16

the blade.

To install a standard blade:

• Place the new blade on the arbor shaft ( the

teeth must point down toward the front of the

saw to work properly).

• Place the blade washer and the blade nut over

the arbor shaft. Be sure the dome side of the

blade washer faces the blade and that all items

are snug against the arbor housing. Make sure

the blade nut is securely tightened. Do not

overtighten.

• Lock the release lever.

• Rotate the blade by hand to make sure it turns

freely.

• Lower the saw blade and reinstall the table

insert.

NOTE: To replace the blade with an accessory

blade, follow the instructions provided with the

accessory.

9. Using the saw

The operation of power tools involves a certain

amount of hazard for the operator. Before

attempting regular work we recommend you get

the feel of operations using scrap lumber to

check settings. Read entire instructions before

you start to cut workpiece. Always pay attention

to safety precautions to avoid personal injury.

WARNING!

Make sure the blade guard assembly is installed

and working properly to avoid serious possible

injury.

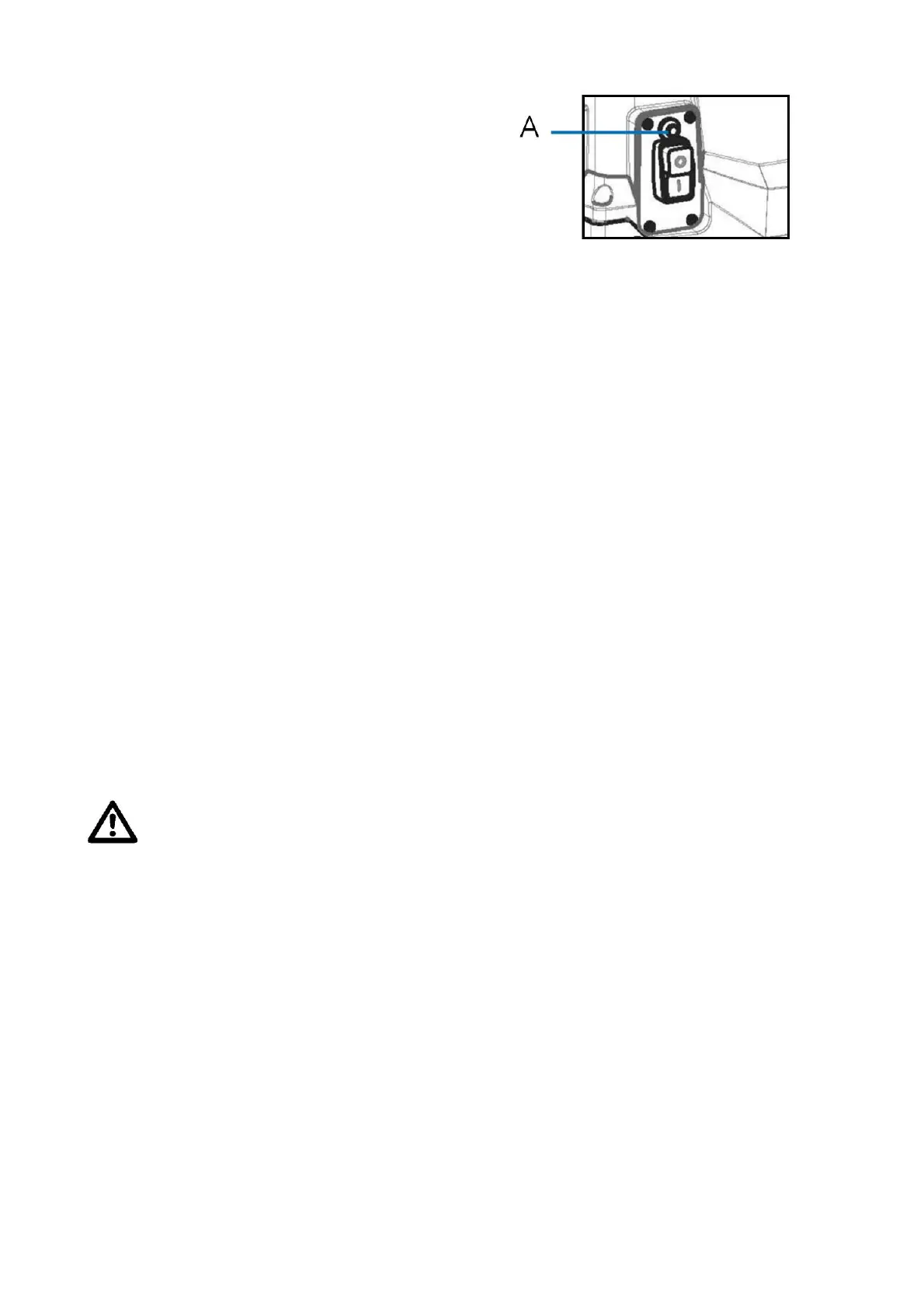

9.1. ON/OFF switch

• To turn the saw on, press the green

button “I”. Wait for the blade to reach its

maximum speed of rotation before commencing

with the cut.

• To turn the machine off again, press the

red button “O”.

9.2. RESET BUTTON (OVERLOAD

PROTECTOR)

This saw comes with an overload reset button,

If the saw motor over loads, a safety

mechanism stops the motor automatically due

to motor over-loading or low voltage. To prevent

motor over-load, reduce load on motor or check

voltage.

Allow motor to cool down, then press the reset

button and restart the saw. If the saw does not

restart, wait an additional 5 minutes before

restarting.

9.3. Cutting aids

Push sticks are devices that may be used for

pushing a workpiece through the blade in any

rip cut. When making non-through cuts or

ripping narrow stock, always use a push stick,

push block, and/or feather- board so your hands

do not come within 3 inches of the saw blade.

They can be made in various sizes and shapes

from scrap wood and used in a specific project.

The stick must be narrower than the workpiece,

with a 90˚ notch in one end and shaping for a

grip on the other end.

A push block has a handle fastened by

recessed screws from the underside. Use push

blocks for narrow cuts and all non-through cuts.

NOTICE: Be sure the screws in a push block

are recessed to avoid damaging the saw or

workpiece.

9.4. To use the miter gauge The miter gauge

provides greater accuracy in angled cuts. For

very close tolerances, test cuts are

recommended. There are two miter gauge

grooves, one on either side of the blade. When

making a 90° cross cut, you can use either miter

Loading...

Loading...