step buffer, the cutting process can be divided into

several steps.

Set the required depth-of-cut with the lowest step of

the step buffer. Afterwards, the higher steps can be

used for the last two cuts.

b) Pre-adjustment of varying depth-of-cuts

If several different depth-of-cuts are required for the

machining of a work-piece, these can also be preset

by using the step buffer.

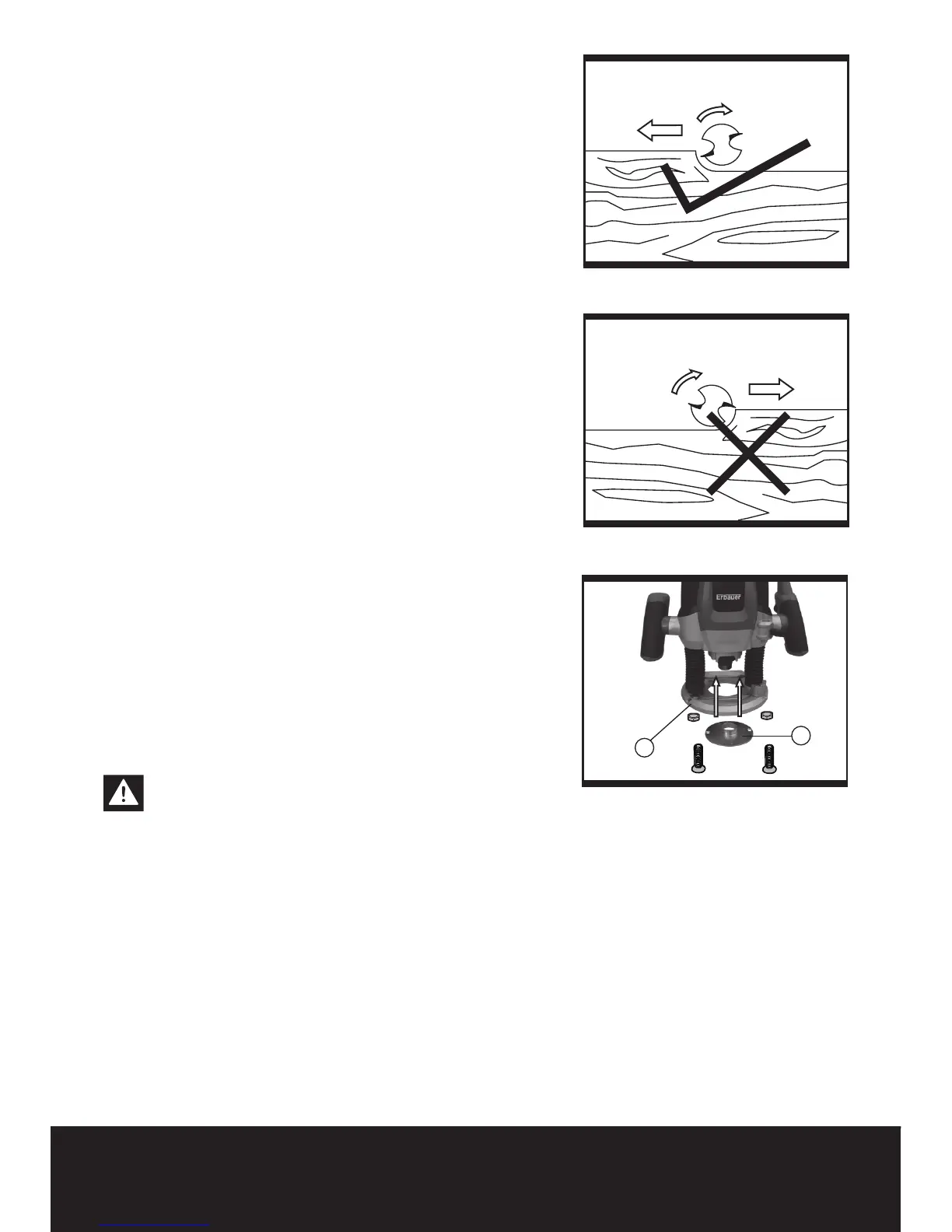

6. DIRECTION OF FEED (See Fig b, c)

The feed motion of the router must ALWAYS be

carried out against the rotation direction of the router

bit (See Fig b).

Do not route in the same direction of rotation as the

router bit, the router can become loose, preventing

control by the user.

7. MAKING A CUT

Note: Before starting work make sure workpiece is

firmly secured.

Place the base plate on the workpiece ensuring that

the bit is not in contact with the material to be cut.

Switch on the router and allow the bit to reach

maximum speed.

Release the clamping lever by turning in clockwise

direction and slowly lower the bit into the workpiece

surface,

keeping the base plate flush and advancing

smoothly until cutting is complete.

Keep the cutting pressure constant, taking care not

to overload the router so that the motor speed slows

excessively.

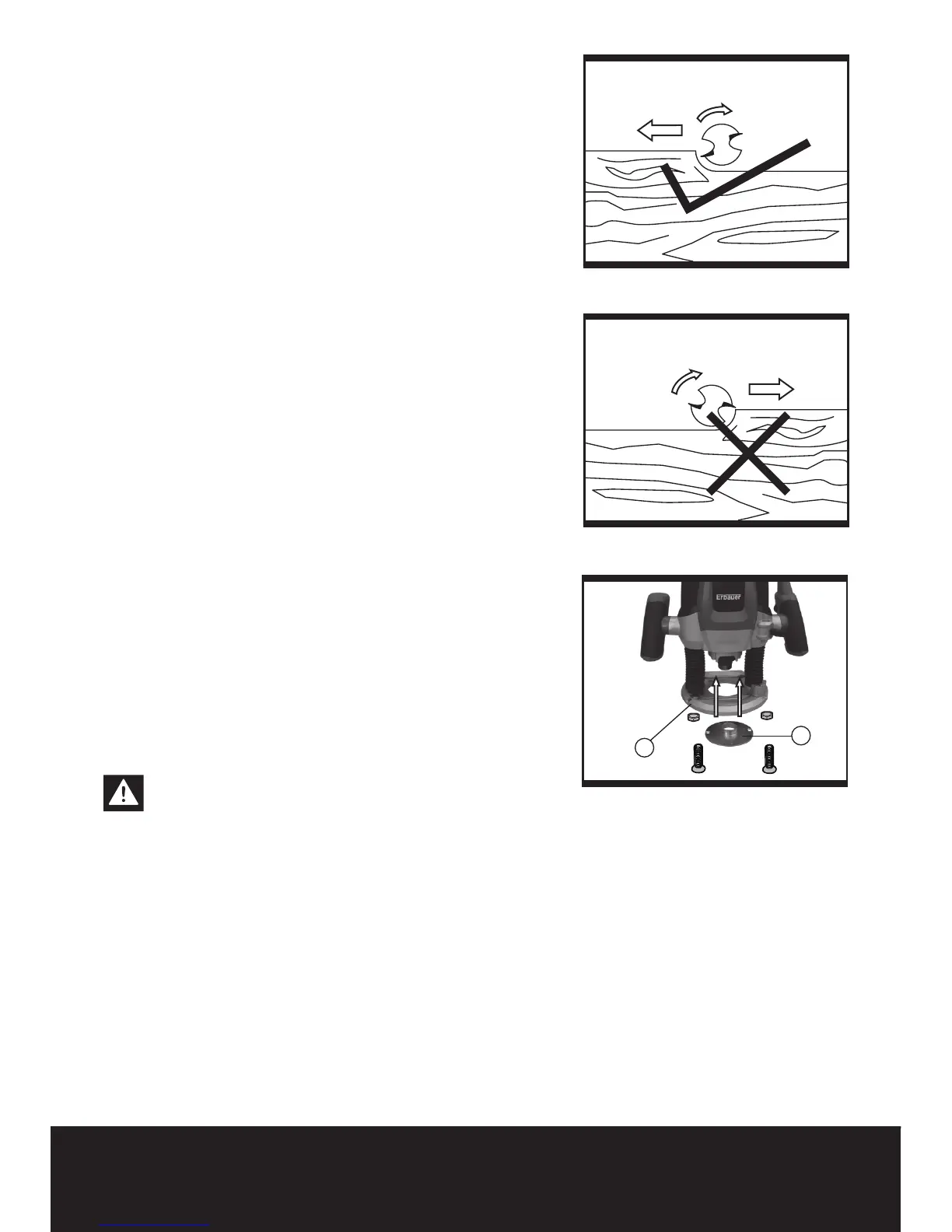

8. ROUTING WITH GUIDE BUSH (See Fig 6)

Warning: Choose a router bit with a smaller

diameter than the inner diameter of the

guide bush.

The guide bush (24) enables template and

pattern routing on work-pieces.

Place the guide bush over the hole in the

centre of the base plate, and align the two through

holes in the bottom of the base plate with the

countersunk holes in the guide bush. Fasten

the guide bush with the nuts and screws

provided.(See Fig 5).

Set the router with guide bush against the

template. Release the clamping lever by turning

in clockwise direction and slowly lower the router

toward the work-piece until the adjusted depth of cut

Loading...

Loading...