side of the router where the locking screws (12) are

located.

• Mark the workpiece at the centre of the desired

circle.

• Loosenthescrewofcentrepin(22),andtintothe

centre hole of the adjustment guide (F), then fasten

the screw to use.

• Place the centrepinagainst themark ofdesired

circle on the workpiece.

• Adjust the position of the rods and router as

necessary to achieve the desired radius of the

circle or arc, then securely tighten wing knobs.

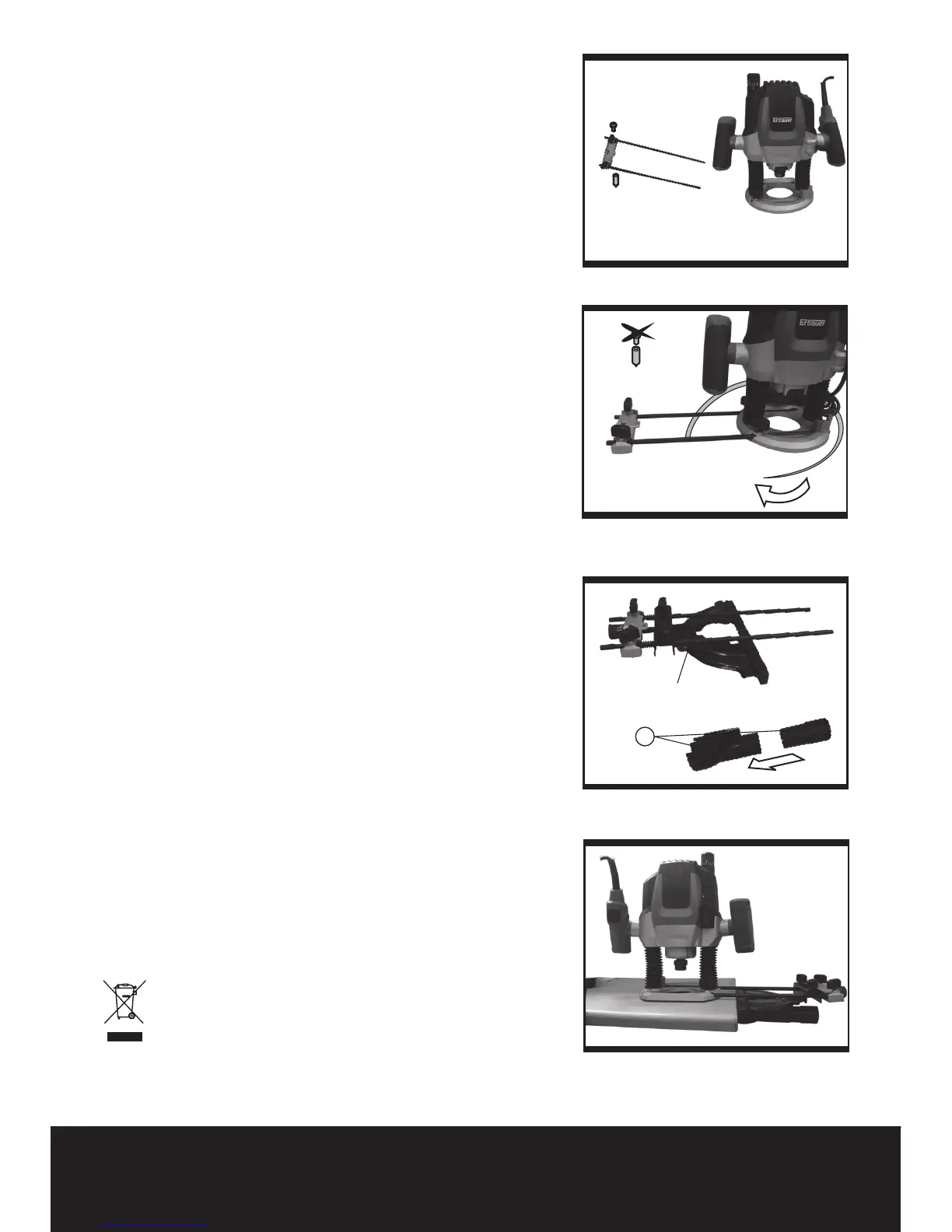

12. USING EXTRACTION ADAPTER FOR

PARALLEL GUIDE (See Fig 12-1, 12-2)

When the machine routing on an inclination surface,

the dust/chip extraction should take place via the

special extraction adapter for the parallel guide (30).

To mount the extraction adapter for the parallel guide,

first insert the tab (a) into place, then engage the front

two tabs into place. And then mount the parallel

guide with the extraction adapter onto the router.

MAINTENANCE

Remove the plug from the socket before carrying out

any adjustment, servicing or maintenance.

Your power tool requires no additional lubrication or

maintenance.

There are no user serviceable parts in your power

tool. Never use water or chemical cleaners to clean

your power tool. Wipe clean with a dry cloth. Always

store your power tool in a dry place. Keep the motor

ventilation slots clean. Keep all working controls free

of dust. Occasionally you may see sparks through the

ventilation slots. This is normal and will not damage

your power tool.

If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed

of with household waste. Please recycle where

facilities exist. Check with your Local Authority

or retailer for recycling advice. For further information

visit www.recycle-more.co.uk

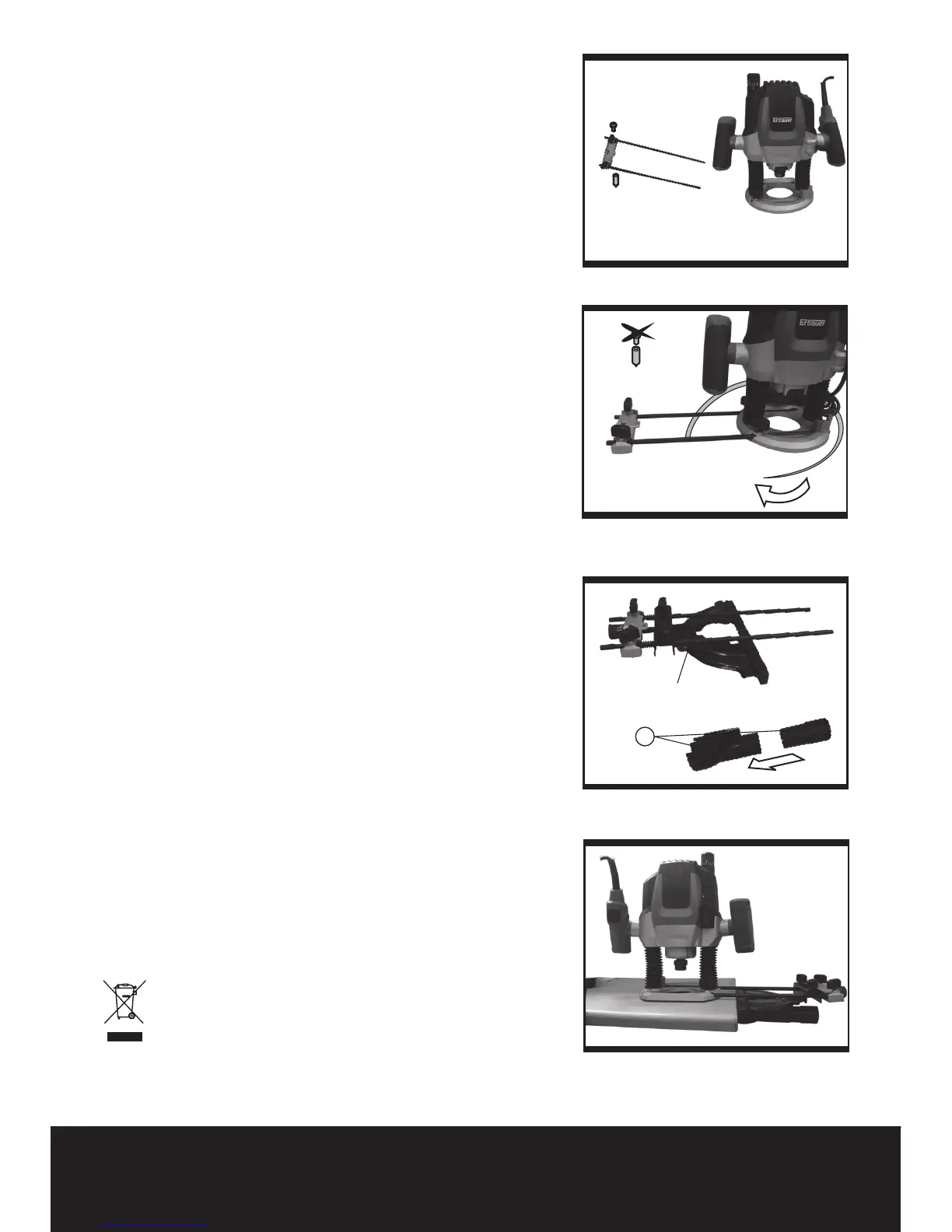

Fig 10

Fig 11

Fig 12-1

Fig 12-2

Loading...

Loading...