13

12

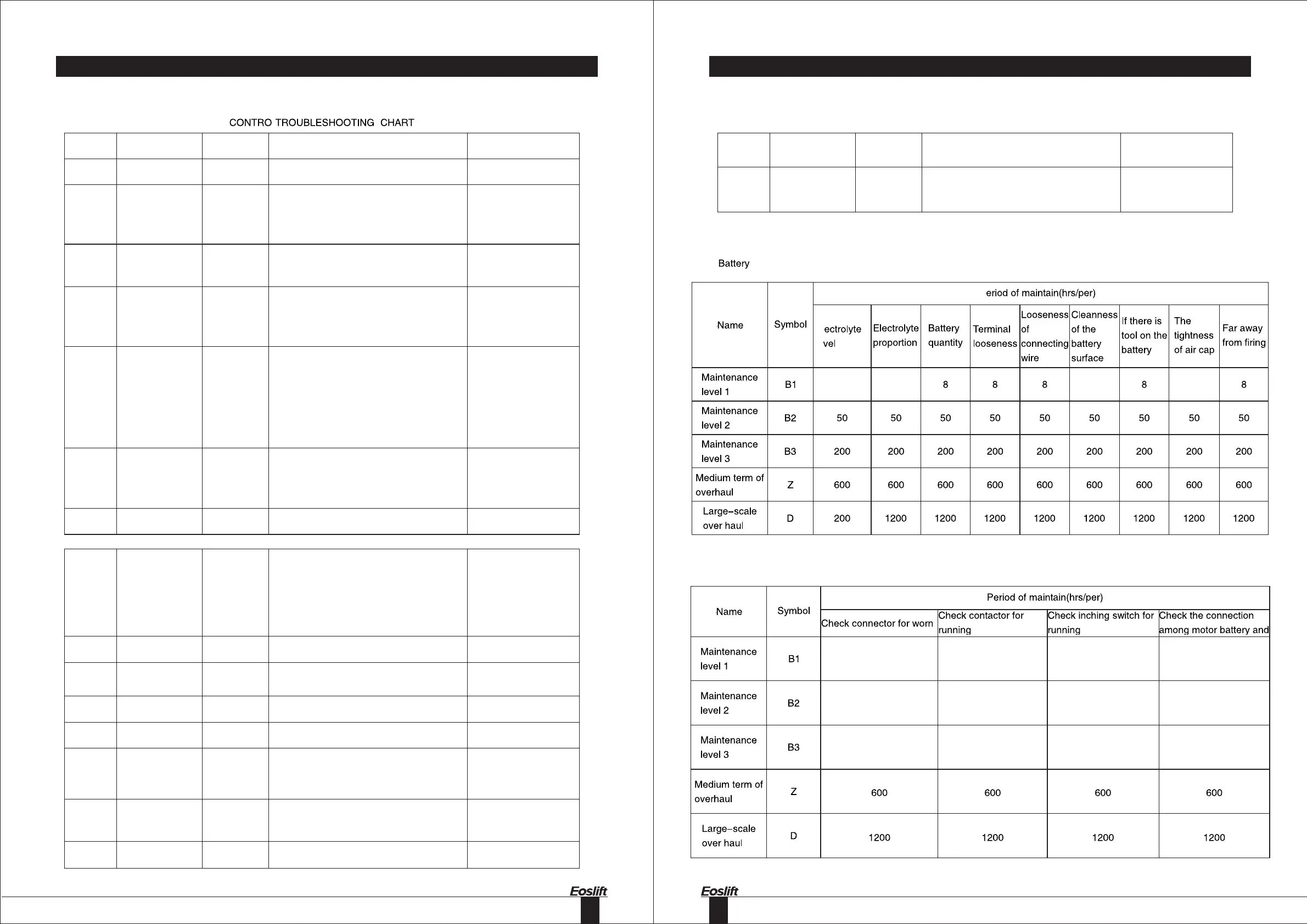

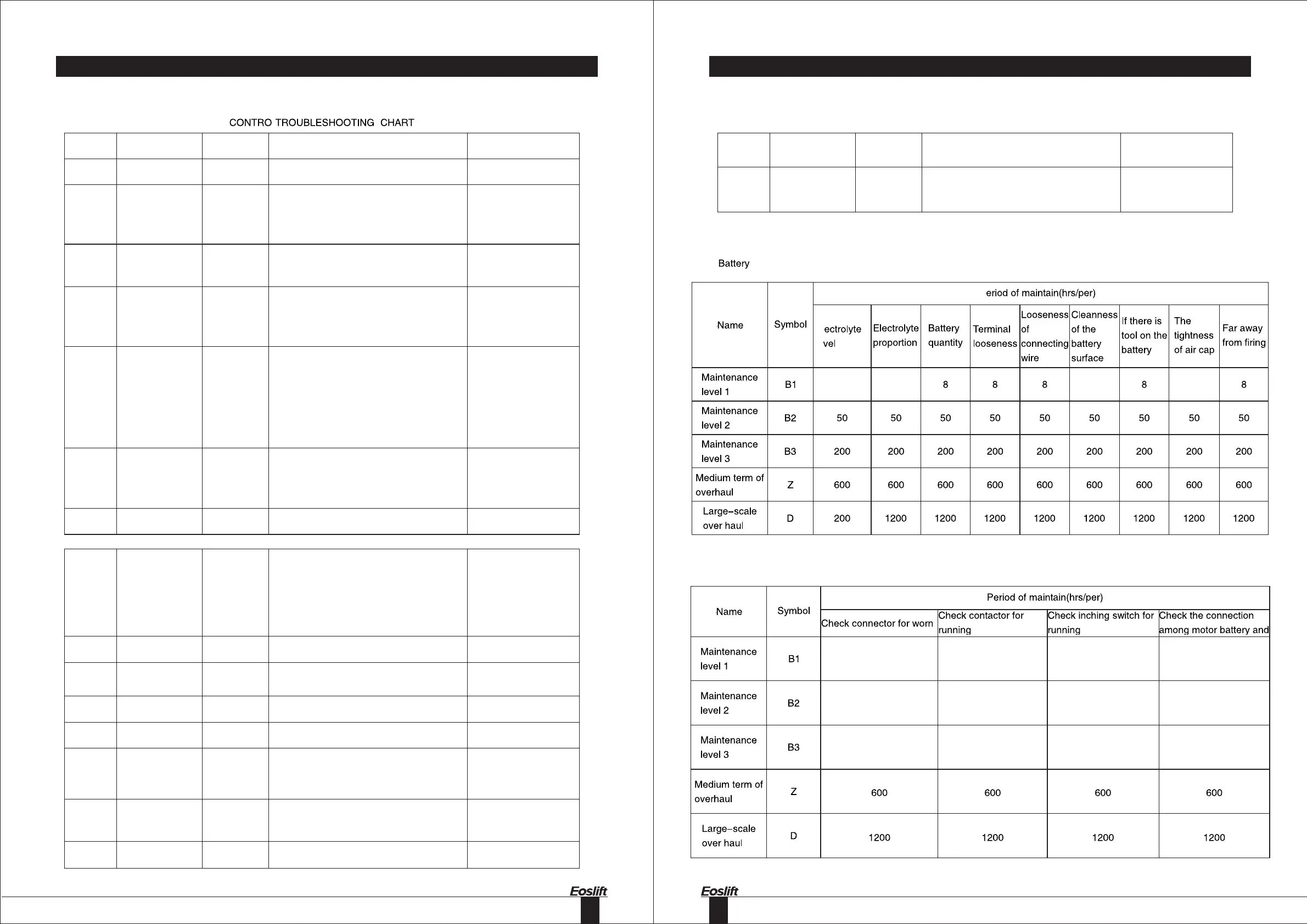

5.4 Maintenance List

LED

CODE

0.1

1.1

1.2

1.3

1.4

2.1

2.2

2.3

2.4

3.1

3.2

PROGRANNER

LCD DISPLAY

NO KNOWN

FAULTS

FAULT

CATEGORY

0

CURRENT SHUNT

FAULT

HW FAILSAFE

M-SHORTED

SRO

THROTTLE

WIPER HI

EMR REV

WIRING

HPD

SRVC TOTAL

SRVC TRAC

TOTAL

DISABLED

TRAC DISABLE

THROTTLE

WIRPERLO

FIELD SHORT

MAIL CONT

WELDED

POSSIBLE CAUSE

N/A N/A

FAULT CLEARANCE

1

1

1

3

1

1

3

3

3

3

3

1

1

1

1. Abnormal vehicle operation

causing high current spikes

2. Current sensor out of range

3. Controller failure

1. Noisy environment

2. Self-test or watchdog fault

3. Controller failure

1. Inernal or external short of M-to B-

2. Incorrect motor wiring

3. Controller failure

1. Improper sequence of KSI,interlock

and direction inputs

2. Interlock or direction switch circuit

open

3. Sequencing delay too short

4. Wrong SRO of throttle type selected

5. Misadjusted throttle pot

1. Throtte input wire open or shorted to

B+

2. Defective throttle pot.

3. Wrong throttle type selected

1. Improper sequence wire or wire open

1. Improper sequence of KSI,interlock,

and throttle inputs

2. Misadjusted throttle pot

3. Sequencing delay too short

4. Sequencing delay too short

5. Wrong HPD or throttle type selected

1. Total maintence timer expired

1. Traction maintenance timer expired

1. Total disable timer expired

1. Traction disable timer expired

1. Throttle pot wire open of shorted to B+

2. Wrong throttle type selected

3. Defective throttle pot

1. Main contactor coil shorted

2. Field winding shorted to B+ or B-

3. Field resistance too low

1. Main contactor stuck closed

2. Main contactor driver shorted

Cycle KSI. if problem

persists, replace the

controller

Cycle KSI. if problem

persists, replace the

controller

Check wiring;Cycle

KSI.

if problem persists,

replace the controller

Follow proper

sequence;

adjust throttle if

necessary;

adjust programmable

parameters if

necessary

When Throttle wiper

high

input returns to valid

range

Re-apply emergency

reverse or cvcle interlock

Follow proper sequence;

adjust throttle if

necessary;

adjust programmable

parameters if necessary

Reset with proqrammer

Reset with proqrammer

Reset with proqrammer

Reset with proqrammer

When throttle Wiper

Low

input returns to valid

range

Check contactor coil

and

field winding;cycle KSI

Check wiring and

contactor; cycle KSI

3.3

3.4

FIELD OPEN

1

1

MISSING

CONTACTOR

1. Field winding connection open

2. Field winding open

1. Main contactor coil open

2. Main contactor missing

3. Wire to main contactor open

Check wiring and

cycle KSI

Check wiring and

cycle KSI

Loading...

Loading...