-- 3 1 --

dgb3d1ea

5 MAINTENANCE

5.1 General

Stop the drive unit and switch off the power before carrying out any maintenance

work.

1. Inspect the carbon brushes once a month to make sure they have not seized in

their carriers. Carbon brushes normally have a life of 1000--1500 hours,

depending on operating speed. Brushes must be replaced before their length

has been reduced to 12 mm. See also Wear Compoments on page 34.

2. Lubricate the toothed gears, which are nearest to the motor, using ESSO

Beacon grease. Lubricate the worm gear, which is reached through a plug in the

gearbox, using 0.1 l of ESSO Spartan EP 680 oil.

3. Check that the sealing ring between the toothed gears and the worm gears is

undamaged. Replace if necessary and refill the gears with new lubricant.

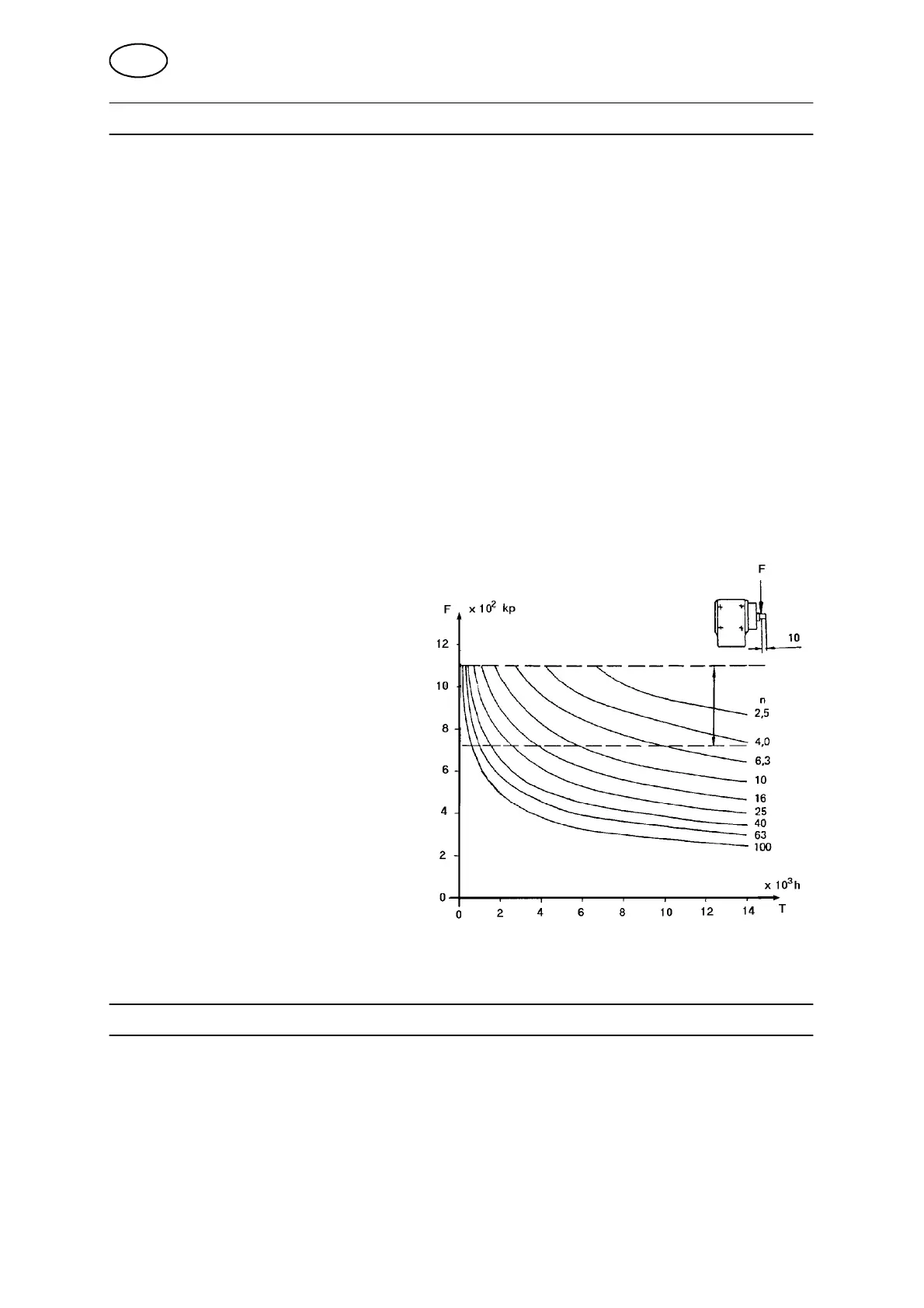

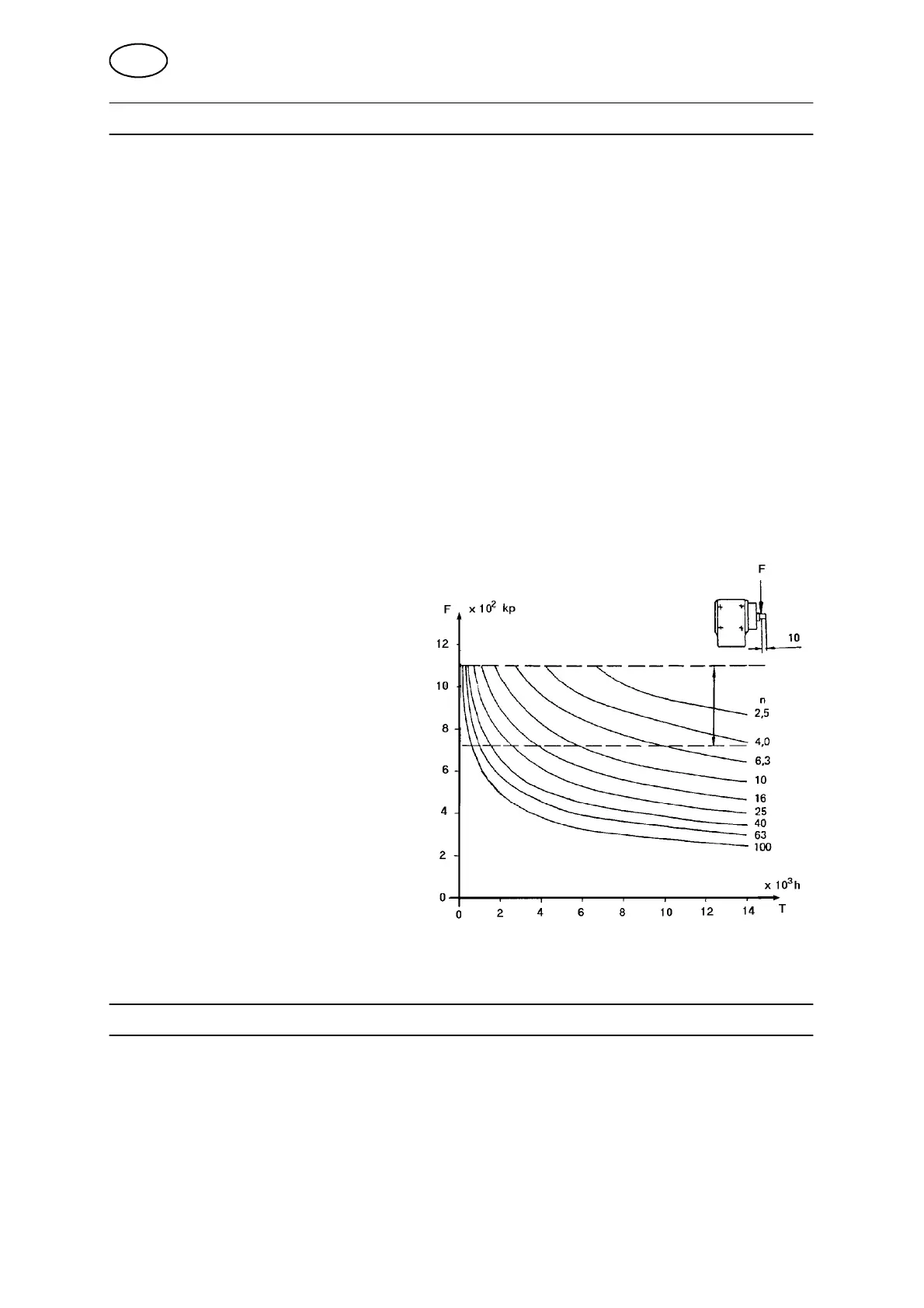

5.2 Ball bearing life

Ball bearing life (T) as a function of load on shaft stub (F).

Calculation applies to bearing SKF 6305.

n = Output drive speed for smooth operation

F = Load on stub shaft

T = Operating hours

6 ORDERING OF SPARE PARTS

Spare parts are ordered through your nearest ESAB representative, see back cover.

When ordering spare parts, please state machine type and number as well as desig-

nation and spare part number as shown in the spare parts list on page 35.

This will simplify dispatch and ensure you get the right part.

GB

Loading...

Loading...