15

www.evolutionpowertools.com

EN

DE

FR

CUTTING REACH & CAPACITY

By using dierent length blades and/or altering the service

position of the workpiece contact plate, it is possible to increase or

decrease the overall ‘reach’ and cutting capacity of the machine.

To adjust the position of the workpiece contact plate:

• Loosenthetwosocketheadedscrews(Fig. 3)

Note: A hex key for these socket headed screws is provided.

The dedicated storage holder for this hex key is located on the

main power cable where it enters the ‘D’ handle.

Always return this hex key to its dedicated storage position

once adjustment has been completed.

• Slidetheworkpiececontactplateinoroutasrequired.

• Securelytightenthesocketheadedscrews.

• Checkthesettingofthemachinebeforebeginning

cutting operations.

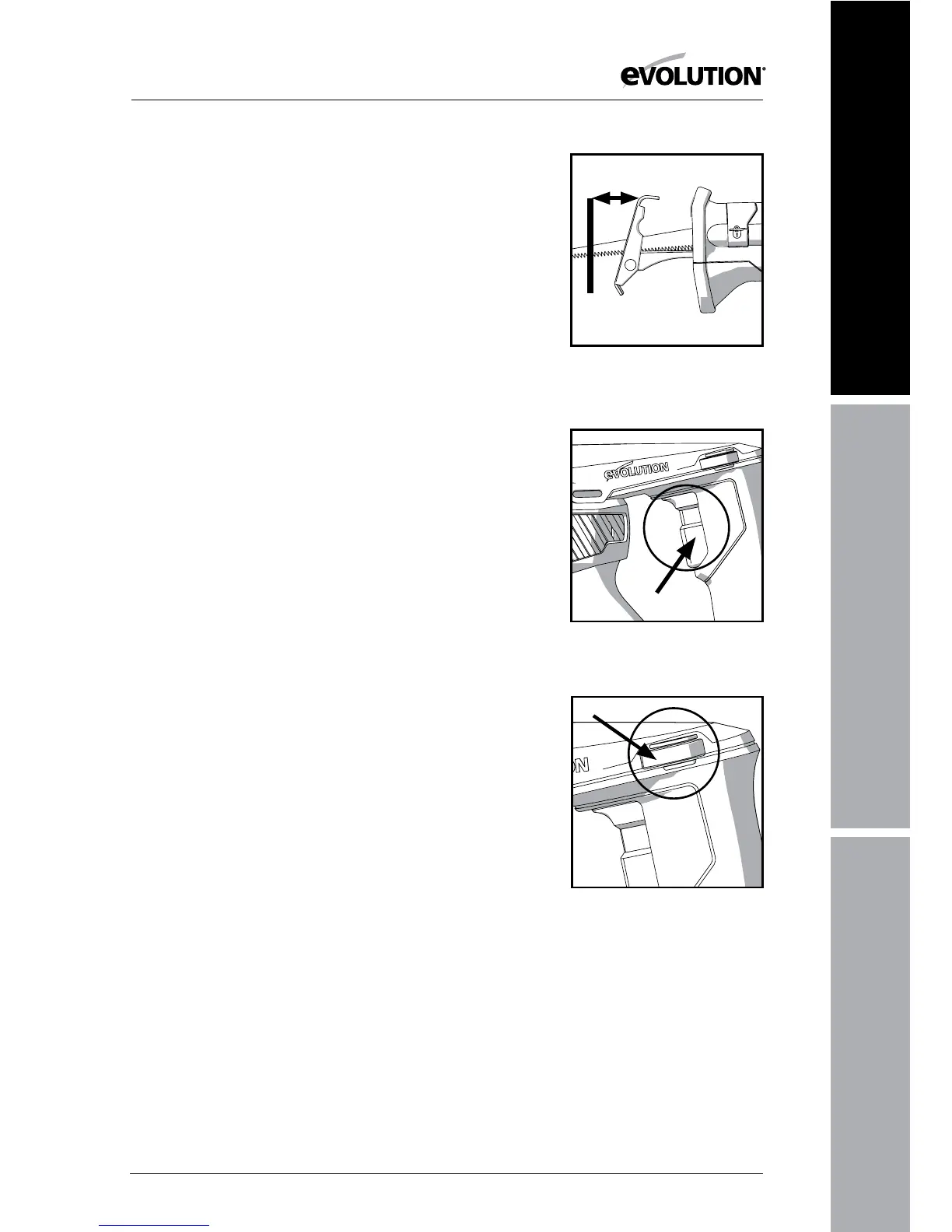

THE TRIGGER SWITCH

The ON/OFF trigger switch is ergonomically located within

the machines main rear ‘D’ handle. (Fig. 4). It is a non-latching

type switch.

• Squeezethetriggerswitchtostartthemachinesmotor.

• Releasethetriggerswitchtostopthemachinesmotor.

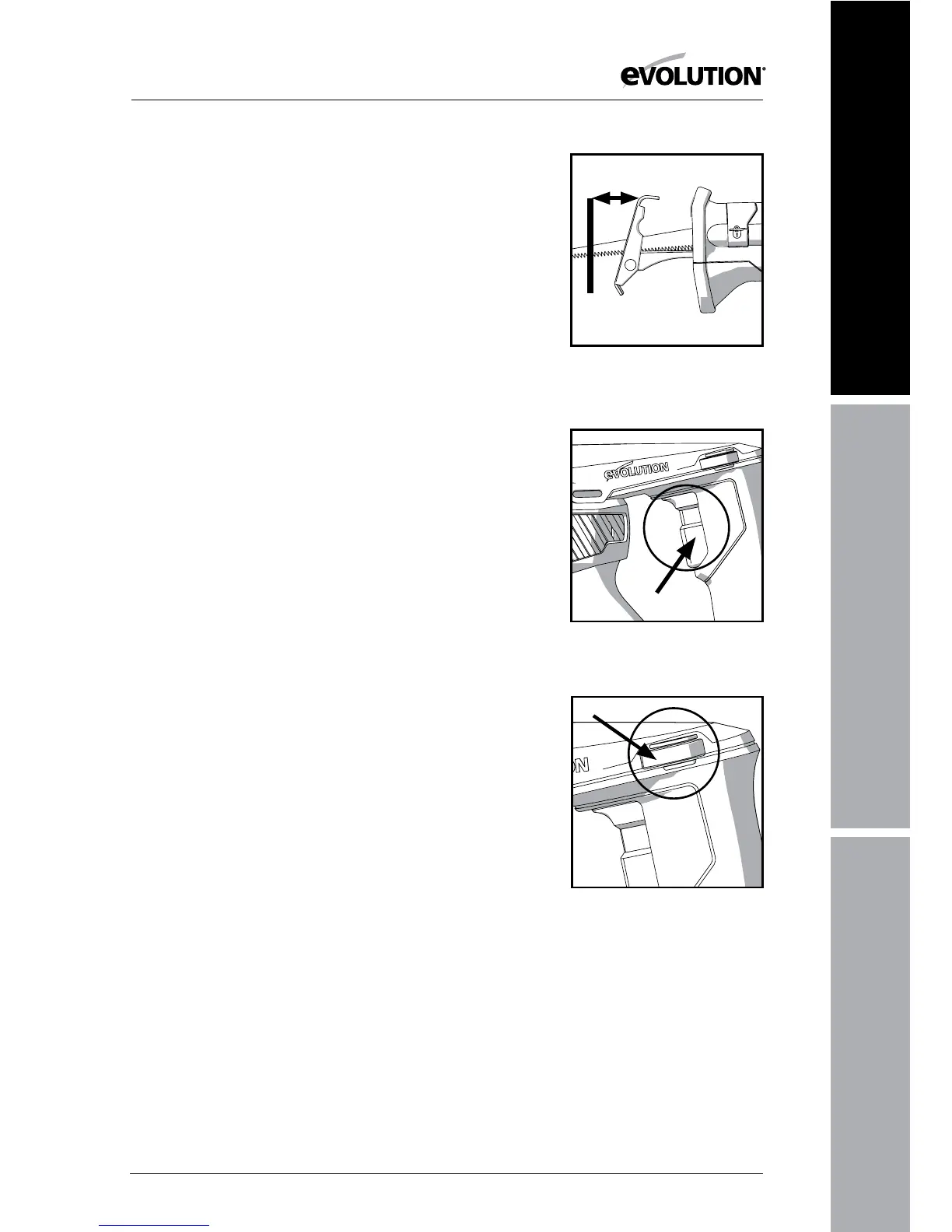

THE STROKE RATE CONTROL DIAL

The stroke rate of the machine can be varied. A stroke rate

control dial is located on the LH (left hand) side of the ‘D’

handle. (Fig. 5).

Note: The ergonomic positioning of this control dial just above

the trigger switch, allows a skilled operator to adjust the stroke

rate of the machine during cutting operations.

Rotating this dial will alter the stroke rate of the machine from

approximately 800 strokes a minute up to a maximum of 2400

strokes per minute.

Note: We recommend that the operator begins any cutting

operation using a slow stroke rate, and increases the stroke rate

to achieve optimum performance as cutting progresses.

Fig. 4

Fig. 5

Fig. 3

Loading...

Loading...