ENVIRO-TEC

13

FORM ET115.24-NOM12 (718)

WATER SYSTEM BALANCING

A complete knowledge of the hydronic system, its

components, and controls is essential to proper water

system balancing and this procedure should not be

attempted by unqualied personnel. The system must

be complete and all components must be in operating

condition BEFORE beginning water system balancing

operations.

Each hydronic system has different operating

characteristics depending on the devices and controls

in the system. The actual balancing technique may vary

from one system to another.

After the proper system operation is established, the

appropriate system operating conditions such as various

water temperatures and ow rates should be recorded

in a convenient place for future reference.

Before and during water system balancing, conditions

may exist which can result in noticeable water noise

or undesired valve operation due to incorrect system

pressures. After the entire system is balanced, these

conditions will not exist on properly designed and

balanced systems.

CONTROLS OPERATION

Before proper control operation can be veried all other

systems must be in proper operation. The correct water

and air temperatures must be present for the control

function being tested. Some controls and features are

designed to not operate under certain conditions.

A wide range of controls and electrical options and

accessories may be used with the equipment covered

in this manual. Consult the approved unit submittals,

order acknowledgement, and other manuals for detailed

information regarding each individual unit and its

controls. Since controls and features may vary from

one unit to another, care should be taken to identify

the controls to be used on each unit and their proper

control sequence information provided by component

manufacturers such as submittals and installation,

operation, and maintenance manuals of their individual

controls is available upon request.

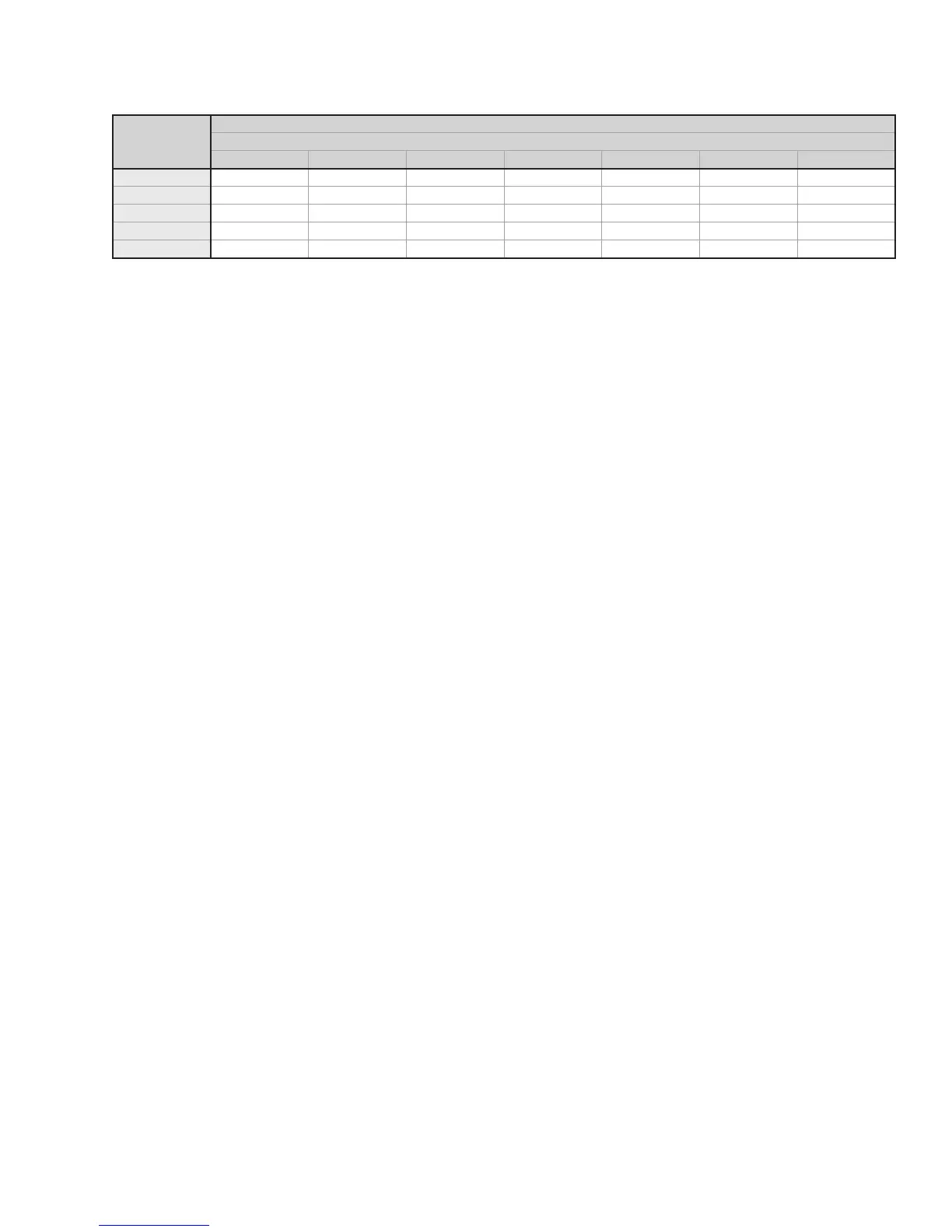

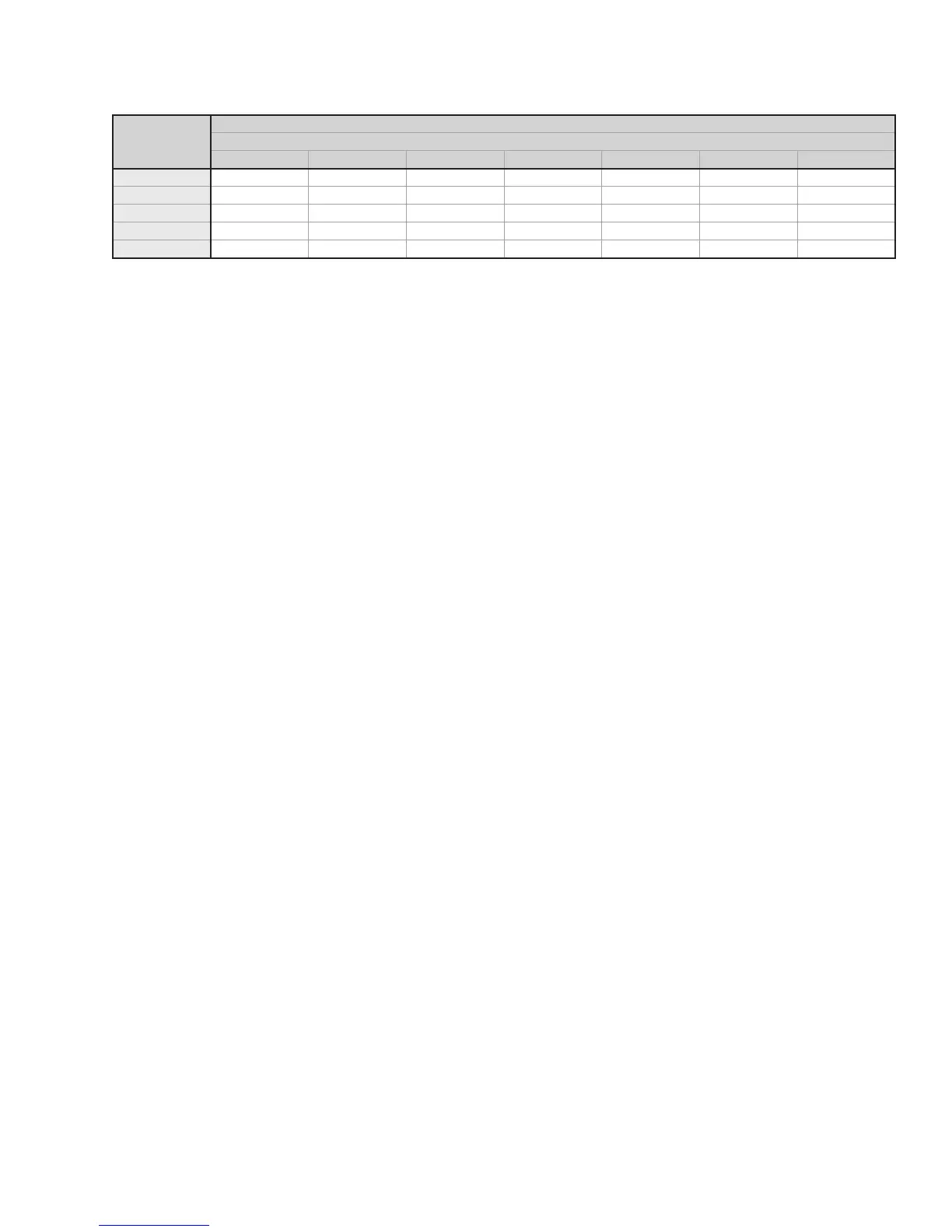

TABLE 2: EC MOTORS

HORSEPOWER

MAXIMUM MOTOR AMPERAGE

VOLTAGE/PHASE

115/1 208/1 230/1 277/1 208/3 230/3 480/3

1/2 7.7 5.0 5.0 4.1 2.0 2.0 1.0

1 12.8 9.4 9.4 6.9 3.7 3.7 1.7

1-1/2

3

– – – – 4.4 4.4 2.2

2

3

25.6 18.8 18.8 13.8 7.4 7.4 3.4

3

3

-- -- -- -- 8.8 8.8 4.4

NOTES:

1. Actual motor nameplate AMPs may vary, but will not exceed values shown.

2. Consult factory for applications requiring special motors.

3. Amp values are total amp values for (2) motors.

Loading...

Loading...