Do you have a question about the Endress+Hauser Prosonic FMU 860 and is the answer not in the manual?

| Brand | Endress+Hauser |

|---|---|

| Model | Prosonic FMU 860 |

| Category | Measuring Instruments |

| Language | English |

Water level measurement, e.g. for controlling water inflow and outflow, or for pump control.

Flow rate measurement in flumes or weirs to determine water level with millimeter accuracy.

Two-channel unit for differential level measurement, e.g. for controlling the screen cleaning process.

An ultrasonic pulse is emitted and reflected by the surface. Height is calculated from the echo signal's run time.

The keypad configures the transmitter and displays parameters on a 4 1/2 character display.

Minimizes start-up time using preset parameters, automatically setting the measuring line for typical applications.

Details on level measurement characteristic curves and flow rate measurement Q/h characteristic curves.

Operating the transmitter via serial interface with a handheld terminal for easier input and information access.

Ensuring minimum resistance in the circuit for correct transmission of the communications signal.

Connecting intrinsically safe Smart transmitters to a PC via Commubox FXA for remote operation.

Hardware and software for connecting to PCs and Rackbus systems via RS-485 interface.

Linking the Prosonic FMU 86... to existing process control systems via the RS-485 interface.

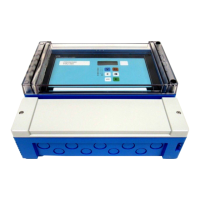

The transmitter electronics are built into an IP 66 housing for wall or post mounting.

Operating unit separated from transmitter electronics, for control cabinet or assembly rack mounting.

For certified systems, sensor in hazardous area, transmitter in safe area. Observe local regulations.

Accessories for mounting and protecting the IP 66 housing, available in aluminum or stainless steel.

Accessories for mounting the transmitter on posts, available in galvanized steel or stainless steel.

Handheld terminal for Prosonic with integrated serial interface and INTENSOR protocol.

Handheld terminal with integrated serial interface for HART protocol.

Converter for connecting a PC to the RS-485 interface for bus communication.

Interface card for connecting a PC to the RS-485 interface for bus communication.

Connection cables for Prosonic FMU 86... transmitters to various FDU sensors.

Overvoltage protection unit for power supply in the IP 66 protective housing.

Power supply unit for sensor heating with integrated overvoltage protection.

Details on alternating and direct voltage inputs, power consumption, and ripple with smart transmitters.

Terminal strip for cable diameters up to 2.5 mm², with prestamped cable entries.

Connection via supplied or extension cable, specifying maximum values for resistance and capacitance.

Current output, relay outputs, power connection and sensor inputs are electrically isolated.

Connecting a separate keypad to the transmitter electronics via a cable.

Diagram showing terminal connections for FMU 860/861/862, including isolated areas.

Diagram of a modified terminal strip for RS-485, specifically for the version with three relays.

Connecting up to 20 devices over a synchronizing connection for parallel sensor lines over long distances.

Manufacturer, instrument, technical documentation, version, and core application data.

Specifies non-contact, continuous level measurement, flow determination, and pump control applications.

Details measuring principle (ultrasonic echo) and modularity for FMU 860, 861, and 862.

Specifies measured variable (time of flight) and measuring range based on ultrasonic sensors.

Details output signals (4-20 mA, 0-20 mA), error signals, current limit, integration time, and load.

Information on relay version (three or five), functions (limit, alarm, trend), and switching power.

Typical error percentage for linearity, hysteresis, and reproducibility with smooth surfaces.

Maximum resolution specified as 1 mm for FDU 80 sensors.

Details ambient temperature, storage temperature, shock resistance, climatic class, and ingress protection.

Specifies EMC requirements for AC and DC power supplies according to industry standards.

Details materials used for IP 66 housing, IP 40 housing, IP 10 plate, and separate operating unit.

Information on materials and weight for protective covers and post mounting accessories.

Describes the LCD display, LEDs for status and errors, and software counters.

Details handheld terminals, Commuwin II program, Rackbus RS 485, and synchronizing connection interfaces.

Lists AC and DC power supply options, power consumption, and ripple characteristics.

Mentions CE Mark confirmation of compliance with relevant EC directives.

Details available instrument versions for level, flow, and differential measurement.

Specifies certificate types, including Standard and CSA General Purpose.

Defines housing options: IP 66 field, IP 40 remote, and IP 10 panel mounting.

Describes various operation/display versions, with or without totaliser, for flow measurement.

Specifies relay options: three or five potential-free change-over contacts.

Lists available power supply options including AC and DC voltage ranges.

Details available interface and protocol options: none, INTENSOR, HART, or Rackbus RS-485.

Loading...

Loading...