Do you have a question about the Endress+Hauser Prosonic S FMU90 PROFIBUS DP and is the answer not in the manual?

| Measurement Principle | Ultrasonic |

|---|---|

| Output | PROFIBUS DP |

| Power Supply | 24 V DC |

| Protection Class | IP66/IP67 |

| Device Type | Ultrasonic Level Transmitter |

| Communication Protocol | PROFIBUS DP |

| Manufacturer | Endress+Hauser |

| Product Family | Prosonic S |

| Model | FMU90 |

| Enclosure Material | Aluminum |

| Application | Level measurement of fluids, pastes |

| Measuring Range | Up to 10 m |

| Accuracy | ±2 mm |

| Process Temperature | -40 to +80°C |

| Process Pressure | +0.7 to +3 bar |

| Display | 4-line backlit LCD |

Defines the intended use of the Prosonic S FMU90 transmitter.

Covers requirements for safe installation, commissioning, and operation.

Discusses measures for ensuring operational and process safety.

Instructions for mounting the polycarbonate field housing.

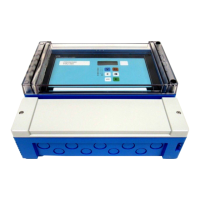

Instructions for mounting the aluminum field housing.

Instructions for mounting the DIN rail housing.

Instructions for installing the remote display and operating module.

Information on mounting the sensors and related documentation.

Checks to perform after the device has been mounted.

Conditions related to cable specifications for electrical connections.

Procedures for connecting the device to power.

Accessing the terminal compartment in the aluminum field housing.

Accessing the terminal compartment in the DIN rail housing.

Describes the terminal assignment for the device.

Details for terminals related to AC power supply.

Details for terminals related to DC power supply.

Details for terminals related to relay connections.

Details for terminals related to level inputs.

Special instructions for making electrical connections.

Instructions for connecting the power supply to the device.

Instructions for connecting the device to a PROFIBUS DP network.

Instructions for connecting the sensors to the device.

Instructions for potential equalization of metallic sensors in polycarbonate housing.

Instructions for potential equalization of metallic sensors in aluminum housing.

Steps for configuring the measuring device.

Setting up linearization for flow calculation.

Performing empty calibration for flumes and weirs.

Using "Check value" for interference echo suppression.

Configuring distance mapping for echo suppression.

Configuration of backwater and dirt detection functions.

Configuring simultaneous level and flow measurement with a single sensor.

Configuring limit value relays based on different types.

Configuring relays for alarms or diagnostics.

Configuring cyclic data exchange with automation systems.

Methods to protect device settings from unauthorized access.

General guidance and common issues for troubleshooting.

Troubleshooting steps for calibration errors.

Explains the meaning and structure of error codes.

A comprehensive list of error codes and their meanings.

Configuration options for relays and control functions.

Configuring pump control using limit settings.

Configuring pump control based on pump rate.

Extended basic setup for pump control (limit control).

Extended basic setup for pump control (rate control).

Managing sensor configurations.