Safety and operating instructions

© Construction Tools GmbH | 3390 5201 01 | 2023-05-15

Original Instructions

43

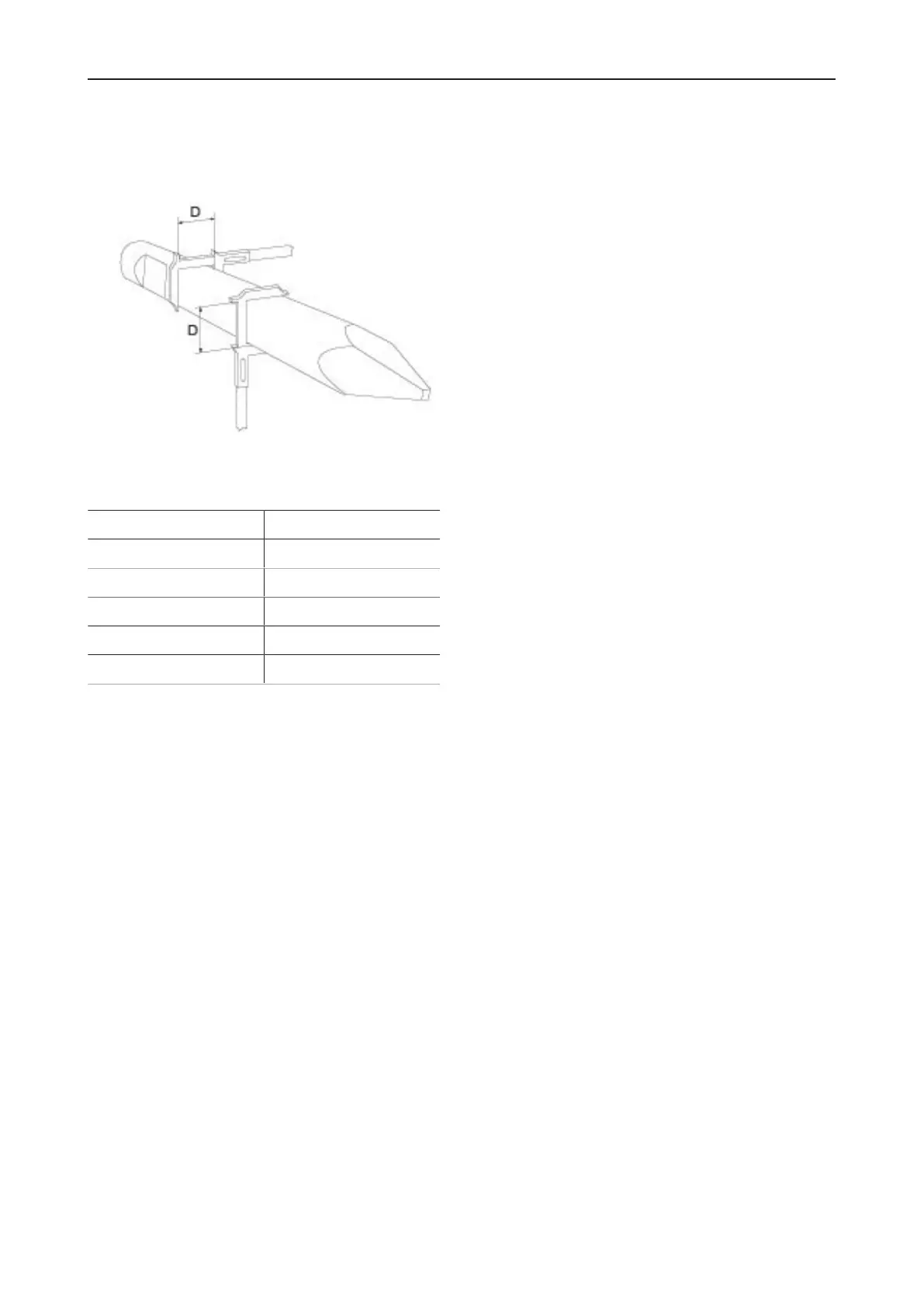

n

Check the shaft of the working tool for wear when-

ever replacing it, but at least once every 100operat-

ing hours.

n

Replace the working tool if the shaft has worn to the

minimum diameter D

min

stated below.

Type D

min

MB750 E 97 mm (3.82in.)

MB1000 E 106 mm (4.17in.)

MB1200 E 116 mm (4.57in.)

MB1500 E 131 mm (5.16in.)

MB1650 E 137 mm (5.39in.)

7.7 Checking the retainer bars

n

Check both retainer bars whenever replacing working

tools.

n

Rework or replace the retainer bars if you find any

signs of wear, such as sharp edges, notches or se-

vere erosion.

n

Deburr the retainer bars by careful grinding.

n

Install the retainer bars in their reversed orientation if

they cannot be reworked anymore.

n

Replace the retainer bars if both sides cannot be re-

worked anymore.

n

Check both plugs for the retainer bars.

The plugs must not be damaged.

7.8 Checking the percussion

piston impact surface

n

Check the percussion piston impact surface when-

ever replacing the working tool, but at least once ev-

ery 100operating hours to make sure it is not

chipped and has no visible cracks.

n

Use an electric torch to illuminate the surface of the

dismantled working tool.

n

Do not use the hydraulic breaker again if you have

found the surface to be chipped or cracked.

n

Consult the Epiroc Customer Center / Dealer in your

area.

Loading...

Loading...