A C-TRAC2.1 MANUAL

IOM-12 Page 14 March 1999 R1

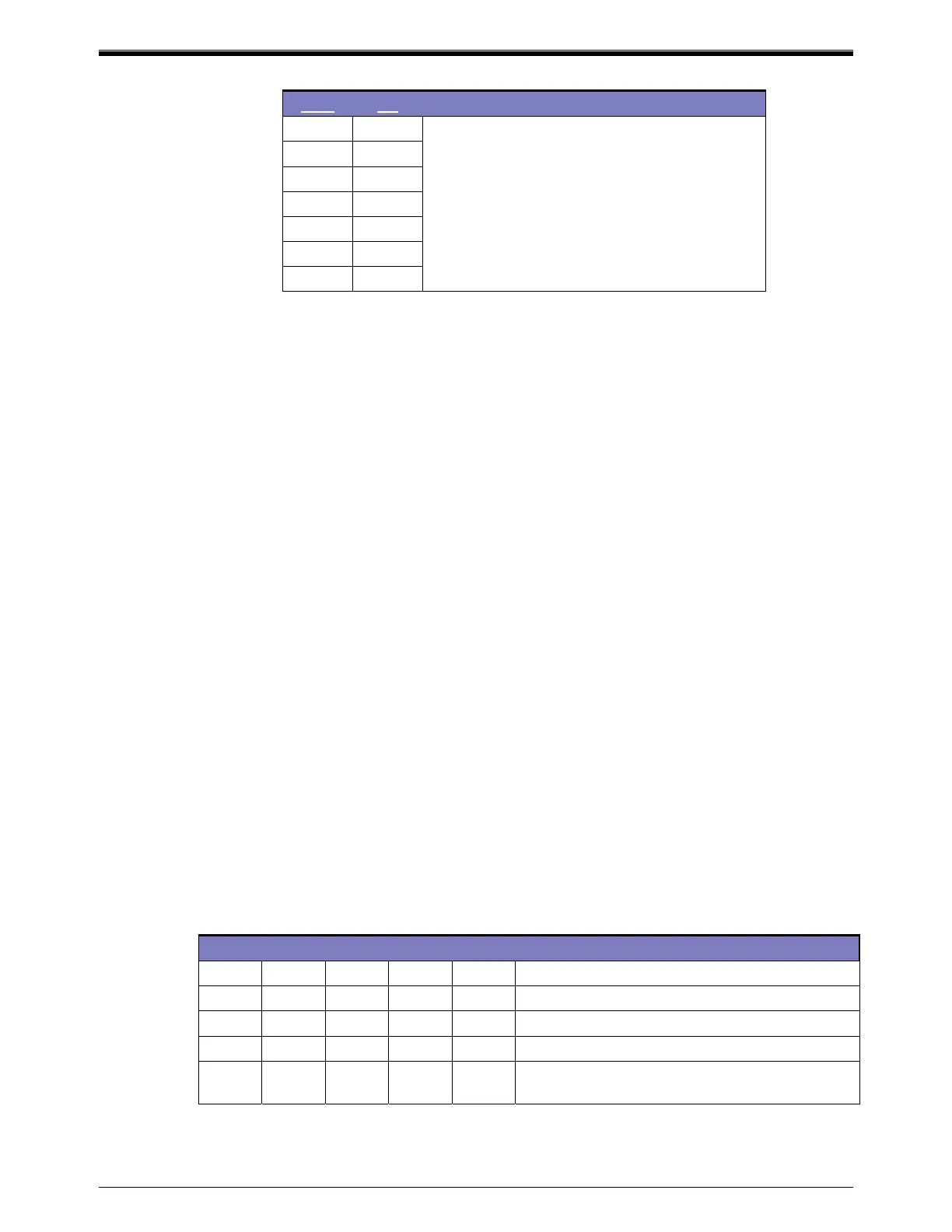

VDC Ma

0

0

2

3

Note: Zero reset considered to be about 5.5 VDC

or 12 ma less is resetting down to cooler

discharge greater is resetting up to warmer

discharge

4

8

5

10

6

12

8

16

10

20

Calibration Method 1

Remove the discharge sensor and install a 1000-ohm 1% ¼ watt resistor in place of the sensor.

Adjust the discharge set point until the internal time delay activated light goes off, and is mid way

between the two on points. Set the incoming signal to either 12 ma or 5.5 VDC. Turn on dipswitch 5.

Gradually adjust pot 10 (mounted on the underside of the board) until the internal time delay activated

light goes off, and is mid way between the two on points.

Calibration Method 2

Install the temperature simulator pot and adjust the simulator temperature pot until the internal time

delay activated light goes off, and is mid way between the two on points. Set the incoming signal to

either 12 ma or 5.5 VDC. Turn on dipswitch 5. Gradually adjust pot 10 (mounted on the underside of the

board) until the internal time delay activated light goes off, and is mid way between the two on points.

XVIII. CALCULATED SET-POINT

The calculated set point is an internal calculation of the C-TRAC electronics. If no reset devices are

activated (dipswitches 2, 3, 4, 5 are off). The calculated set point and set point knob are the same value. If,

however, one of the reset functions is activated, the calculated set point also includes the affect of that

reset devices desire to adjust the set point up or down.

XIX. DISCHARGE TEMPERATURE SENSING

A duct sensor senses discharge temperature. There are often two discharge sensors on the C-TRAC, one

for heat control and one for cool control. A relay will switch between them. This is to avoid hunting

problems introduced by the thermal mass of the cooling coil.

XX. SET-POINT CALIBRATION

Set point calibration should not need to be done as it was set at the factory. The Johnson Control TE 6000-

960 and the TE 6100-960 combination set point and sensor is pre-calibrated at Johnson's factory. The

Engineered Air C-TRAC2.1 has been calibrated at the Engineered Air factory.

1. To determine what control options this C-TRAC is configured to operate with check the wiring diagram,

control function, or C-TRAC dipswitch settings. The types of control are listed below.

2. Locate the dipswitches under the removable cover. Write down their present settings. After calibration

return the switches to their original settings.

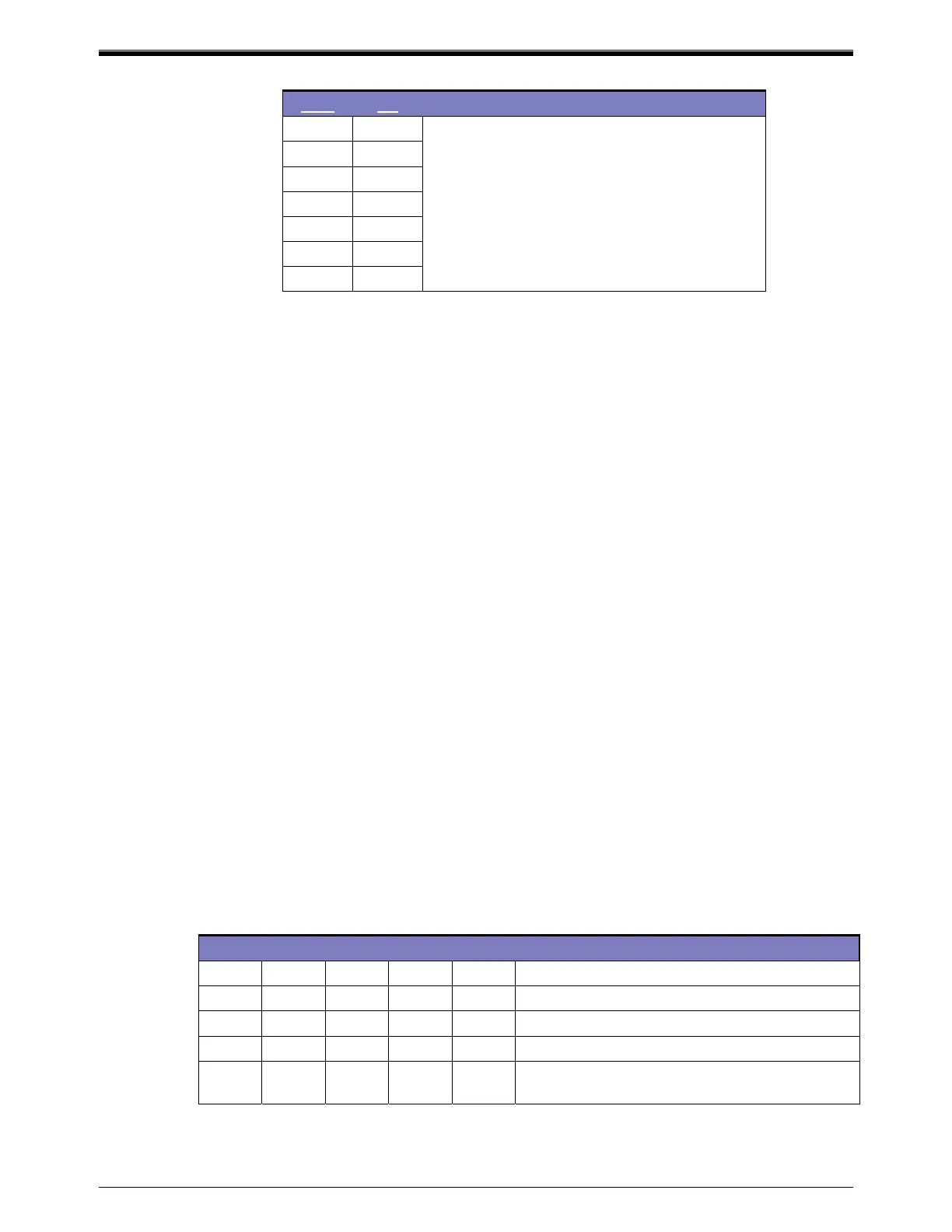

SW1 SW2 SW3 SW4 SW5 REMARKS

On

Off Off Off Off Discharge control

Off

On Off Off Off Room control (not recommended)

On

Off On Off Off Discharge control c/w room or return reset

On

Off Off On Off Discharge control c/w ambient reset

On

Off Off Off On

Discharge control c/w 4-20 ma, 0-10 VDC or

vane position reset

Calibrate the required individual sensor and set points combination in the following order. Do not attempt to

calibrate any application listed below that is not part of your application.

Loading...

Loading...