4

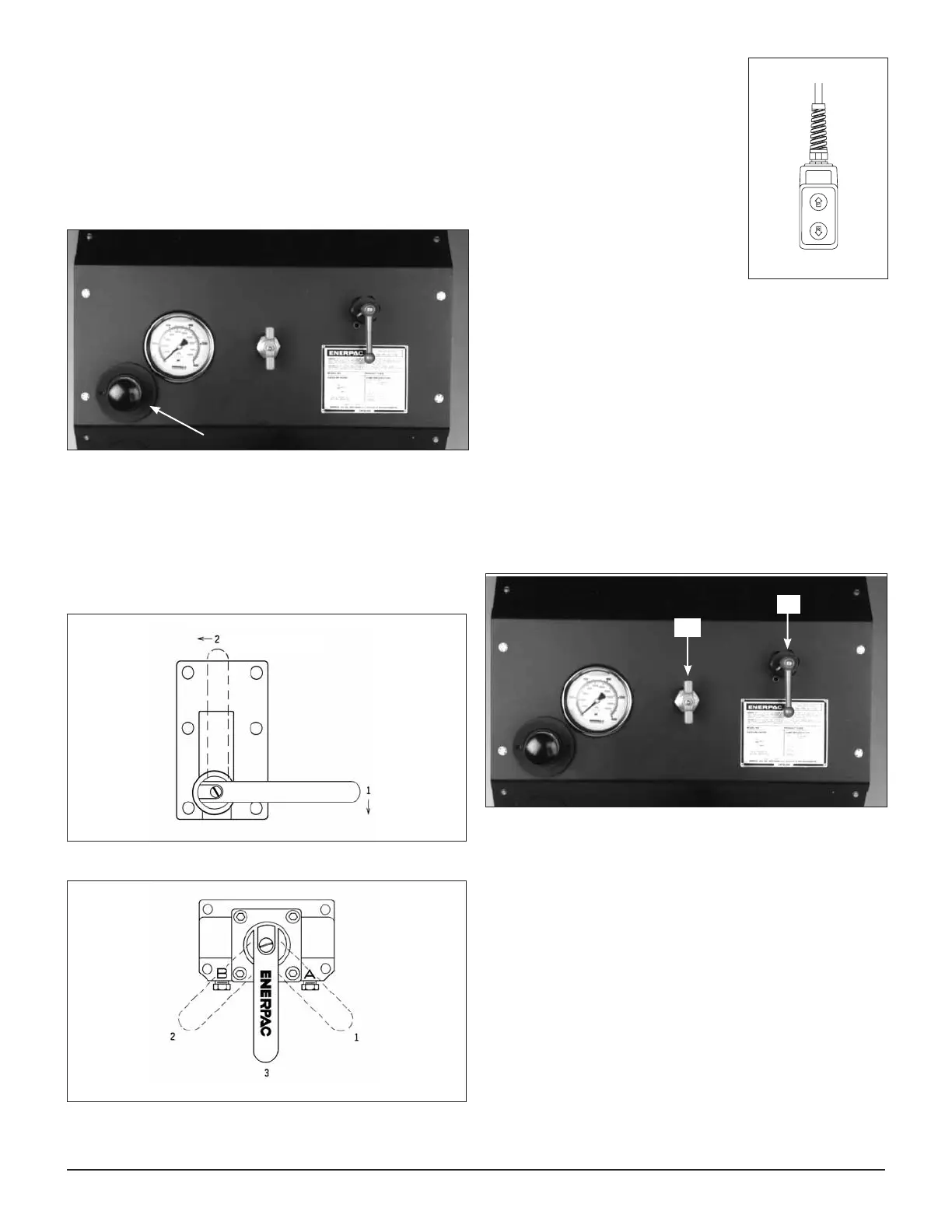

When starting gasoline engine models after

transporting or after removing from storage, it will be

necessary to operate priming pump on left front of

instrument panel (see Figure 5). Pull knob on priming

pump out and push in several times to push oil into

pump assembly and fill intake line.

Refer to Manufacturer’s operating manual supplied

with pump for starting and operating procedure for

gasoline engine.

Figure 5

5. Valve Operation — Listed below are the valve

positions and operations.

6. Relief Valve Adjustment — The pumps are equipped

with two relief valves. One is a safety relief, factory

set and must not be adjusted or repaired, except by

an Authorized Enerpac Technical Service Center.

Figure 6, VM-2

Retract/Neutral

Advance

Figure 7, VM-4

Advance

Neutral/Hold

Retract

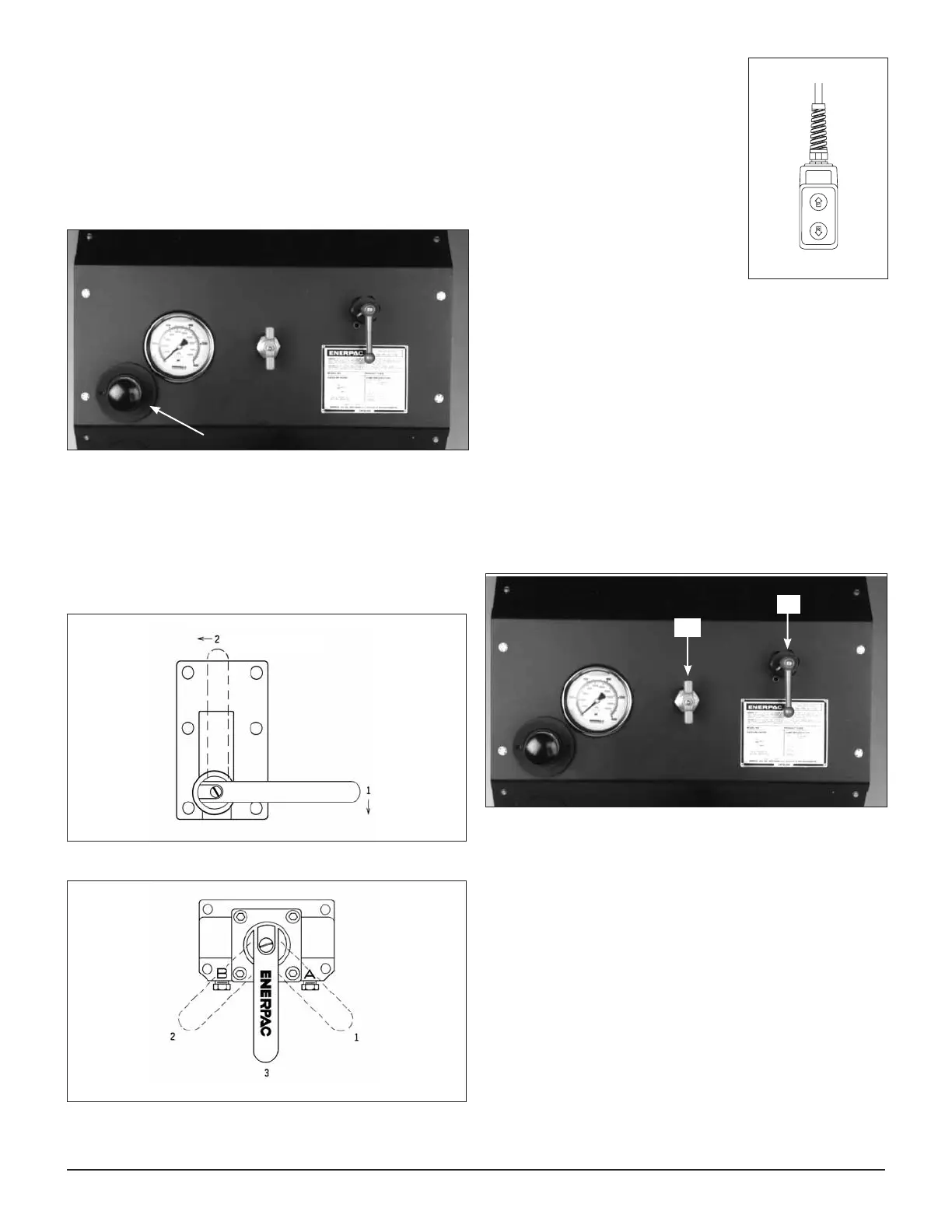

The other is an adjustable

relief valve. It is located on

the right side of the instrument

panel, and has an adjustment

range of 1000-10,000 psi. Turn

handle clockwise to increase

pressure, and counterclockwise

to decrease pressure. Turn

wing nut on adjustment screw

down to help maintain set

pressure. Use the gauge on

the instrument panel to monitor

the pressure setting as shown

in Fig. 9.

NOTE: The adjustable relief valve

should never be bottomed

out. When bottomed out, premature wear of the

adjustable relief valve will result. For a more accurate

setting, lower pressure below the final setting and

then increase slowly to the final setting. Do not set

the adjustable relief valve above 10,000 psi.

7. Gauge Shut-off Valve — Located in the center of

the instrument panel is the gauge shut-off valve,

as shown in Fig. 9, “B.” It can used to dampen

pulsations or to disable gauge when system pressure

has been established, which will extend the life of the

gauge.

Figure 9

A

B

7.0 MAINTENANCE

1. Maintaining proper oil level. Check the oil level of the

pump prior to start-up, and add Enerpac hydraulic

oil, if necessary, by removing the oil fill cap. (Refer

to 5.0 Installation, step. 5)

2. Change oil every 250 hours, or more frequently if

used in dirty environments. The plug on the lower

front side of the reservoir serves as a drain port.

3. Check all system components for leaks. Repair or

replace leaking components.

Figure 8, IC-43

Pendant (PER

models only)

Loading...

Loading...