24

Set the Wheel Synchronicity of Exhaust Chuffs

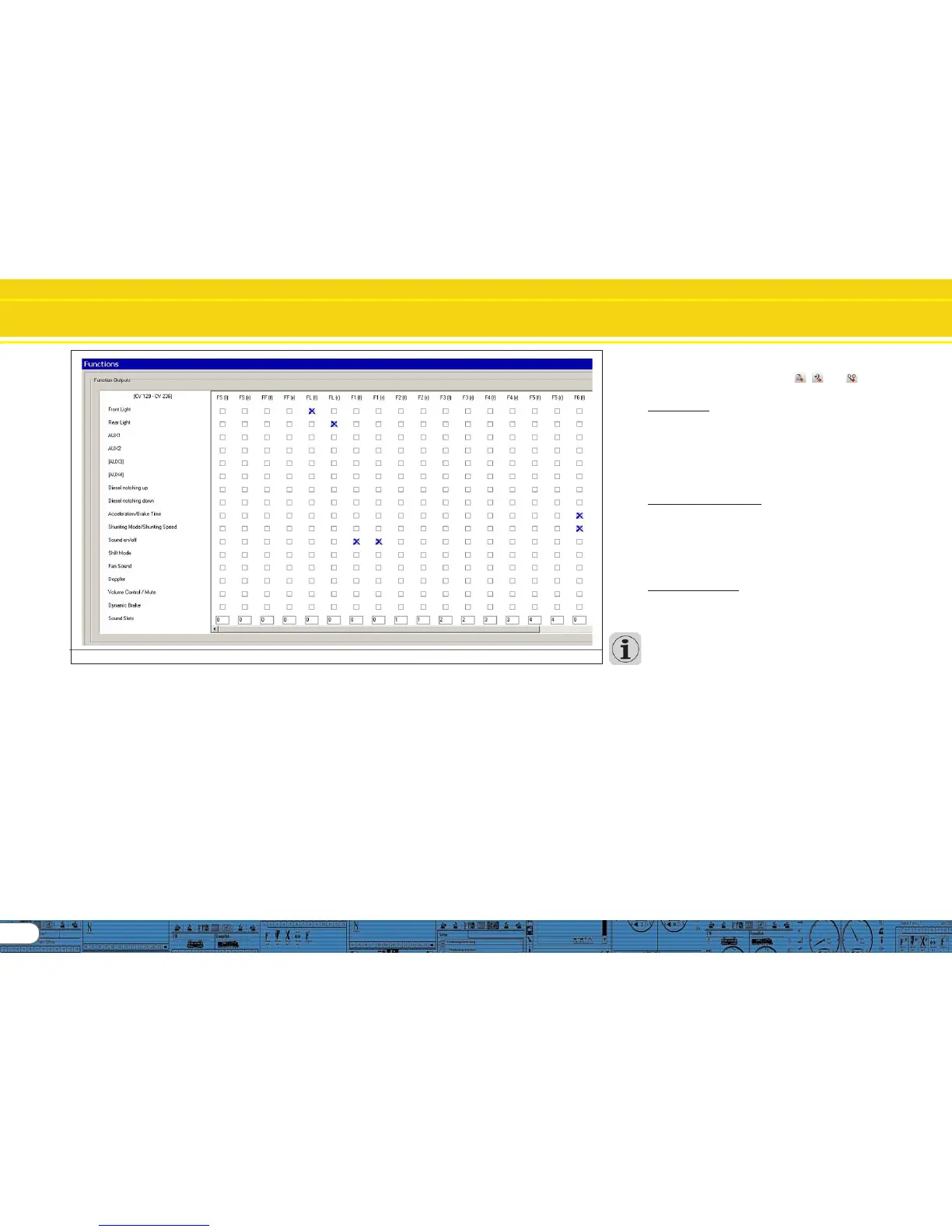

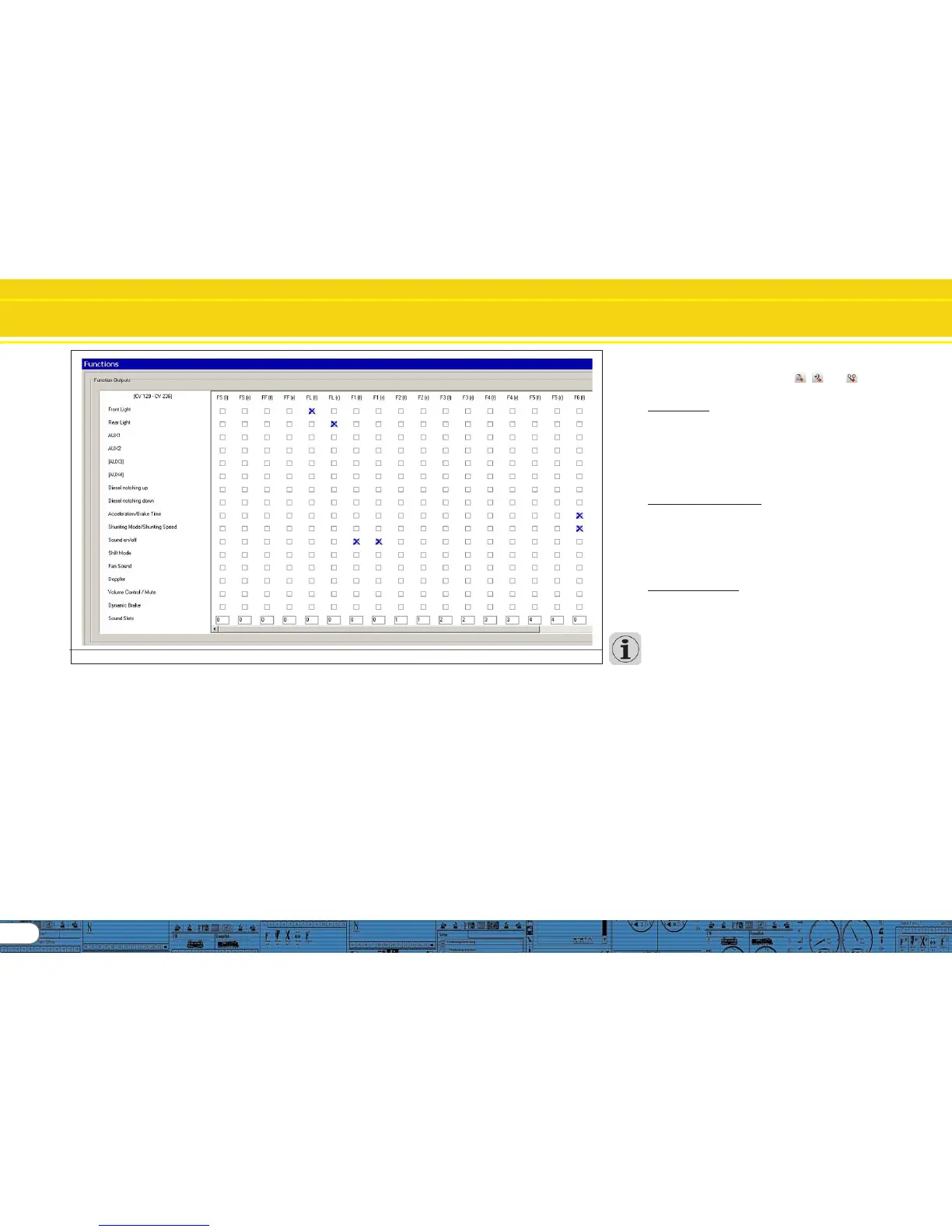

Fig.37.: Default Allocation of Function Buttons

12.2.5. Set the wheel synchronicity of exhaust chuffs12.2.5. Set the wheel synchronicity of exhaust chuffs

12.2.5. Set the wheel synchronicity of exhaust chuffs12.2.5. Set the wheel synchronicity of exhaust chuffs

12.2.5. Set the wheel synchronicity of exhaust chuffs

After you have imported all sounds into the correct sound slots

and have entered the first driving parameters it is time to look

at a special feature for steam locomotives without external

wheel sensor, namely setting the exhaust chuffs according to

the revs of the drivers. You can set the necessary parameters

with the option „Type of Sound“ 12.2.5. Radsynchronität der

Dampfstöße einstellen(CV57 and 58). First make sure that the

correct number of cylinders has been entered in the menu

„Extended Settings“ and that you have imported the

appropriate chuff sounds (also refer to 9.2.4.). Furthermore

the mid speed and the maximum speed (CV5 and 6) must have

been set since this would influence the synchronicity if it was

changed later on.

• Place the locomotive onto the programming track or a test

bed.

• Run the locomotive on speed step 1 with the virtual cab or your

digital system.

• Observe one wheel and its movement and count the number

of exhaust chuffs that are played during one turn of the wheel.

• If there are too many chuffs during one turn the time span is

too small. Increase the value in CV 57 until the desired

synchronicity is achieved.

• If there are not enough chuffs during one turn the time span is

too big. Reduce the value in CV 57 until the desired synchronicity

is achieved.

• Now switch to speed step 2.

• Observe one wheel and its movement and count the number

exhaust chuffs that are played during one turn of the wheel.

• If there are too many chuffs during one turn the time span is

too small. Increase the value in CV 58 until the desired

synchronicity is achieved.

• If there are not enough chuffs during one turn the time span is

too big. Reduce the value in CV 57 until the desired synchronicity

is achieved.

Since CV 57 and 58 influence each other you must check the

synchronicity of speed steps 1 and 2 repeatedly. Thus you get

closer and closer to the desired synchronicity in several steps.

12.2.6. Fine tuning12.2.6. Fine tuning

12.2.6. Fine tuning12.2.6. Fine tuning

12.2.6. Fine tuning

Save the project and write it onto your decoder with the aid of

your LokProgrammer. Use the buttons , and . Listen

to the sounds during normal operation and fine tune them

further if necessary.

Sound volumes: You can adjust the volume of the individual

sound settings in the sound slots separately or with the group

volume controllers 1 to 312.2.6. Feinabstimmung.

In our example you can adjust all driving sounds with controller

3 (=CV123), the whistle with controller 1 (=CV121) and the bell

with controller 2 (=CV122); all other sounds are adjusted

individually.

You can adjust the overall volume in the menu „Sound Set-

tings“ or with CV 63.

Minimal time between chuffs: should the exhaust chuffs sound

too hard a high speeds you can set a time limit with the option

„Minimal time between exhaust chuffs“. Then the chuffs will

not be played any closer together than that time limit. Once

the locomotive reaches the speed at which the current time

between chuffs corresponds with the minimal time between

chuffs the time remains constant – even at higher speeds. This

method is recommended for high speeds of the locomotive

since the synchronicity cannot be observed anyway.

Brake sound threshold: If the brake sound starts too late or

(due to the large file size) it is not played at all simply increase

the value for the brake sound threshold. The higher the value,

the sooner the brake sound starts playing and therefore has

more time to be played completely (also refer to 8.5.5.).

In the following chapters many processes that you already

know are repeated from the creation of the steam sound

project. Therefore we only describe the settings that are diffe-

rent in the following chapter.

12.3. Diesel-electric locomotive12.3. Diesel-electric locomotive

12.3. Diesel-electric locomotive12.3. Diesel-electric locomotive

12.3. Diesel-electric locomotive

12.3.1. 12.3.1.

12.3.1. 12.3.1.

12.3.1.

Generate new fileGenerate new file

Generate new fileGenerate new file

Generate new file

Proceed as in 12.2.1..

12.3.2. Settings12.3.2. Settings

12.3.2. Settings12.3.2. Settings

12.3.2. Settings

Proceed as in 12.3.2.., but select „Diesel-electric“ as type of

locomotive. Enter the value „1“ for „Time between Throttle

Notches“. Then the decoder does not divide the sound

automatically in to throttle notches; this is done later with the

different sound files for different throttle notches.

Also set the following under „Address“: Click onto the squares

„FL (f)“ and „FL(r)“ in „Function outputs in consists“. If

locomotives are run in consist, then the lights can be controlled

in both locomotives simultaneously.

Should there be only one driving sound file (d1.wav) it is

recommended to set a higher value for „Time between throttle

notches“. This results in the modulation of sound with different

pitch levels.

Loading...

Loading...