U Page 6

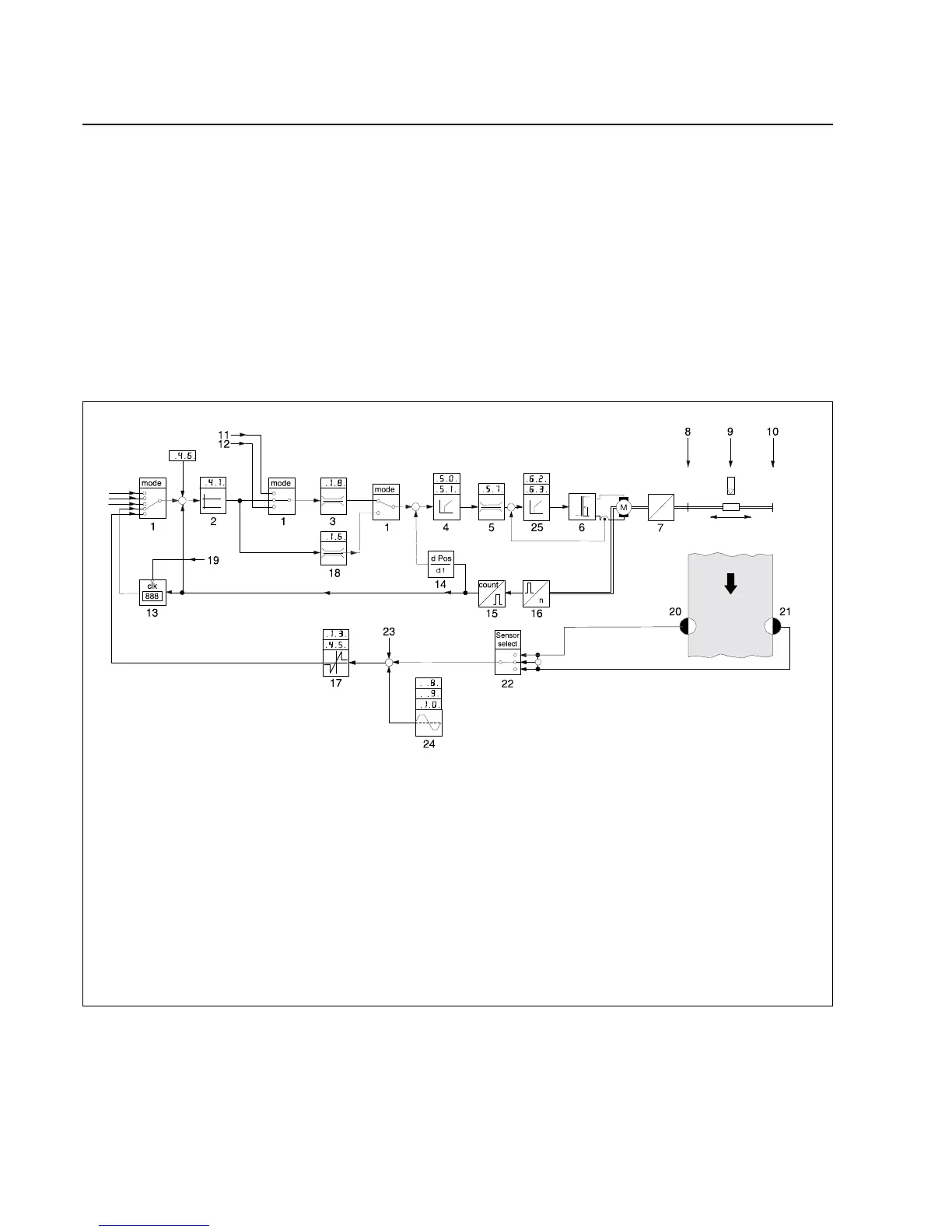

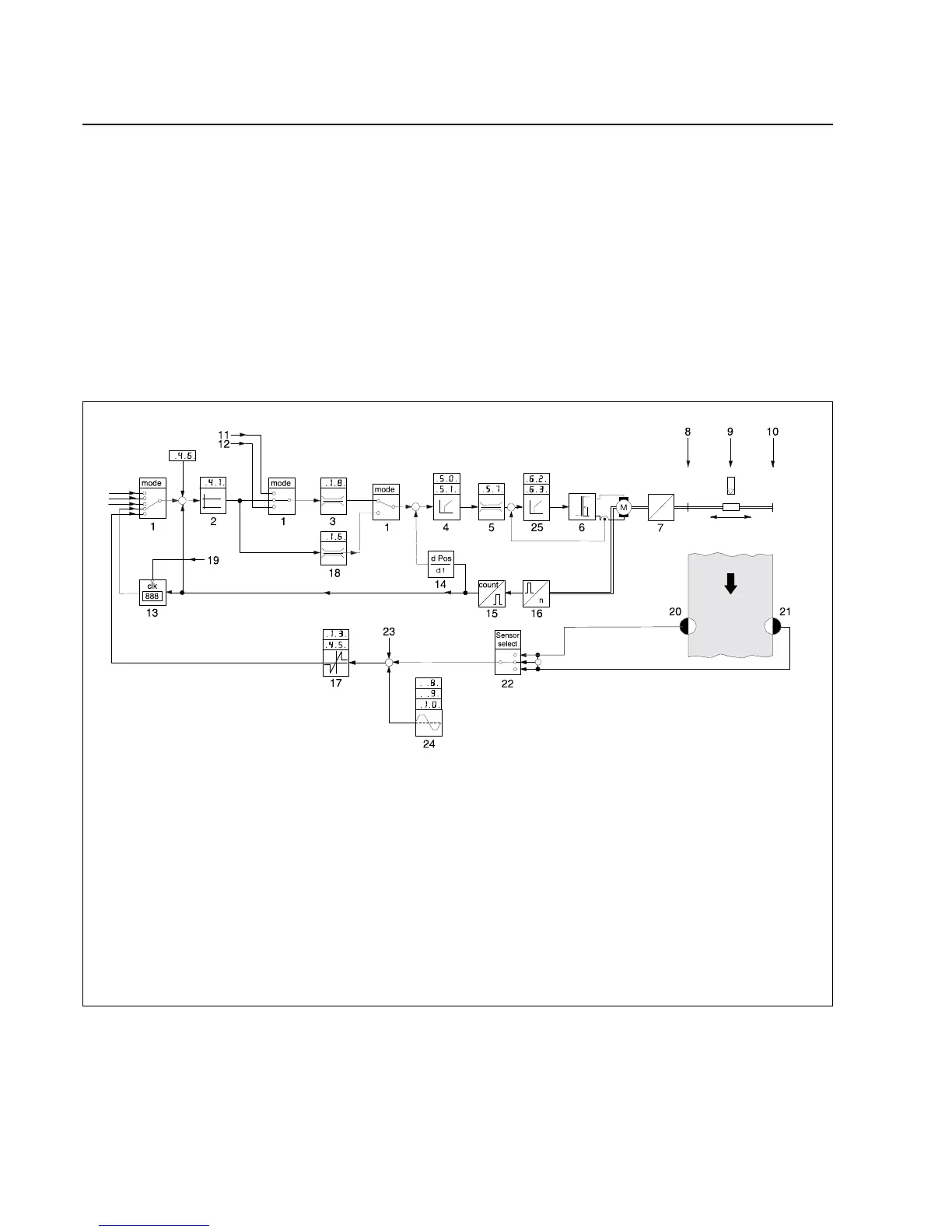

Digital controller RK 4004

Control structure legend

1 Operating mode

2 Actuator position controller

3 Max. variable actuating speed in manual

4 Speed controller

5 Variable current controller

6 Power output stage

7 Gearing with spindle

8 Right end position

9 Center position

10 Left end position

11 Right offset

12 Left offset

13 Actual position memory

14 Actual speed value recording

15 Counter

16 Incremental encoder

17 Web position controller

18 Max. variable actuator speed in automatic

19 Memory command at stop

20 Right edge sensor

21 Left edge sensor

22 Sensor selection (right web edge, left web edge, web center)

23 Web offset

24 Oscillation generator

25 Current controller

1.6 Control structure with con-

stant controlling for inte-

gral actuators

In the case of a control structure for integral actuators the web actual

position value is compared to the required web set position value

and, in the event of a deviation, it is transmitted as a control diffe-

rence to a P position controller. The latter provides the necessary set

position value for the actuator. The current actual actuator position

value is compared to the required set position value and transmitted

as a control difference to the actuator position controller. The latter

generates the set speed value which is compared to the actual speed

value, the difference being fed to the PI speed controller which emits

a pulse width-modulated signal at the output stage.

Available integral actuators:

SWS segmented roller guider, VGA pivoting roller, BCS edge and

width spreader

Loading...

Loading...