endress+Hauser

3.3 Scope of delivery

• 1 electrolyte vessel

• 1 spacer tube

• 3 m (9.8 ft) PTFE pressure hose 4/6

• 1 open-ended wrench, hybrid, SW17/19

• 1 Operating Instructions BA00128C

• Additionally, depending on the version:

– 1 fixing bracket (CPY7B-A0, CPY7B-B0, CPY7B-C0)

– 1 threaded joint Pg 9 (CPY7B-A0, CPY7B-B0, CPY7B-C0)

– 2 hose couplings with check valve (CPY7B-B0, CPY7B-C1, CPY7B-C0, CPY7B-C1)

– 1 air pump connection (CPY7B-B0, CPY7B-C1, CPY7B-C0, CPY7B-C1)

– 0.5 m (1.7 ft) spiral pressure hose (PA12W) (CPY7B-B1, CPY7B-C1)

– 1 hose connector (CPY7B-B1, CPY7B-C1)

If you have any questions, please contact your supplier or your local sales center.

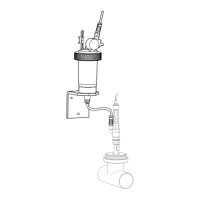

4 Installation

4.1 Installation conditions

Instructions for installing in pressurized systems

General

‣

Only the pressure-resistant versions – CPY7B-B or CPY7B-C – should be operated in

pressurized systems.

‣

Never exceed the maximum permitted pressure of 11 bar (160 psi) at an ambient

temperature of 30 °C (86 °F).

‣

Only use the pressure hose supplied.

‣

Regularly check the couplings, valves and hoses for leaks and damage.

Before installing or removing the electrolyte vessel or filling the vessel:

‣

Ensure the system is unpressurized and vent the vessel where necessary.

In the event of severely fluctuating medium pressure:

‣

Regulate the pressure in the electrolyte vessel in such a way that it is always above the

medium pressure.

Loading...

Loading...