OPERATION INSTRUCTIONS

NOTE: Before using the tool, read the

instruction book carefully.

INTENDED USE

The machine is intended for routing grooves, edges,

profiles and elongated holes as well as for copy

routing in wood, plastic and light building materials,

while resting firmly on the workpiece.

1. INSERTING AND REMOVING THE ROUNTER

BITS

Router Bit Selection

Depending on processing and application, router bits

are available in many different designs and qualities:

Router bits made of high-speed steel (HSS) are

suitable for the machining of soft materials, e. g.

softwood and plastic.

Carbide tipped router bits (HM) are particularly

suitable for hard and abrasive materials, e. g. hard

wood and aluminum.

TCT (Tungsten Carbide Tipped) - for use on hardwood,

chipboard, plastics or aluminium.

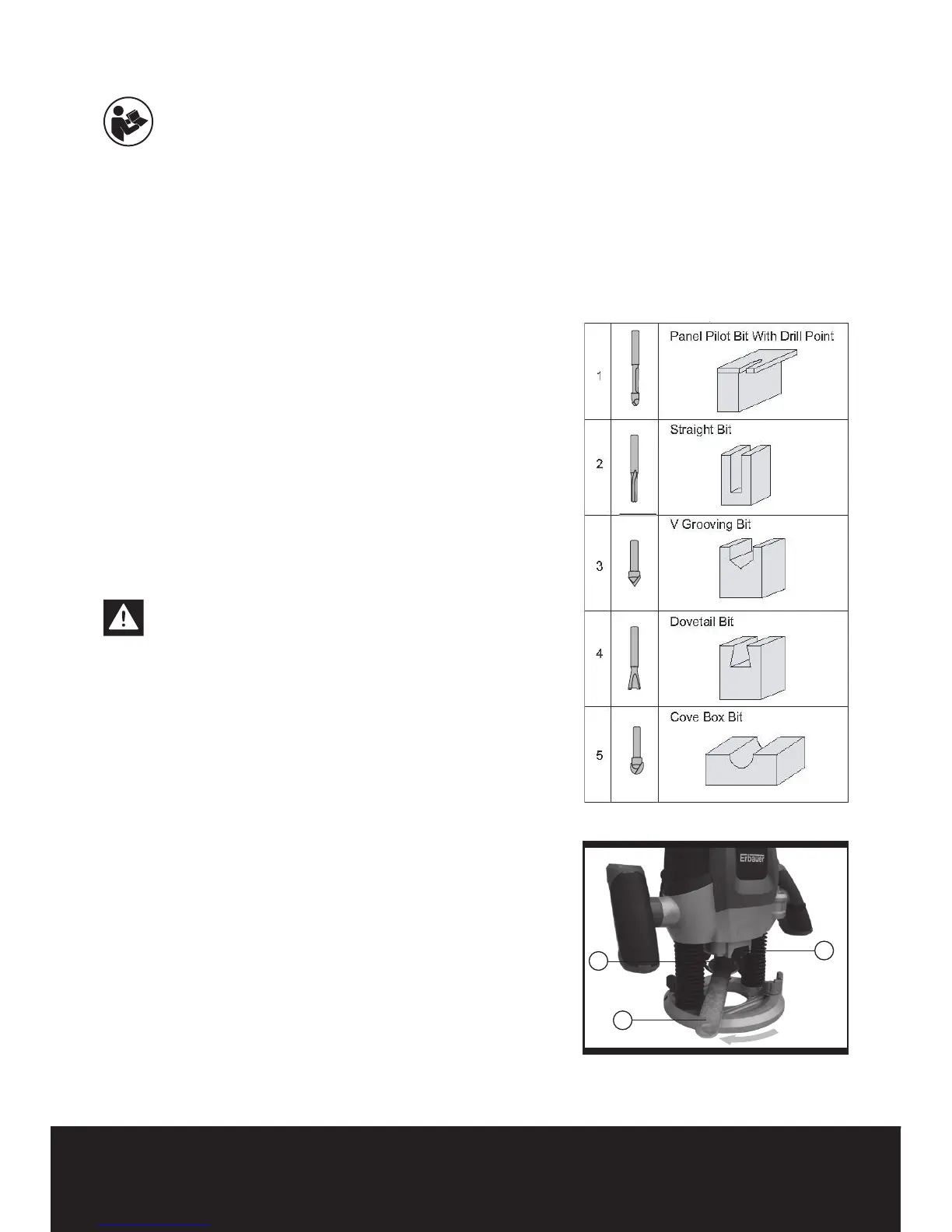

The most commonly used bits are listed below.

Warning: Use only routing tools with an

allowable speed matching at least the

highest no load speed of the machine. The shank

diameter of the router bit must correspond with

the rated diameter of the collet. Never use router

bits with a diameter exceeding the diameter of

the collects.

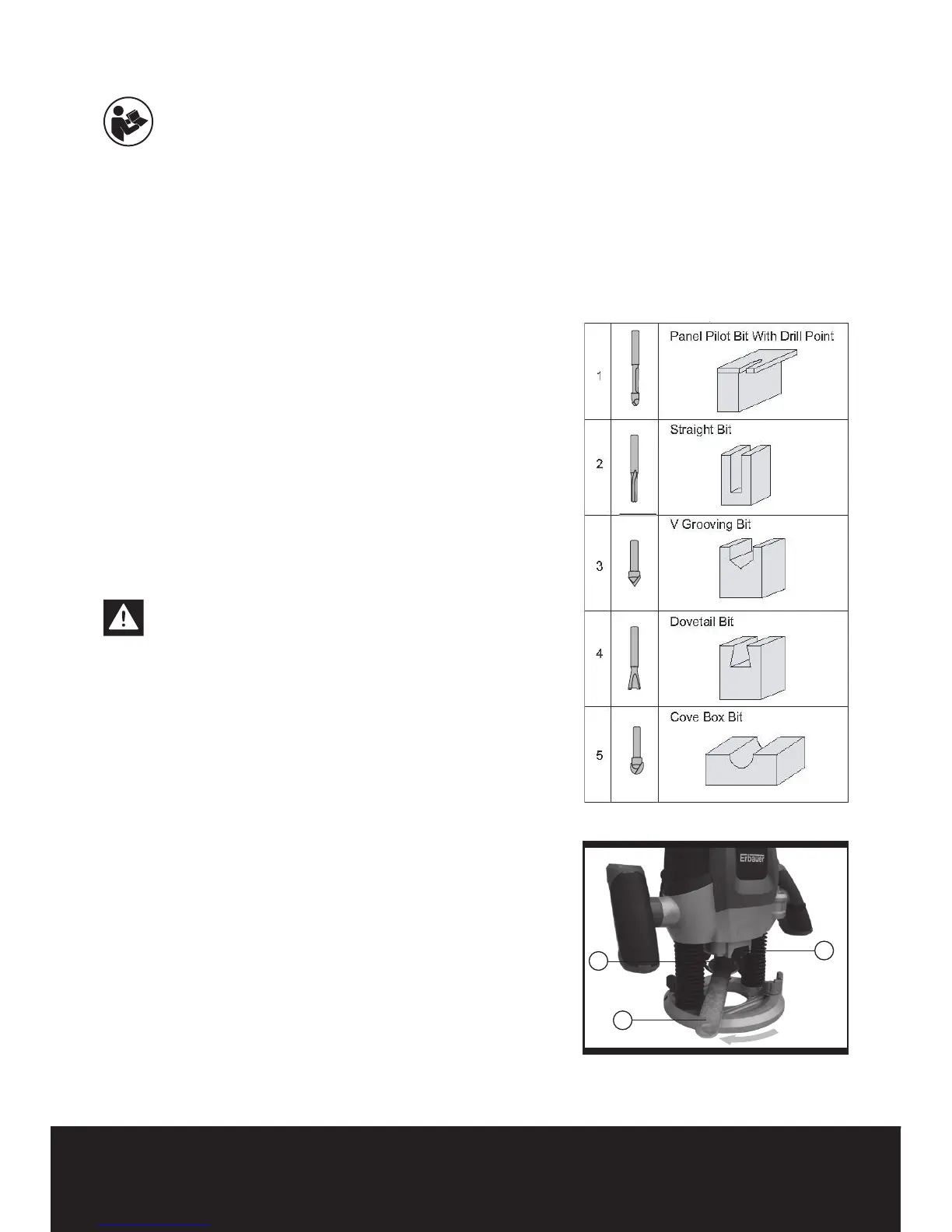

Inserting Router Bits (See Fig 1)

Always disconnect the mains plug when fitting

router bits and accessories. It is recommended

to wear protective gloves when inserting or

replacing router bits.

Press spindle lock button (14) and keep depressed.

If required, turn the spindle by hand until the lock

engages.

Press the spindle lock button only when at a

standstill.

Using the 22 mm spanner (19), loosen the collet nut

(13) a few turns and insert a router bit. The shank of

the router bit must be inserted at least 20 mm (shank

length)or at least as far as the ‘K’ mark on the shank

(where marked).

Fig 1

Loading...

Loading...