3

5.0 INSTALLATION

Electric Motors Only

Note: Electrical connections should be made only by a

qualified electrician, adhering to all applicable local

and national codes.

1. Wiring — Make sure all power has been turned off.

Remove the cover from the magnetic starter switch.

Observe the diagrams on the inside cover of the starter

switch box for the correct wiring instructions and

connections. The 230V, 460V and 575V models differ

in the safety overload heaters and the wiring scheme.

2. Solenoid Valve Pendant (PER Models) — Attach

the pendant (see Fig. 8) to the solenoid valve using

the connector. Plug valve power cord into 115 VAC

outlet.

All Gasoline and Electric Models

3. Vent Plug — Turn the oil fill cap counterclockwise

one-quarter turn to vent reservoir. Failure to do so

will cause cavitation and damage to the pumping

mechanism may result.

4. Attaching Hoses — Thread hose(s) into 3/8” NPT

outlet port(s) of the valve, as shown in Fig. 1, “A.”

Use 1 1/2 wraps of Teflon tape on the hose fitting,

leaving the first thread completely free of tape, as

shown in Fig. 2, “B.” Pumps with 3-way valves have

one outlet port, and pumps with 4-way valves have

two outlet ports. All hoses and components used

with this pump must have a working pressure rating

higher than, or equal to, the maximum pressure

rating of the pump (10,000 psi).

Figure 1

Figure 2

B

5. Oil Level — Check the

oil level of the pump

prior to start-up, and

add Enerpac hydraulic

oil, if necessary. Oil

level should be at the

top of the sight gauge,

and should never fall

below visible level. If

it does, pump damage

may occur (see Fig. 3).

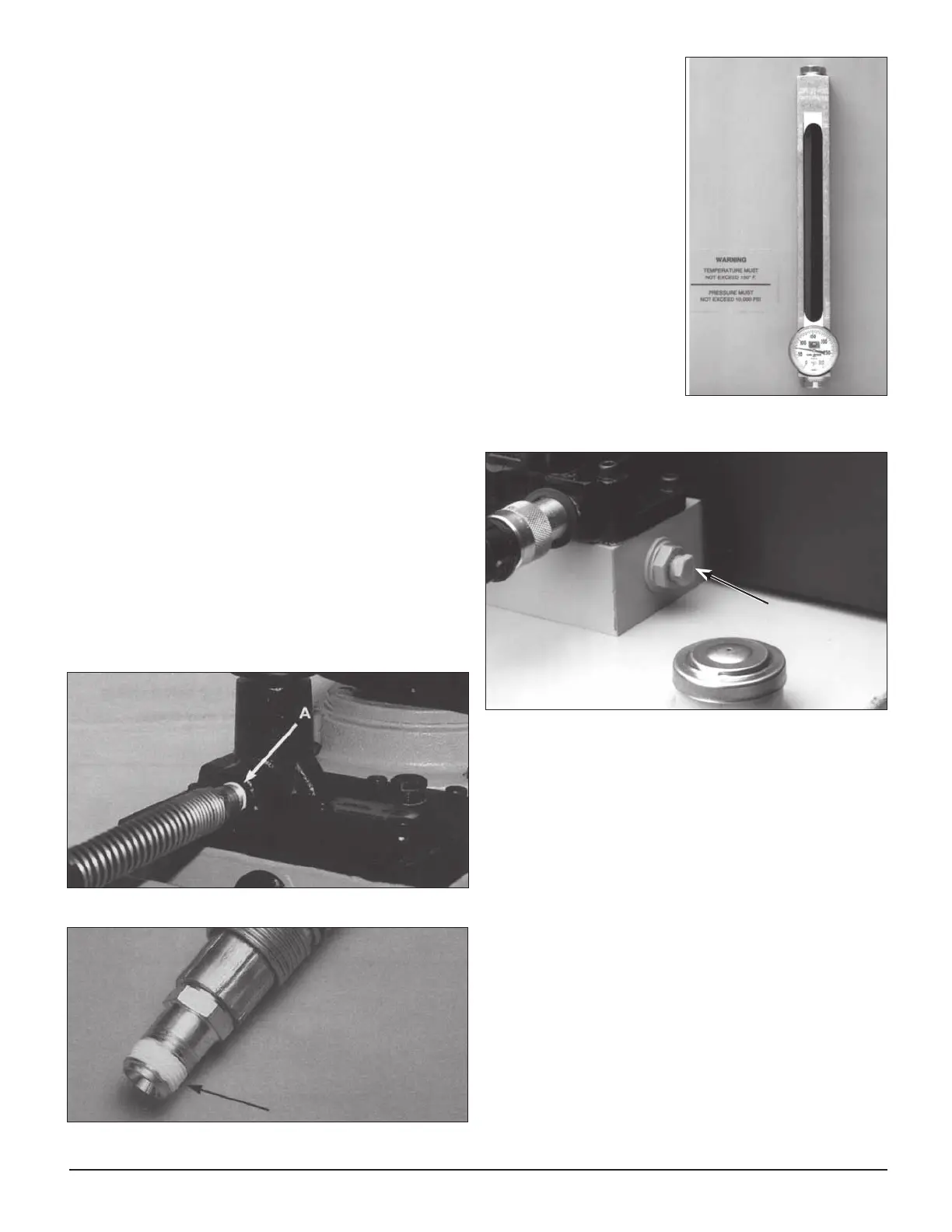

6. Return-to-tank port

— A 3/8” NPT port is

provided on side of

valve mounting block,

as shown in Figure 4,

for connecting tank

lines from remote

valves.

NPT Port

Figure 4, Valve Mounting Block

6.0 OPERATION

1. Check oil level of pump and add oil if required. Make

sure the pump reservoir is vented. (See 5.0 Installation,

step 5).

2. Shift manual valves to the neutral position before

starting pump. If equipped with an electric valve,

when neither the advance or retract buttons are

pushed, valve is in the neutral position. (See step 5,

Valve Operations.)

Electric Motors

3. The power switch is located on the starter box on the

side of electric motor. When initially starting electric

models, it may be necessary to jog the motor by

pushing the start and stop buttons quickly several

times to prime the piston pump.

Gasoline Engines

4. Fill fuel tank with regular unleaded gasoline. Replace

fuel cap and wipe any spilled gasoline from engine

and fuel tank. Check engine oil level and add/fill as

required.

Figure 3, Sight Gauge

Loading...

Loading...