U Page 8

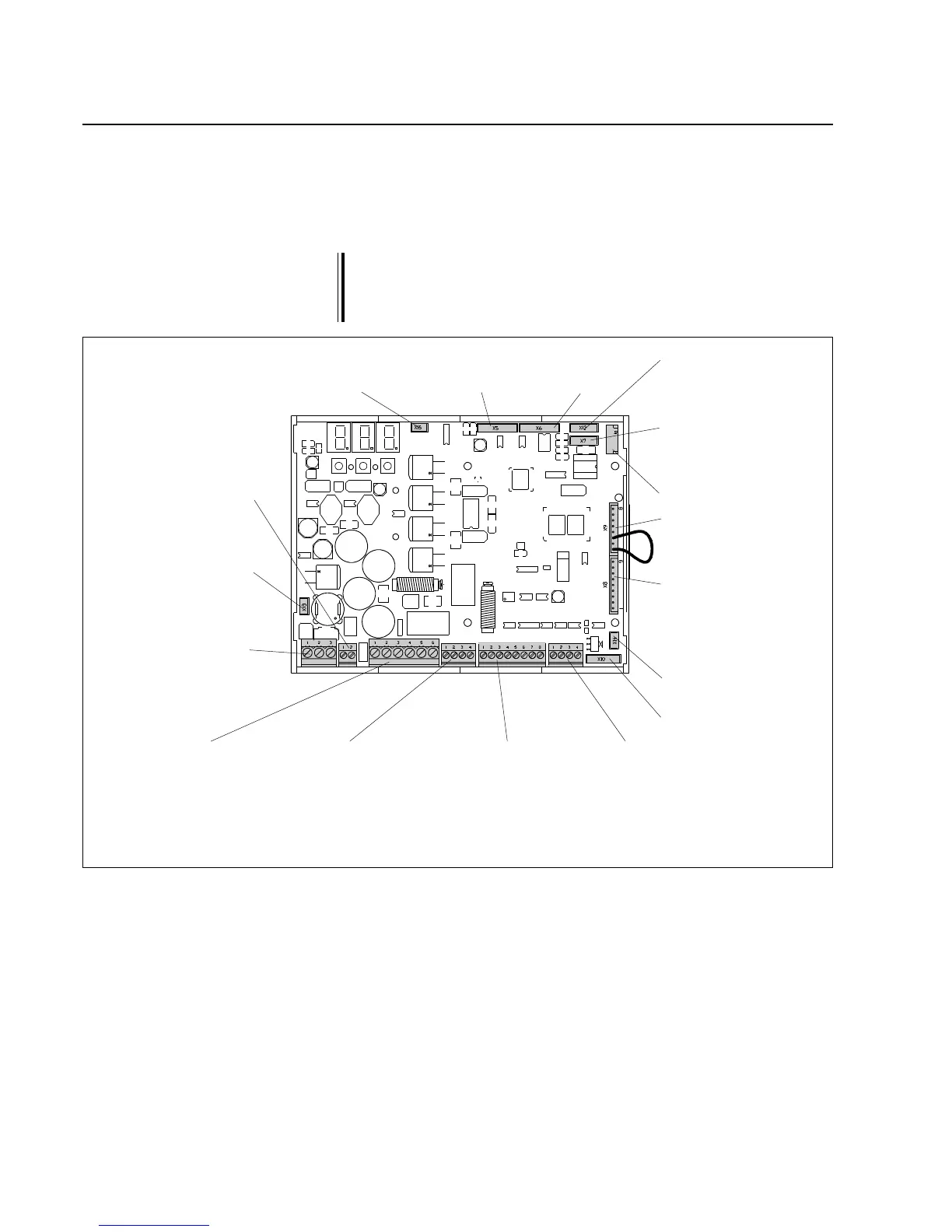

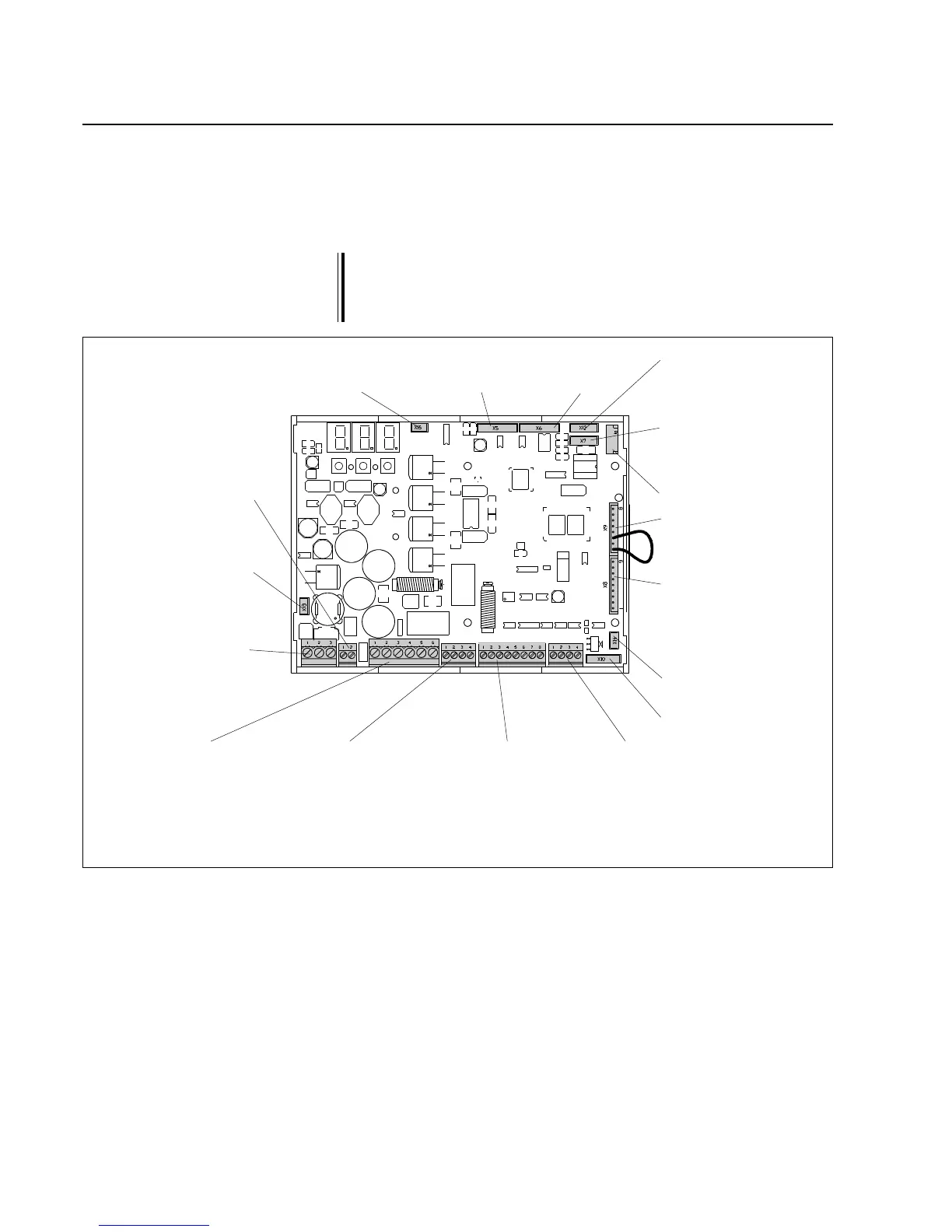

Digital controller RK 4004

RK 40.. terminal assignments

X 9 serial bus

X 8 Analogue card

AK 4002

(only when ana-

logue sensors are

used)

X 14 External configu-

ration adapter

X 10 Optical incre-

mental encoder

X 7 CAN connection

with LED display

for CAN device

connector

X 6 Left

digital

sensor

X 5 Right

digital

sensor

X 12 CAN connection

without LED display

for internal device

networking

X 15 Fan

X 13 Supply voltage

for further E+L

modules

X 2 DC actuator

and incre-

mental en-

coder

X 3 Command sta-

tion for web

offset RE .... or

signal for path-

dependent

oscillation

X 4 Reference

switch, guider

lock and end

position signal

X 20 End switch

X 21 Supply voltage

for further E+L

modules

X 1 Operating volta-

ge

The wiring diagram indicates which connectors are assigned.

The guider lock is intended for on-site requirements where the actua-

tor is to be stopped in its current position. If the guider lock is closed

(make contact) the actuator remains in this position until the contact

is open again.

X 11 SPI bus

4. Installation

➜ Connect electrical leads according to the attached wiring diagram.

➜ Shield and run signal lines away from heavy current-carrying

leads.

The DC actuator motor line must be run separately (separate ca-

ble) from the incremental encoder line.

The connection line between the controller card and DC actuator

may be run in one lead up to a length of 3 m. From a distance of

3 m to 10 m the motor and incremental encoder lines must be

run separately.

Loading...

Loading...