16

www.evolutionpowertools.com

A practical trial on scrap material may be useful to determine

the best stroke rate for any particular material or application.

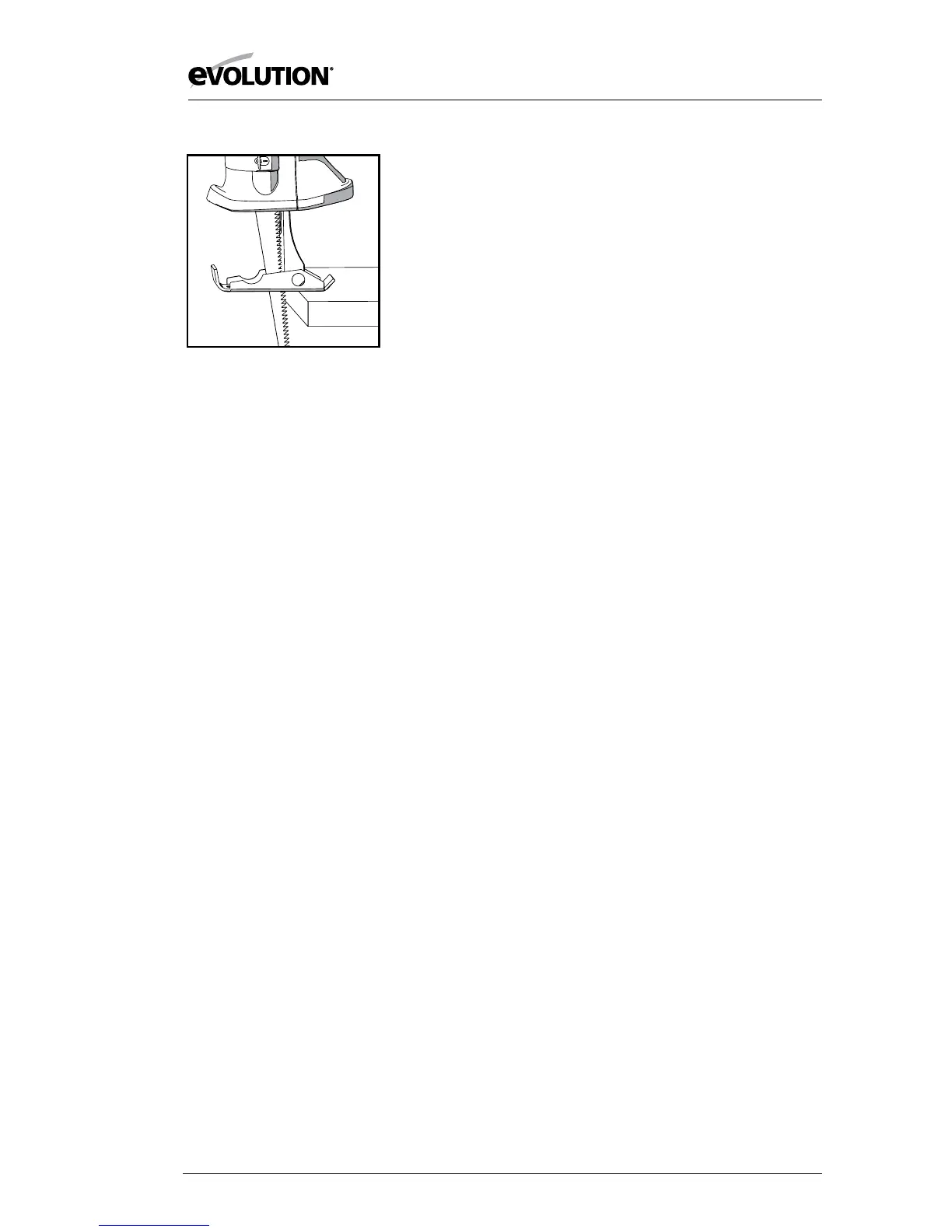

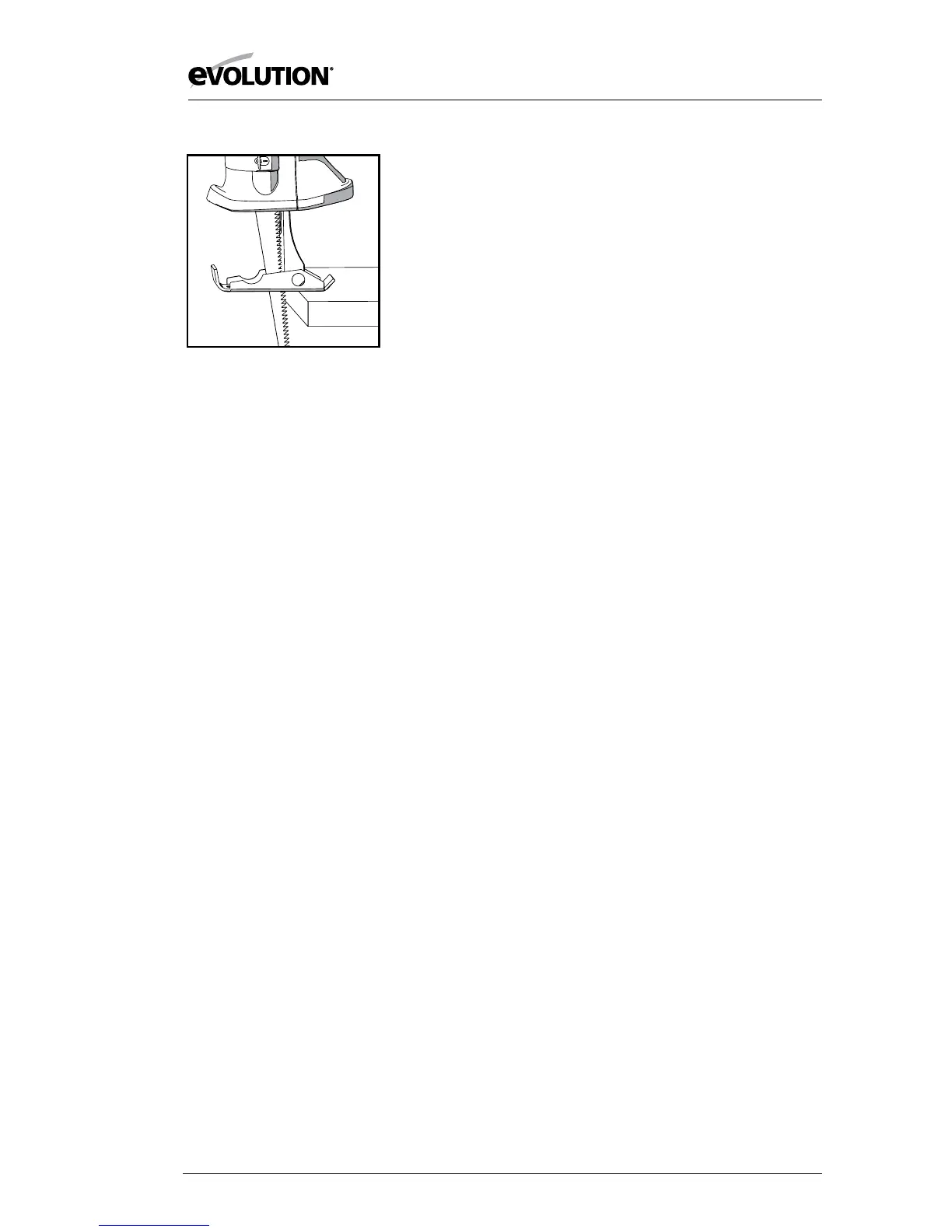

GENERAL CUTTING

WARNING: Never start the machine with the blade in contact

with the workpiece.

• Selectalowstrokerate.

• Holdthemachinewithbothhands.

• Ensurethattheworkpiececontactplateisrmlyincontact

with the workpiece but that the blade is not. (Fig. 6).

• Switchonthemachine.

• Verygradually,andholdingthemachinermly,introducethe

blade into the workpiece until it is cutting successfully.

• Operatethestrokeratecontroldialuntiloptimumcutting

performance is achieved.

• Never‘force’theblade.Allowthebladetocutthroughthe

workpiece without applying undue pressure. Forcing the

blade will reduce blade life, increase the likelihood of blade

breakage, and put strain on the machines motor.

WARNING: If the saw blade should jam, switch o the machine

immediately and disconnect from the mains supply.

JAMMED BLADES

WARNING: Jammed blades may be very hot and/or

contaminated with debris. The operator should exercise great

caution when attempting to remove a ‘jammed’ blade,

and employ all necessary PPE.

To remove a jammed blade the kerf (the saw cut made by the

blade) will have to be widened.

• Removethemachinefromthebladebyoperatingtheblade

clamping lever, and carefully easing the machine from the

jammed blade.

• Widenthekerfwithasuitabletooluntilthebladecanbe

pulled from the workpiece.

PLUNGE CUTTING

WARNING: Plunge cutting is a technique that must only be

used on soft building materials such as plasterboard etc. It is

not a suitable procedure for use on harder materials, and must

never be employed on metallic materials.

Note: This technique should not be attempted by

inexperienced operatives.

Fig. 6

Loading...

Loading...