5

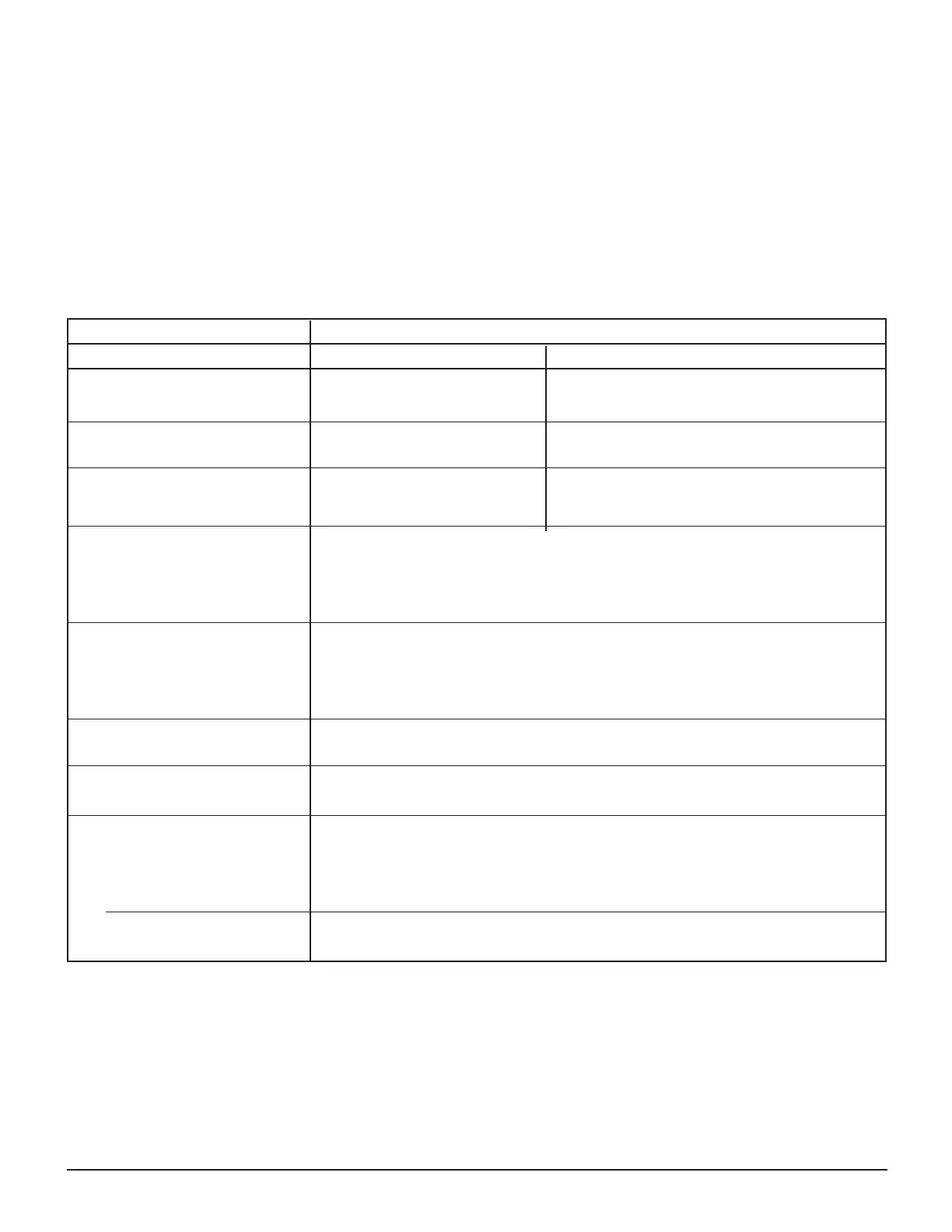

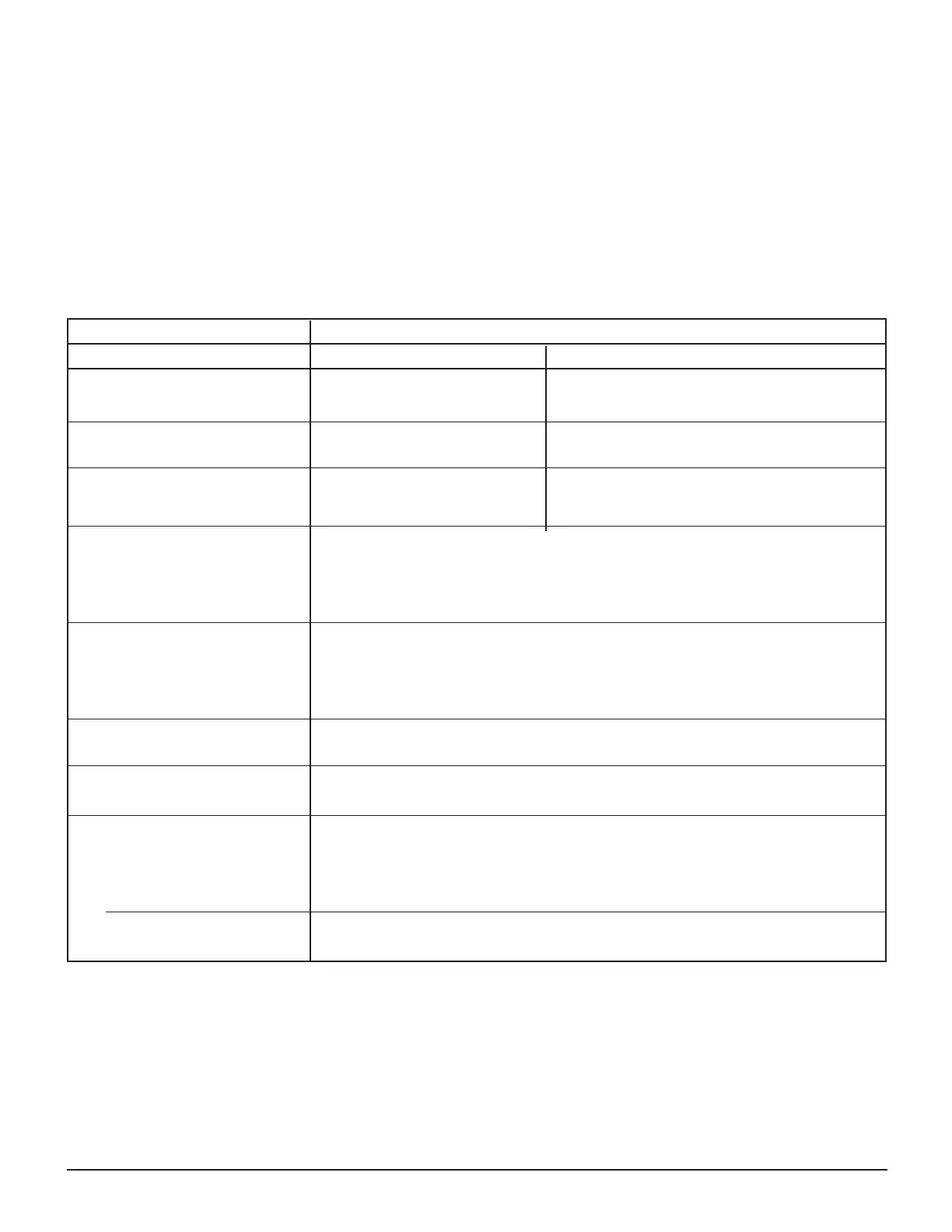

8.0 TROUBLESHOOTING

Only qualified hydraulic technicians should service the

pump or system components. A system failure may

or may not be the result of a pump malfunction. To

determine the cause of the problem, the complete system

must be included in any diagnostic procedure. The

following information is intended to be used only as an

aid in determining if a problem exists. For repair service,

contact the authorized Enerpac Service Center in your

area. For the location of an Enerpac Service Center in

your area, go to www.enerpac.com.

SYMPTOM POSSIBLE CAUSE

Electric Models Gasoline Models

Pump will not start No power or low voltage Low on fuel or dead battery

Fouled spark plugs

Motor stalls under pressure Low voltage Throttle not fully open

Check engine operator’s manual

Electric valve will not operate No power or wrong voltage

Low voltage ————————

Valve out of adjustment

Pump fails to build pressure Piston pump lost prime

External leak in system

Internal leak in pump

Internal leak in valve

Internal leak in system component

Pump builds less than full pressure Relief valve set low

External system leak

Internal leak in pump

Internal leak in valve

Internal leak in system component

Pump builds full pressure, Load greater that cylinder capacity at full pressure

but load does not move Flow to cylinder blocked

Cylinder drifts back on its own External system leak

Internal leak in a system component

Cylinder will not return:

Single-acting type Valve malfunction

Return spring broken

Return flow restricted/blocked

No load on a “load return” cylinder

Double-acting type Valve malfunction

Return flow restricted/blocked

Loading...

Loading...