ENGLISH

5

� Range of values:

• pH:

0÷14

• Redox: -1000 ÷ +1400 mV

• PPM: 0÷2, 0÷10, 0÷20, 0÷200 ppm

• Temperature 0÷100 °C (PT100)

Oper at in g pr in ciple of p er is ta ltic p um ps

By peristalsis we mean the propulsive motion of automatic contractions inside a channel or pipe, from whence the term peristaltic

action. Through the mechanical simulation of biological peristalsis, rollers compress the walls of a pipe forming a seal during their

movement, then the compressed part of the pipe goes back to its original shape thus suctioning uid by means of the negative pressure

created. The fluid follows the roller until the pipe is no longer compressed. At this point, a second roller is already compressing the pipe

to avoid a backow, pushing the initial dosage of uid out of the pump and repeating the suction action. Rollers mounted on special

rotors allow the pump to run continuously thanks to their inlet/outlet action.

Oper at in g pr incip le of e le ctrom ag ne ti c p um ps

The metering pump operates by means of a PTFE (Teflon®) diaphragm mounted on the piston of an electromagnet. When the

piston of the electromagnet is attracted, it creates pressure on the pump body thus ejecting liquid from the supply valve. When the

electric pulse is nished, a spring brings the piston back to its initial position owing liquid through the suction valve. The pump needs

no lubrication and practically no maintenance thanks to its easy use. The materials used to build the pump make it t for dispensing

chemically aggressive liquids. The metering pump was designed for ow rates from 2 to 5 l/h and pressures from 5 to 6 bar according

to the model.

Main fea tu re s

� Device manufactured according to standards

� Chassis made of: Polypropylene

� Designed for tting level probe

� Standard electric power supply (uctuations of a maximum ±10% are allowed): 230 V a.c. 50/60 Hz single phase.

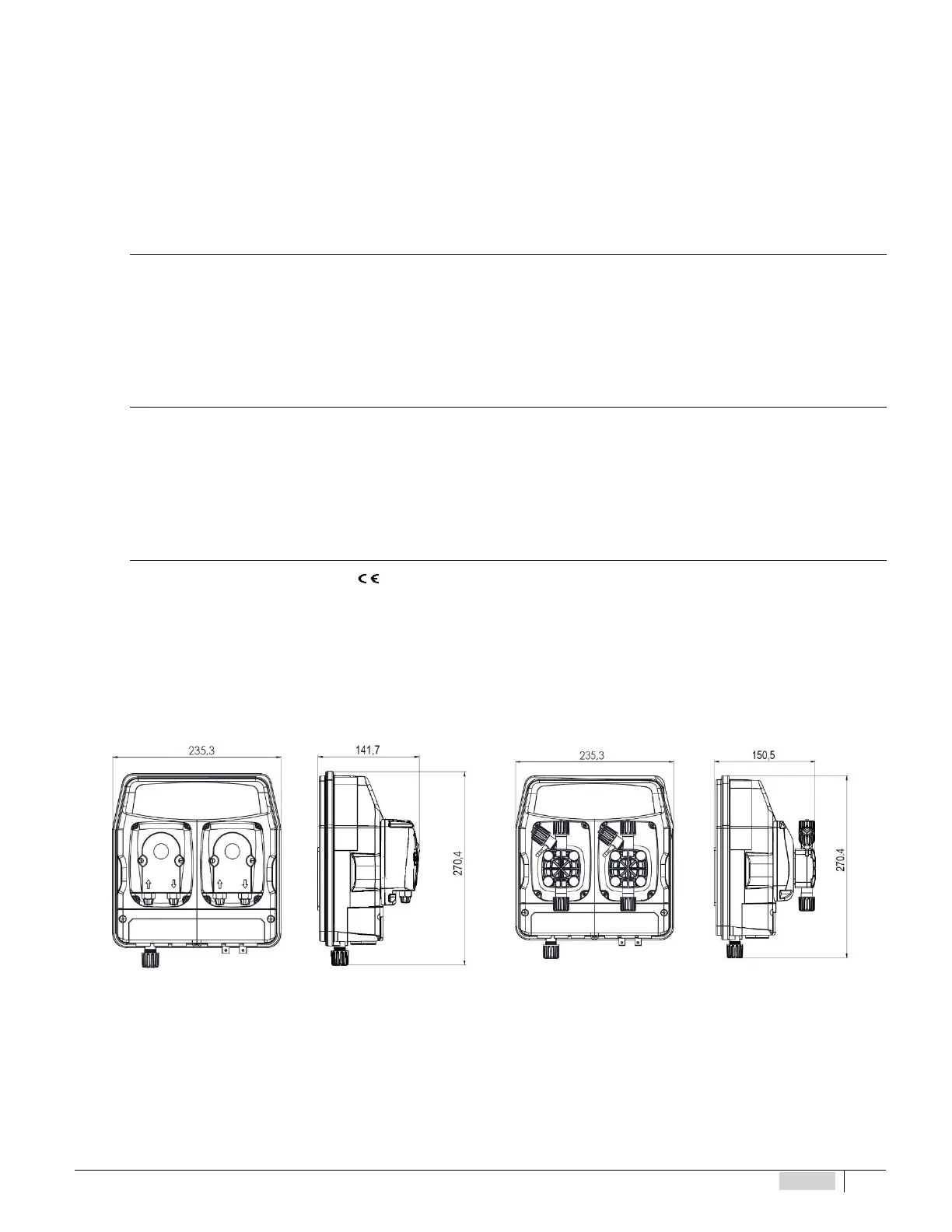

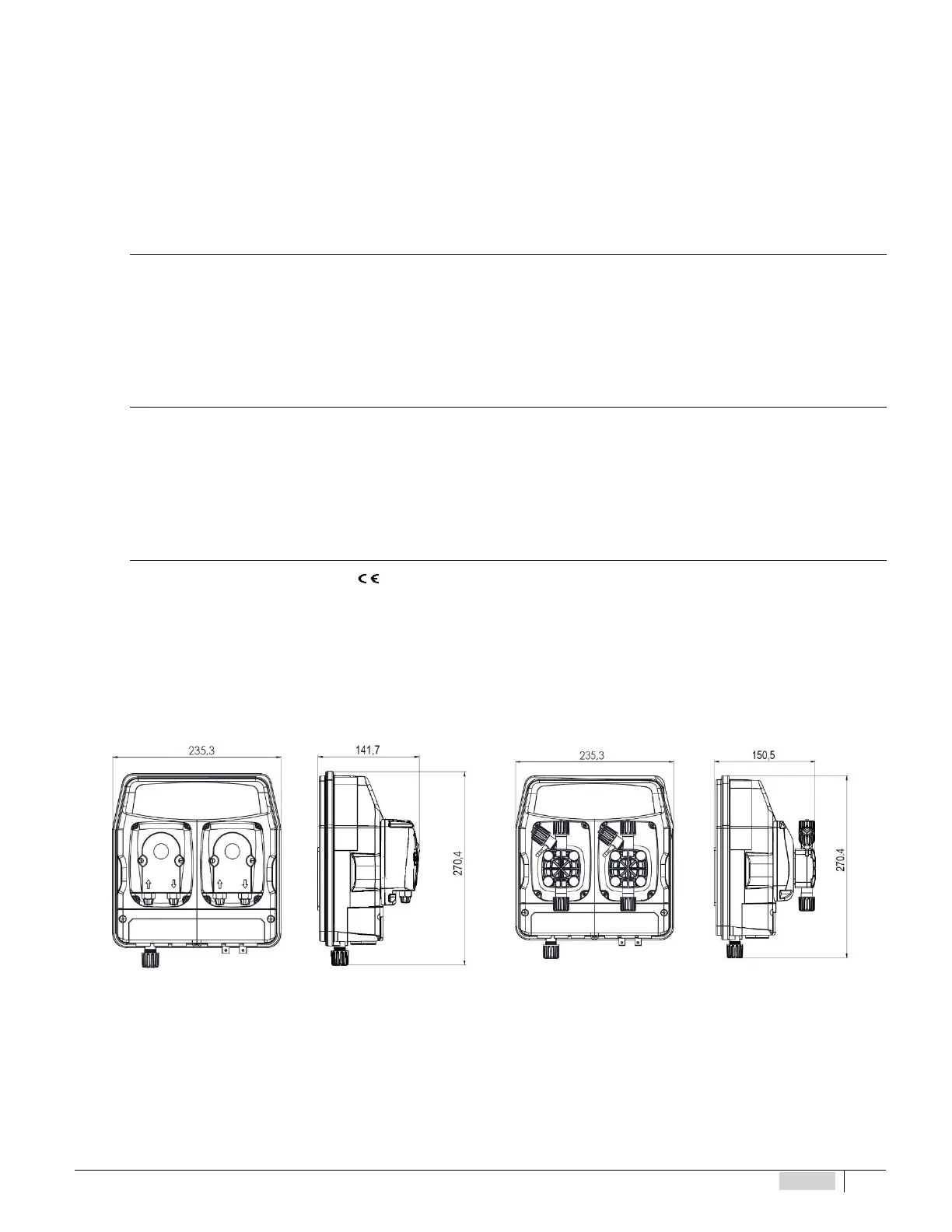

Fig. 1 – Views and dimensions – peristaltic version Fig. 2 – Views and dimensions – electromagnetic version

Loading...

Loading...