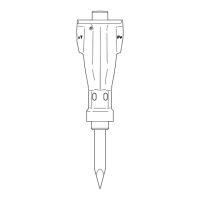

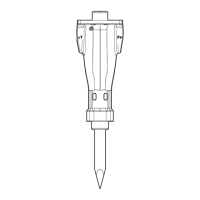

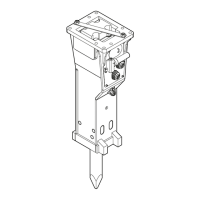

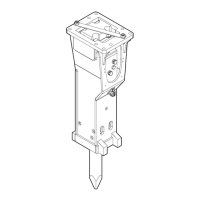

What to do if the impact mechanism of my Epiroc Secoroc COP 32 is not working properly?

- MMichele WarrenAug 5, 2025

If the impact mechanism in your Epiroc Industrial Equipment isn't working or is weak, start by checking the air pressure and ensuring all air passages to the hammer are clear. Also, verify that oil is reaching the impact mechanism; if not, lubricate it properly. If these steps don't resolve the issue, the hammer may be clogged with dirt, some parts could be worn or damaged. In such case you should disassemble the hammer and wash all components, replace worn parts, compression ring, buffer rings in the cover, or O-rings in bit bushing.