12

Kongsberg XN / iPC 2.0

90

Maintain bit clamping

Un-proper bit clamping may cause the bit to

slip in the chuck and damage the Table Top.

1. Keep the bit shaft clean.

2. Avoid greasy fingers.

3. Clean the bit shaft with acetone if

necessary, but use only dry cotton tips on

the chuck.

4. Maintain Pressurized Air supply of 7 bar.

5. Follow procedures strictly: Chuck Change

and Cleaning on page 96.

Long term storage

More than 4 weeks storage of a spindle or a

MultiCUT/MultiCUT-HP requires:

1. Turn the spindle by hand about 20 turn

every 4 weeks.

2. Spindle must be stored horizontally.

Consider having a replacement spindle

If MultiCUT-HP is used in regular production,

it is recommended to have a Replacement

Spindle.

The service interval will depend on the type of

operation, and is difficult to predict.

Indication of worn bearings may be increasing

noise, increasing vibrations or decreasing

surface finish.

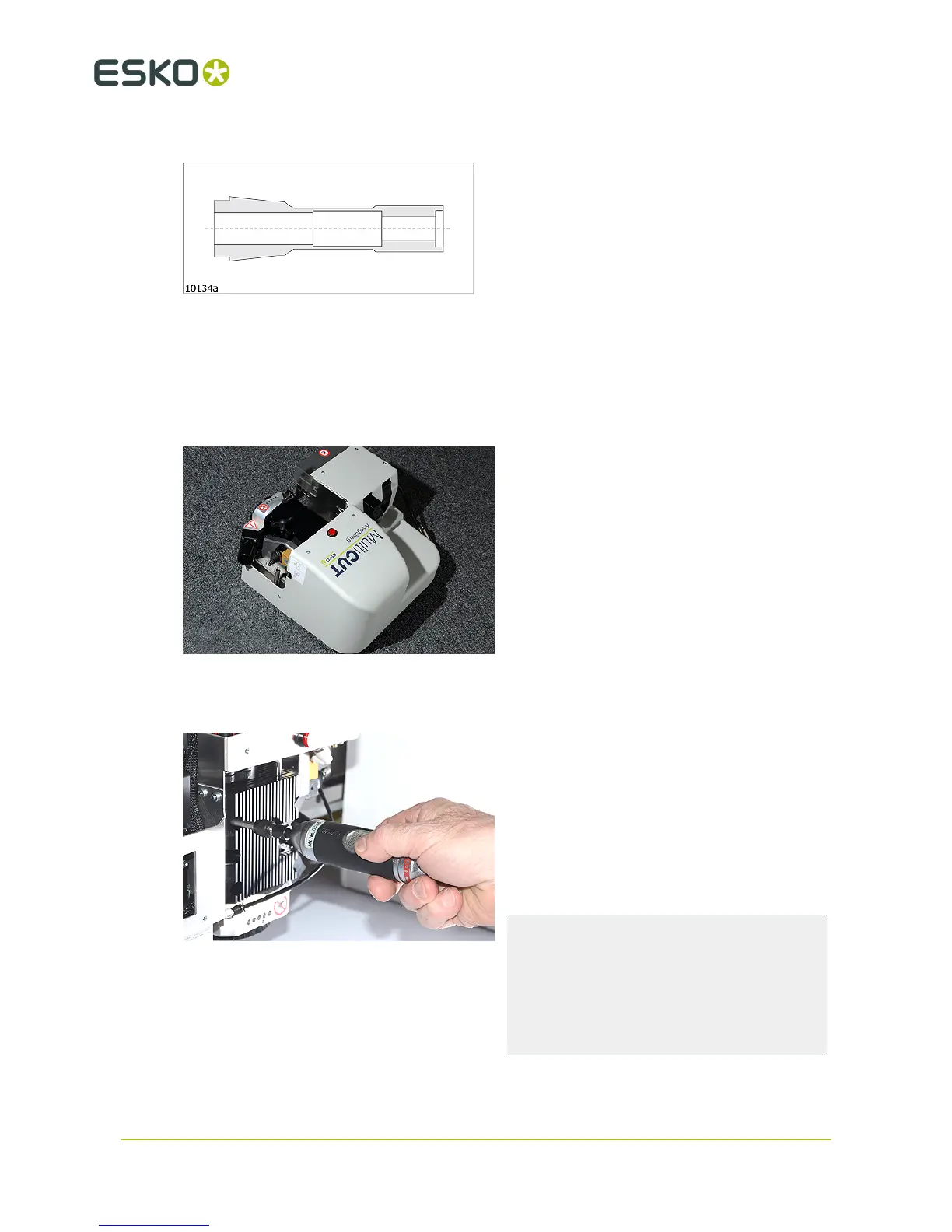

Note: When replacing a Spindle, torque the

motor clamp to 5 Nm, 44 lbf-in using a Torque

Wrench.

This is a low torque for that screw size.

Also check by hand that the Spindle rotates

smooth without any resistance.

Loading...

Loading...