14

www.evolutionpowertools.com

INSTALLING OR REMOVING A BLADE

WARNING: Only attempt these procedures with the machine

disconnected from the mains power supply.

Note: We recommend that the operator wears protective gloves

when handling blades. Care should be exercised as a recently

used blade could be hot and/or contaminated with debris.

To install a blade:

• Ensurethatthebladeholderiscleanandfreefromdebrisor

other contaminates.

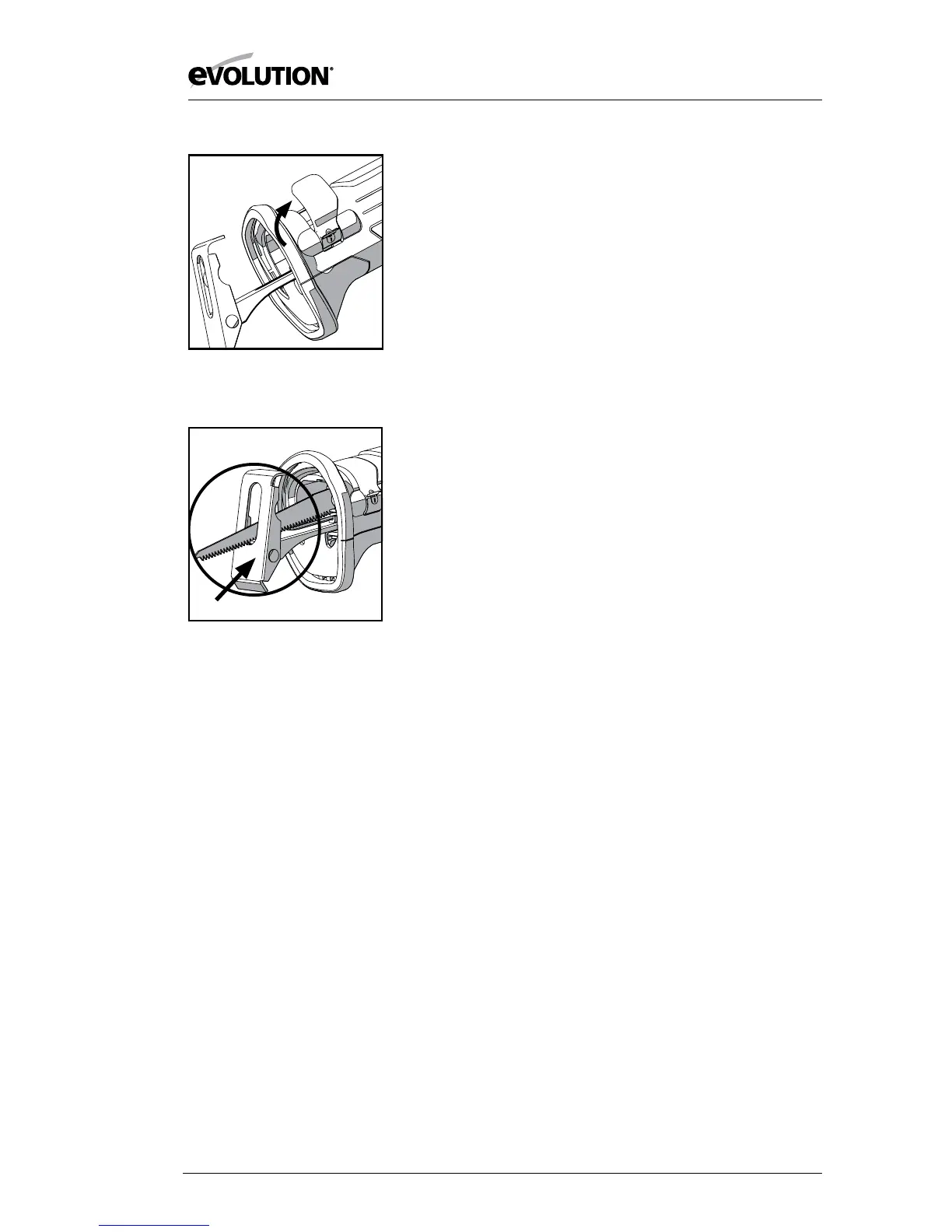

• Operatethebladeclampingleverto‘open’thebladeholder.

(Fig. 1)

• Inserttheshankofthebladeintothebladeholderensuring

that it is pushed fully ‘home’.

WARNING: It is important that the hole in the tang of the blade

engages with the ‘spigot’ located inside the blade holder.

• Allowthebladeclampinglevertoreturntoitsserviceposition.

• Conducta‘tugtest’toensurethatthesawbladehasbeen

securely ‘captured’ by the blade holder.

To remove a blade:

• Ifrecentlyusedallowthebladetocooldown.

• Ensurethatthemachineisfacingdownwardstoallow

any debris to fall out.

• Operatethebladeclampinglever.

• Gentlypullthebladefromthebladeholder.

Note: If a blade is being removed because it is at the end of its

service life eject it straight into a recycling bin.

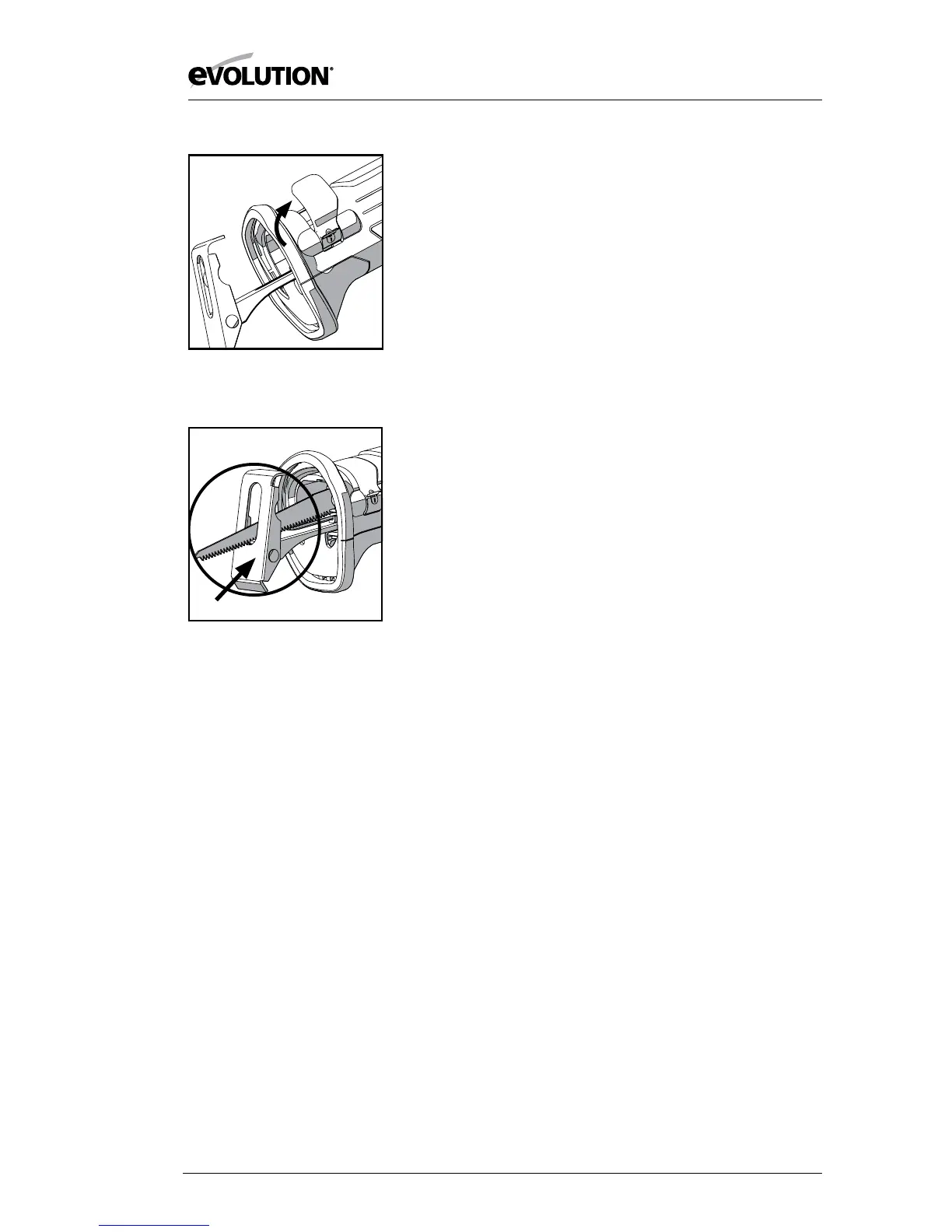

WORKPIECE CONTACT PLATE (Fig. 2)

WARNING: During cutting operations to achieve best cutting

eciency, and to minimise the risk of vibration, blade jumping

and/or breakage, the workpiece contact plate must, at all times,

be kept rmly in contact with the workpiece.

Note: The workpiece contact plate is pivoted. This feature

allowsthecontactplatetoadjustautomaticallyandlieushon

a workpiece surface even when the machines main body is at a

slight angle to that surface.

Fig. 1

Fig. 2

Loading...

Loading...