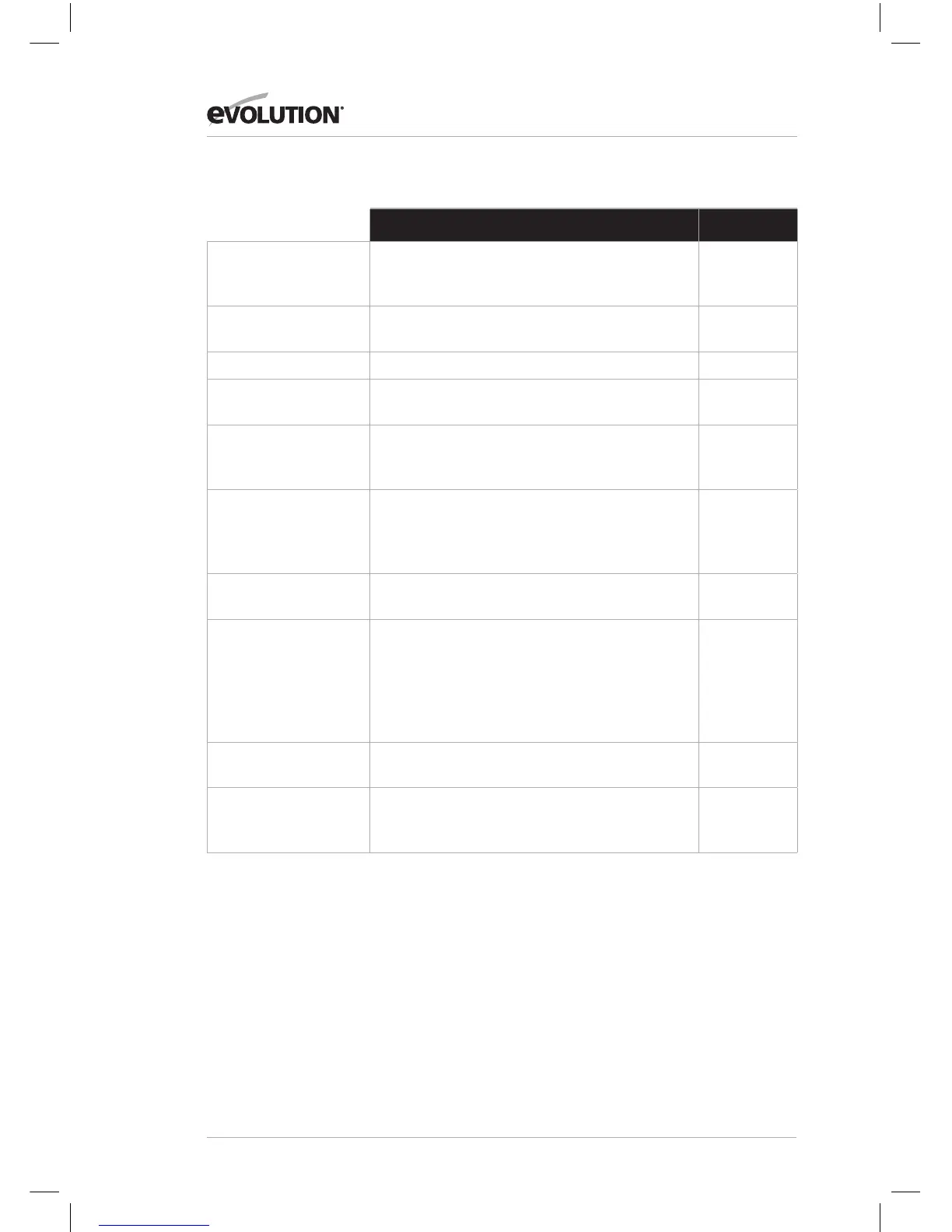

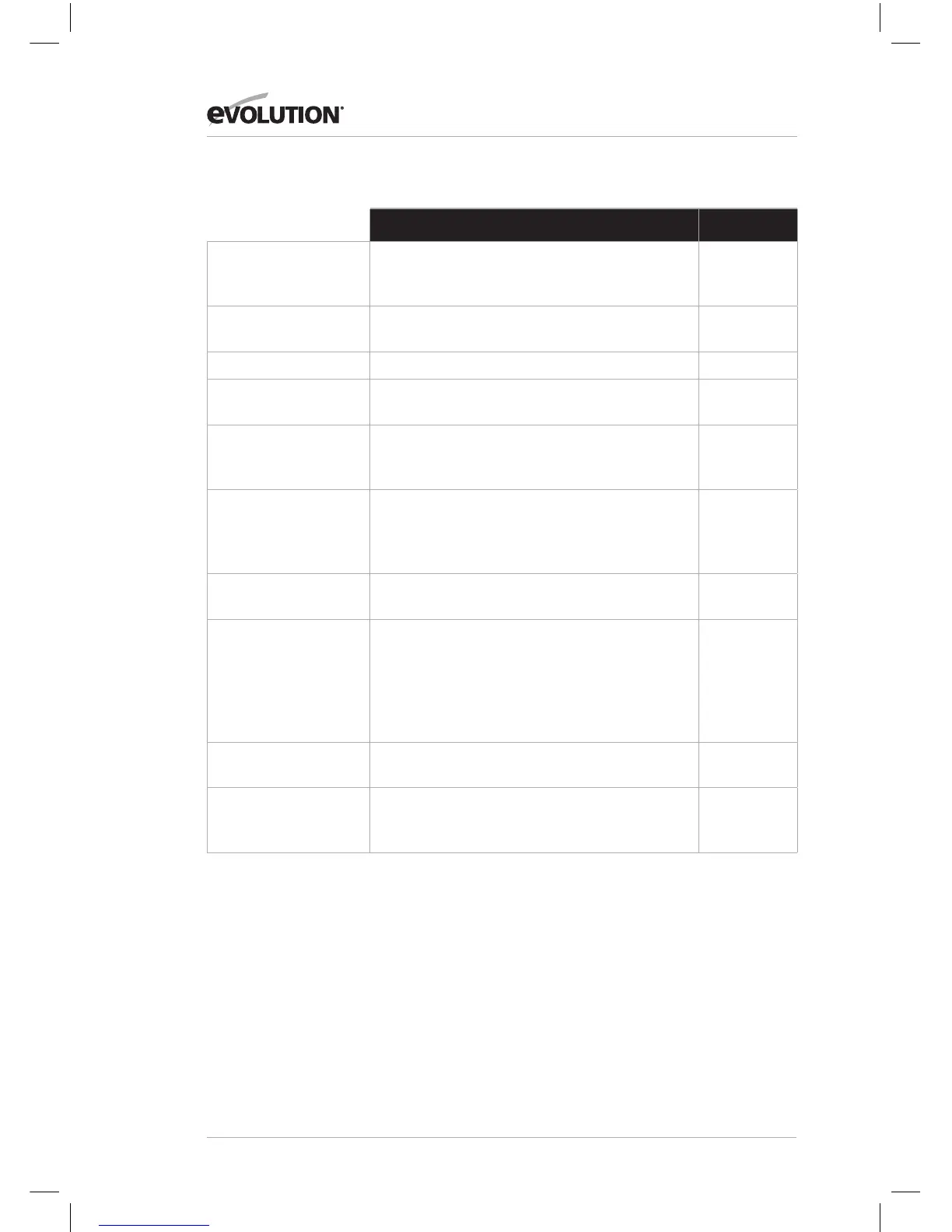

FINAL SAFETY CHECKS

Condition Yes

Slides Inserted through the Bevel Neck and connected

to the Cutting Head. Locating lugs successfully

deployed

Positive Stop Locking

Lever

Installed onto Locking Mechanism

Mitre Locking Handle Installed onto Locking Screw

Power Cable Routed correctly and fastened to back slide bracket.

50 – 60mm max deflection at the midpoint

Blade Blade installed with rotation arrows matching.

Outer blade flange and arbor bolt and washer

correctly fitted

Safety Guards Lower Safety Guard fully operational. Cutting Head

locks in the upper position with blade covered.

Cutting Head can only be lowered when Blade

Guard Locking trigger is operated

Supply Supply matches specification found on machine

Rating Plate. Plug matches power source outlet

Mounting Either:

a) Machine permanently sited and bolted

to workbench

b) Machine mounted on board which is clamped to

workbench (for portable use)

c) Machine bolted to a dedicated Mitre Saw Stand

Sited Adequate provision made for the handling of long

or irregular shaped workpieces

Environment Dry, clean and tidy. Temperature conducive to

material handling. Lighting adequate (double

banked if fluorescent lights are used).

All the Yes Boxes must be ticked before the machine can be used.

No tick = No use.

36

www.evolutionpowertools.com

Loading...

Loading...