19 20

Here user could set the maximum power for each phase. For example, if the user sets

the power value on phase A to 600W on app, and a microinverter with 2 DC inputs is

connected to phase A, then each MPPT can send a maximum of 600W/2 = 300W

power; if there are 2 microinverters with 2 DC inputs, each MPPT on phase A can

generate a maximum of 600W/4 = 150W.

Note: If the user set the Automatic control in the Grid power control panel and

haven’t switched to the Manual control. Even if a specific power percentage is set in

the parameter setting >>>standard selection>>>Power Setting, firstly the microin-

verter will generate power according to the specific power set, but the maximum

microinverter power will be re-adjusted according to the value of Automatic control

in about 5 minutes.

Step2. Click confirm button.

4.3.4 Others

To know more about EnverView, please refer to EnverView App User Guide (End User)

on our website www.envertec.com

5.1 Safety Checks

Safety checks should be performed at least every 12 months by manufacturer’s

qualified person who has adequate training, knowledge, and practical experience to

perform these checks. The data should be recorded in an equipment log. If the device

is not functioning properly or fails in any of the tests, the device has to be repaired.

NOTE

The “Note” mark in this manual indicates important

product information.

WARNING

Do not attempt to repair the Envertech monitoring

device without authorization, because it does not

contain parts available for users to repair. If the microin-

verter fails, please contact Envertech customer service.

5.2 Maintain Periodically

For more information of safety checks, please see below the three safety instructions

of this manual.

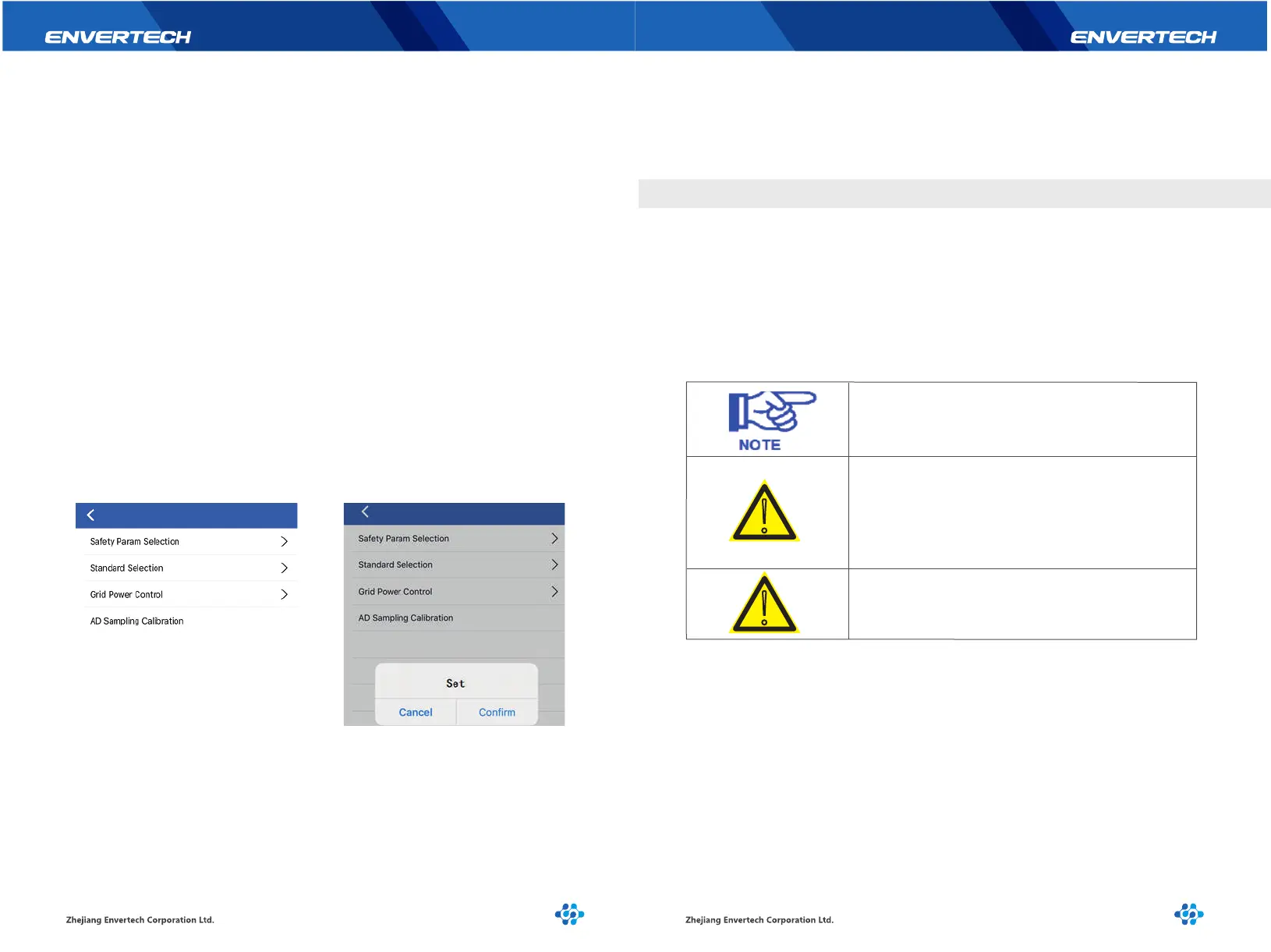

Step3. Enter Safety Param Selection

There are two control modes here. Input the upper power limit you need and click

5 Basic operations

WARNING

Please ensure that all power is off and there is no electric

current when connecting Envertech monitoring device.

!

!

D. AD Sampling Calibration

Introduction:

In order to ensure the accuracy of sampling, it is necessary to calibrate the sensor for

the first time to ensure the accuracy of zero current voltage, so that the difference

between sampling voltage and zero current voltage is accurate, and determine the

current size according to the scale table corresponding to the sensor. Generally, it only

needs to be calibrated once, and then it doesn't need to be recalibrated.

Operation Step:

Step1. Enter AD Sampling Calibration

Loading...

Loading...