Oxymax COS22 Installation

Endress+Hauser 11

For a complete installation of a measuring point, proceed as follows:

1. Install a retractable or a flow assembly (if used) into the process.

2. Connect the water supply to the rinse connections (if you use an assembly with

cleaning function).

3. Install and connect the oxygen sensor.

NOTICE

Installation error

Cable open circuit, loss of sensor due to cable separation, unscrewing of membrane cap

‣

Do not install the sensor suspended from the cable.

‣

Screw the sensor into the assembly so that the cable is not twisted.

‣

When installing or uninstalling the sensor body, hold it tightly. Turn using only the

hexagonal nut on the armored coupling. Otherwise you might unscrew the membrane

cap. This will then remain in the assembly or process.

‣

Avoid exerting excessive tensile force on the cable (e.g. from jerky pulling).

‣

Select an installation location that is easy to access for later calibrations.

5.3 Installation examples

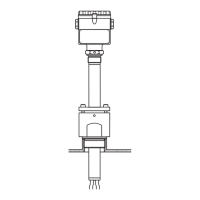

5.3.1 Permanent installation (CPA442)

The permanent installation assembly CPA442 enables easy adaptation of a sensor to

nearly any process connections from Ingold nozzles to Varivent or Tri-Clamp connections.

This kind of installation is very well suited for tanks and larger pipes. You will achieve a

defined immersion depth of the sensor into the medium in the simplest way.

5.3.2 Flow assembly

CPA240

The flow assembly CPA240 offers up to three installation spaces for sensors with a shaft

diameter of 12 mm (0.47"), a shaft length of 120 mm (4.7"), and a Pg 13.5 process

connection. It very well suited for use in pipelines or hose connections. To prevent

Loading...

Loading...