S0740 800 196/E101019/P76

- 58 -

ca41f2calarcv

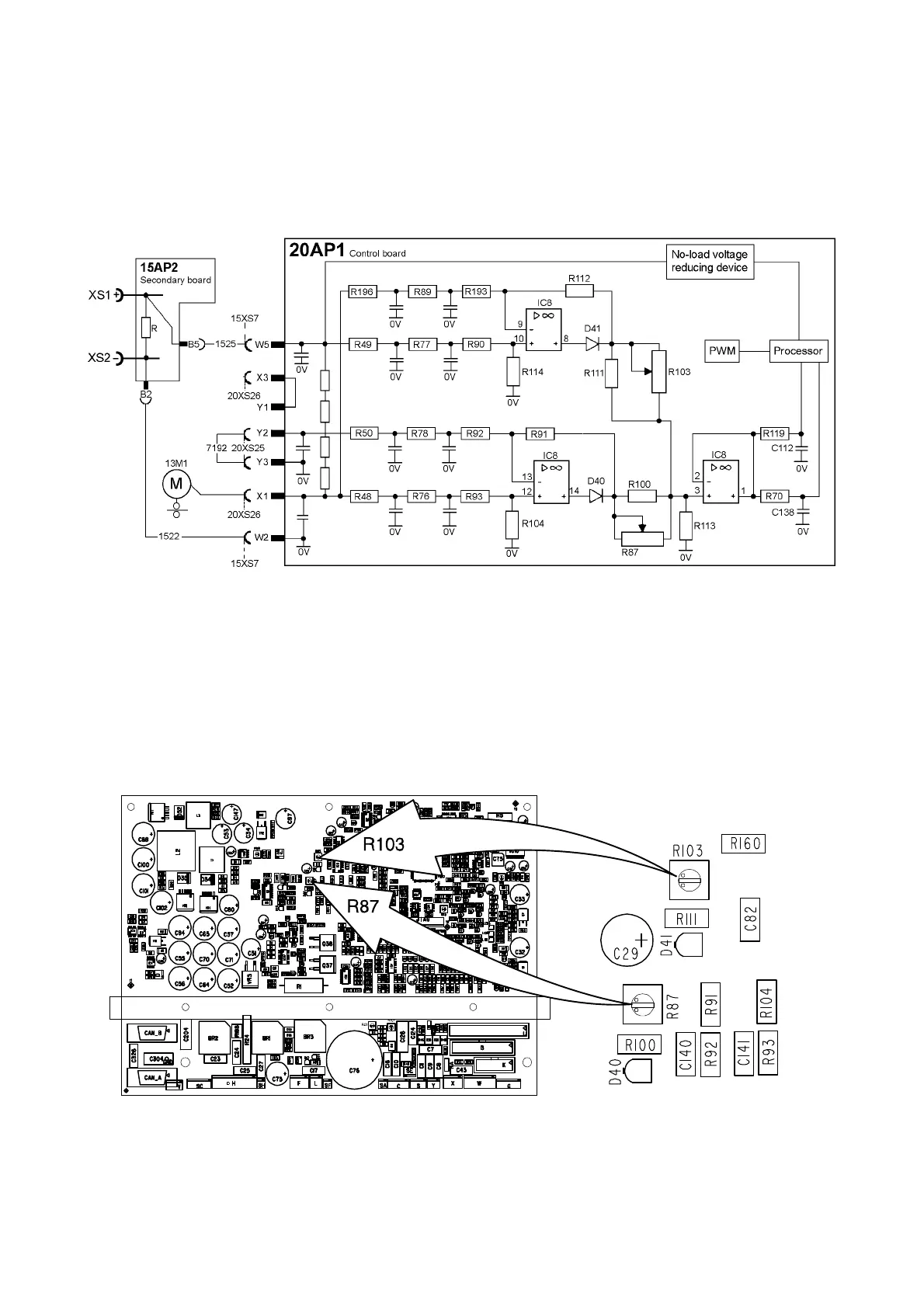

MIG power sources, calibration of the arc voltage feedback

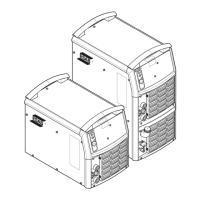

The arc voltage input can be calibrated using trimming potentiometers R87 and R103 on

circuit board 20AP1. The board has been calibrated in the factory: further adjustment

should not normally be necessary.

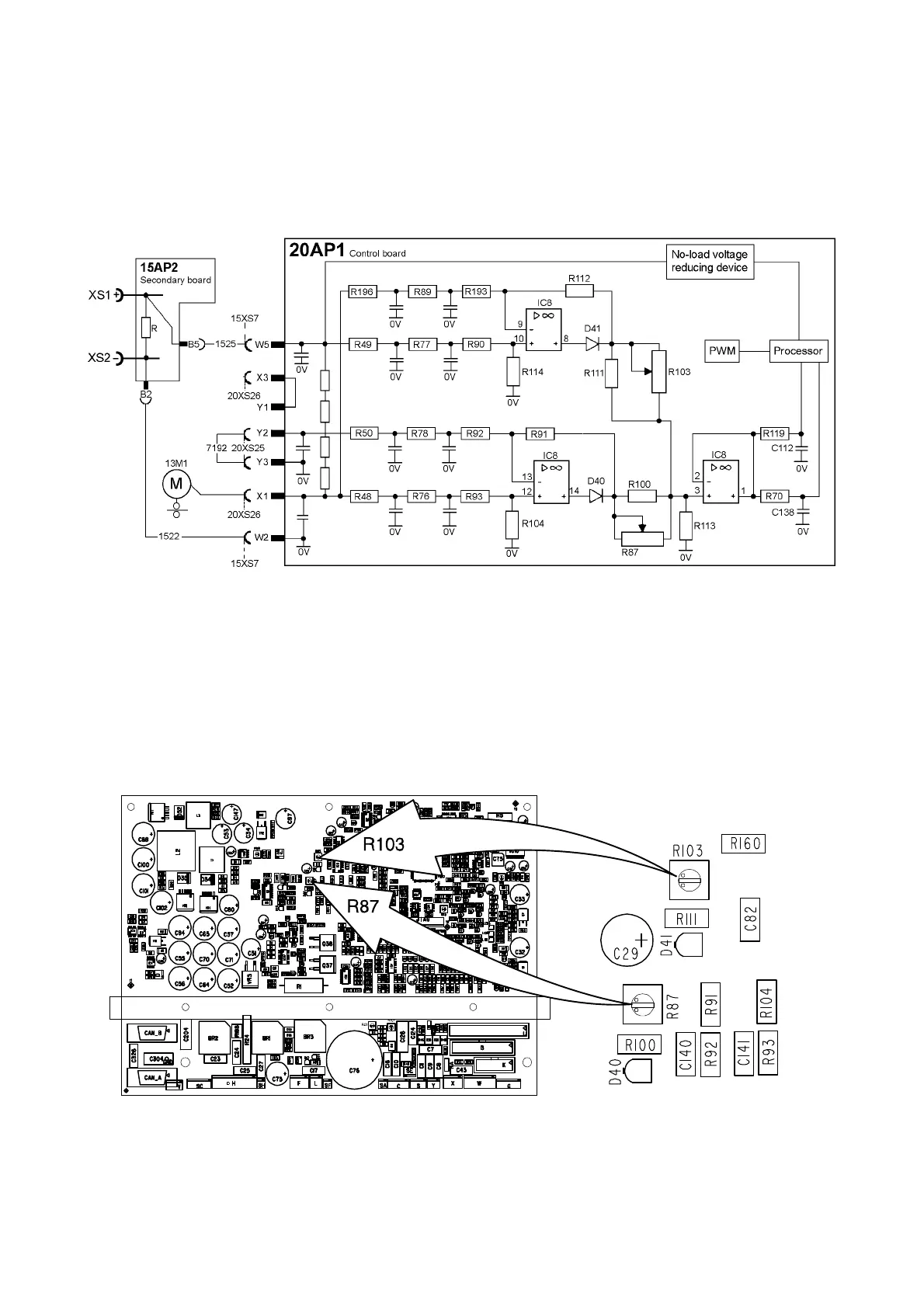

Circuit diagram of the arc voltage input

Check that there is a jumper across connectors Y2 - Y3: see the circuit diagram above.

Connect a wire feed unit to the power source. Connect long welding current cables, to give

an appreciable voltage drop in the cables. Connect a wire to the feed rollers, and connect

an external voltmeter, as shown in the diagrams on next page. Set the power source to MIG

short arc welding mode, and apply a resistive load to give a current of 100 A at 25 - 30 V.

Start the power source from the welding gun trigger contact and adjust the current by

changing the wire feed speed setting. Adjust the voltage by varying the load resistor.

Use an accurately calibrated external voltmeter to measure the output voltage of the

power source.

Positions of potentiometers R87 and R103 on circuit board 20AP1

Loading...

Loading...