Installation and Operation manual ETHOS 36C and ETHOS 54C –1511/05-issue1

Page 12

4 ASSEMBLY INSTRUCTIONS FOR ELECTRICIAN

4.1 Mains connection

The boiler requires an earthed 230 volt 50 Hz single phase supply and must be connected in accordance with all

current regulations and requirements. A permanent supply to the boiler is needed at all times to the boiler, which

should be protected by a maximum 3 Amp double-poled isolator with at least 3mm of contact separation on both

poles.

The single phase cable colour coding should be wired correctly, although the boiler is not polarity sensitive

All control switching is volt free.

ATTENTION!

AT NO TIME SHOULD 230 VOLT BE USED TO SWITCH THE BOILER.

4.2 Terminal block connections

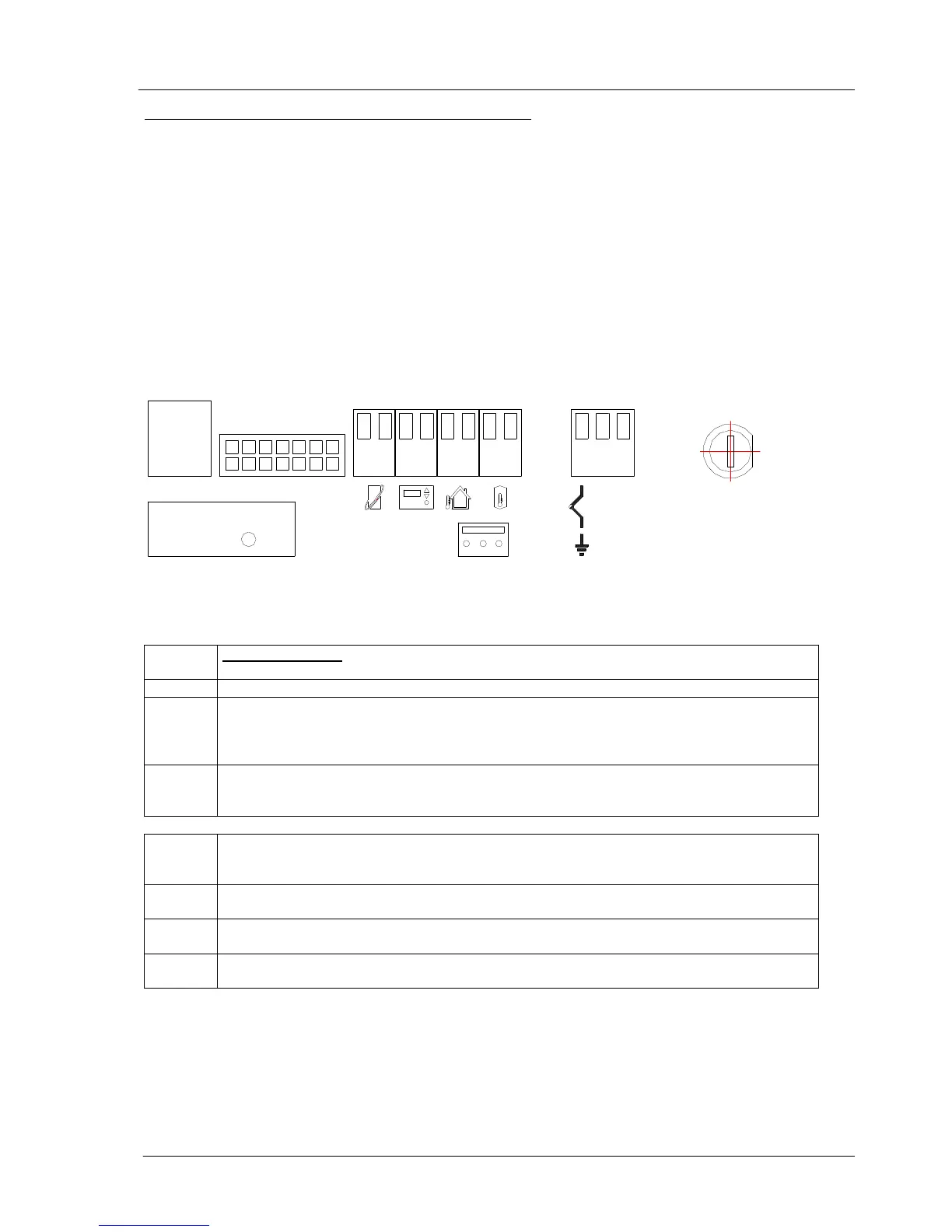

The following parts can be connected to the terminal block, see illustration

PC COM PC communication. The manufacturer can use this connection for reading-out or modifying data or

settings by using a PC and connecting cable.

1-2 OpenTherm® room thermostat / time clock. Can be used to fully modulate the boiler.

3-4. On/off room thermostat / time clock. For connecting clock or conventional room thermostats. The

heat acceleration element of the on/off thermostat must be set at 0.12A; the max. permissible

resistance of the room thermostat circuit should not exceed 10 ohm.

Attention! Do not connect an OpenTherm® room thermostat to this terminal.

5-6. Outside temperature sensor. If an OpenTherm® thermostat with weather dependent control is

used, the outside temperature sensor must be connected to terminals 5 and 6. The OpenTherm®

thermostat contains the settings for weather dependent control.

7-8 External DHW cylinder. The external water heater can be connected to the boiler with a sensor

(NTC) or thermostat; if a sensor is used, the boiler display can show the water heater temperature.

Only applicable for Ethos …SD boilers

PE. N. L Power supply connection 230V. Connection for earthed cable.

PE= earth N= Neutral L= phase 230V 50Hz

CODE

KEY

Code key. A code key is a small PCB which contains the settings per boiler type. When the burner

control unit is replaced, the code key must be installed in the new burner control unit.

ALARM

External failures. This connection can be used for showing external messages by using a relay on

terminals 1 and 3. A LED can be connected to terminals 2 and 3.

CODE KEY

PC

COM

ALARM

1 2

3

4

5 6

7

8

N L

PE N L

FUSE 2AT

Figure 6 Electric terminals

Table 4 Explanation of electrical connections

Loading...

Loading...