ADDITIONAL SAFETY INSTRUCTIONS FOR TABLE SAWS

• Wear a dust mask. Exposure to dust particles can be harmful to

your health and make it dicult to breath. Use a dust extraction

system and wear a suitable protective mask.

• Do not use any abrasive wheels.

• Use only saw blades that comply with the characteristics

specied in this manual.

• Use only saw blade diameter(s) in accordance with the

markings.

• Use only saw blades with a speed marking that is higher than

or equal to the speed marked on the tool.

• Avoid heating the blade tips. Avoid overheating or melting

the materials. When cutting plastic, let the tool do the work. Do

not force the tool or cut too slowly which could result in melting

the plastic.

• Use only saw blades recommended by the manufacturer,

which conform to EN 847-1, if intended for wood and

analogous materials.

RESIDUAL RISKS

Even with application of safety standards and using the tool as

prescribed, certain residual risks can remain:

• Risk of personal injury due to prolonged use.

• Risk of injury caused by dust.

• Risk of injury caused by flying objects.

• Risk of burns due to accessories becoming hot.

• Risk of electric shock due to cutting through electric cables.

When cutting through floors, ceilings of walls ensure there are no

hidden cables or water pipes.

CLEANING AND MAINTENANCE

WARNING: Disconnect the tool from the power source before

any adjustments, cleaning, or maintenance is carried out.

• Use compressed air to blow dirt out of the main housing air

vents and the blade guard. Wear approved eye protection and

a dust mask.

• Use a cloth dampened with water to clean the other areas of

the tool. Never use solvent based or harsh chemicals of any type

as this may weaken, damage or destroy plastic components.

• Do not attempt to modify the tool or accessories in any way.

• When servicing only use Evolution original parts and carried

out by a qualified person.

•

NOISE WARNING

WARNING: The noise emissions during actual use of the

power tool can dier from the declared values depending on the

ways in which the tool is used especially what kind of workpiece

is processed.

WARNING: The need to identify safety measures to protect

the operator that are based on an estimation of exposure in

the actual conditions of use (taking account of all parts of the

operating cycle such as the times when the tool is switched o

and when it is running idle in addition to the trigger time).

The declared noise emission value(s) have been measured in

accordance with a standard test method and may be used for

comparing one tool with another. The declared noise emission value(s)

may also be used in a preliminary assessment of exposure.

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed

of with household waste. Please recycle where

facilities exist. Check with your Local Authority

or retailer for recycling advice.

PRODUCT OVERVIEW KEY

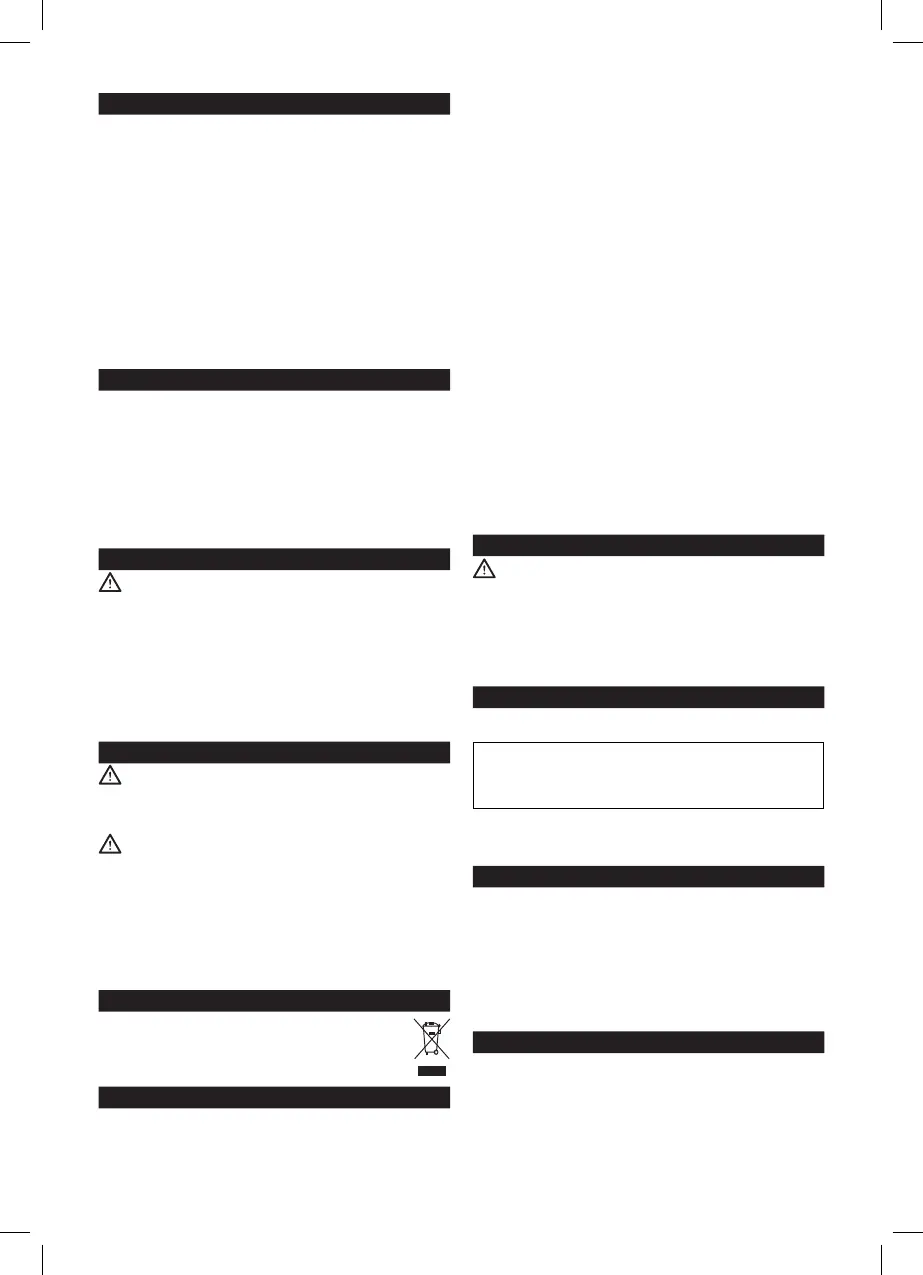

MACHINE OVERVIEW

A. Sliding mitre fence

B. Hold down clamp*

C. Blade guard

D. Riving knife

E. Rack and pinion fence

F. Outfeed support*

G. Rear dust extraction port

H. Table extension locking lever

I. Stand**

J. Stand latch**

K. Sliding table top

L. Extending rails

M. Micro-adjusting dial

N. Bevel locking lever

O. ON/OFF switch

P. Bevel / height adjusting dial

Q. Push stick

R. Spanner x 2

S. Dual hex key

T. Blade

U. Outer blade ange

V. Outer blade lock nut

W. Dust port adaptor*

X. Elbow joint dust port adaptor***

Y. Dual port adaptor*

Z. Dust hose*

STAND OVERVIEW

A1 - G. Stand Components

H1 - H2. Foot Pad Components

I. Wheels (x2)

J - P. Stand Fixings

ASSEMBLY

WARNING: To reduce risk of injury, disconnect the tool from

the power source before installing, repositioning or removing

accessories. Only connect the plug to the power source just

before starting the saw.

• Assembling the stand** (figs. 1)

• Assembling the outfeed support* (fig. 2)

• Assembling the blade and riving knife (fig. 3)

SETTING UP THE SAW

• Using the rack and pinion fence (fig. 4)

Note: The fence can be installed in three positions atop the screws

installed in the extending rails (fig. 4.1). Use position A for left

positioning, position B for 0-550mm ripping, and position C for

100-650mm ripping.

• Aligning the rack and pinion fence (fig. 5)

• Adjusting the cutting height (fig. 6)

• Using the push stick for rip cutting (fig. 7)

OPERATION

• Powering the tool on/off (fig. 8)

• 90

º

cutting (fig. 9)

• Bevel cutting (fig. 10)

• Mitre cutting (fig. 11)

• Using the extended table (fig.12)

• Attaching the clamp (fig.13)

• Dust extraction (fig. 14)

• Transporting the saw (fig. 15)

• Adjusting the kerf plate height (fig. 16)

MAINTENANCE

• Checking riving knife and blade parallelism (fig. 17)

• Checking the blade at 45

º

(fig. 18)

*Models R255TBL+ and R255TBLX+ only.

**Models R255TBLX and R255TBLX+ only.

***Models R255TBL and R255TBLX only.

Loading...

Loading...