Maintenance

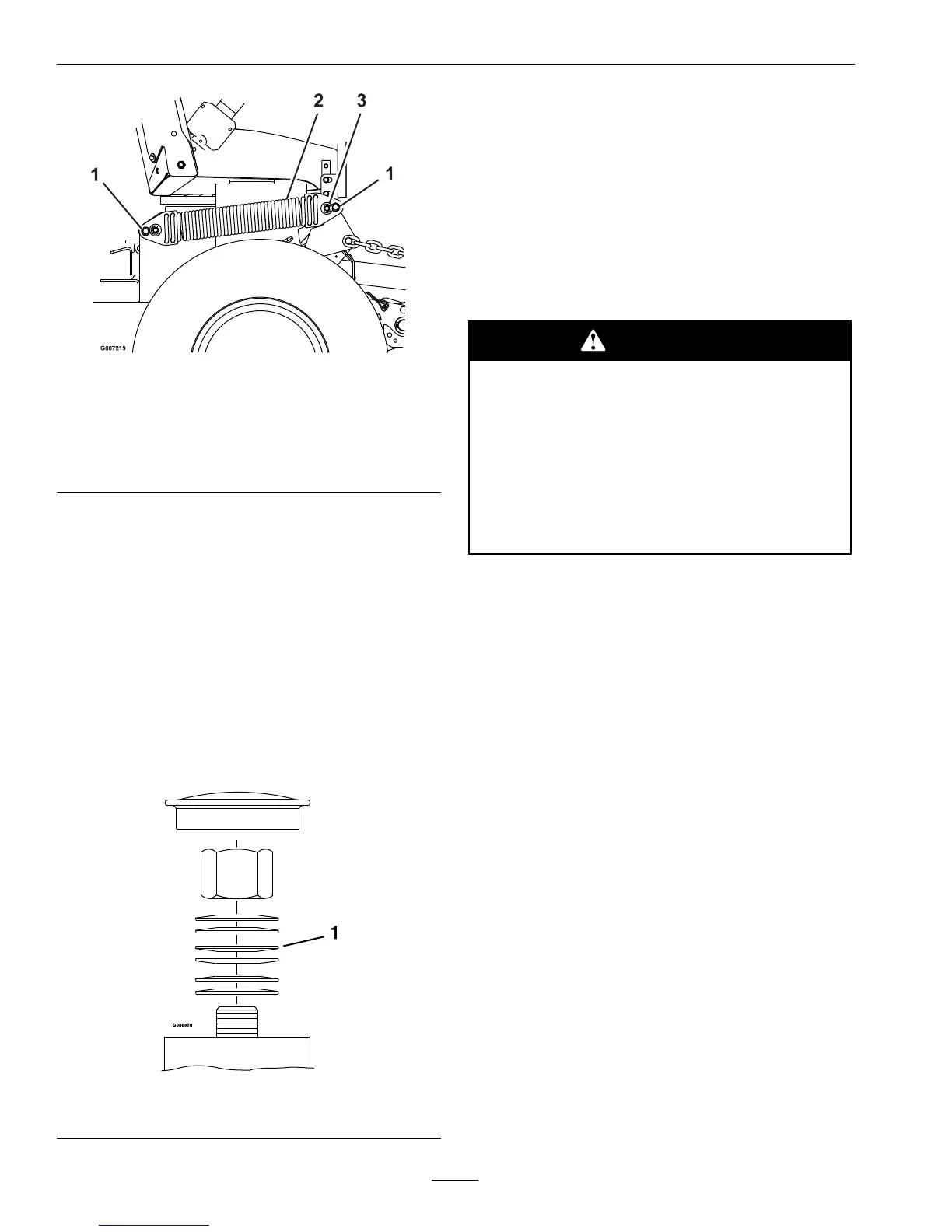

Figure16

Right-HandSideofUnitShown

1.Re-installspringinouter

holestoreducespring

tension.

3.Removee-ringand

washer.

2.Weighttransferspring.

7.Re-installtheleftfender

8.Foradditionalweighttransferadjustment,repeat

steps4through7ontherightsideoftheunit.

CasterPivotBearings

Pre-LoadAdjustment

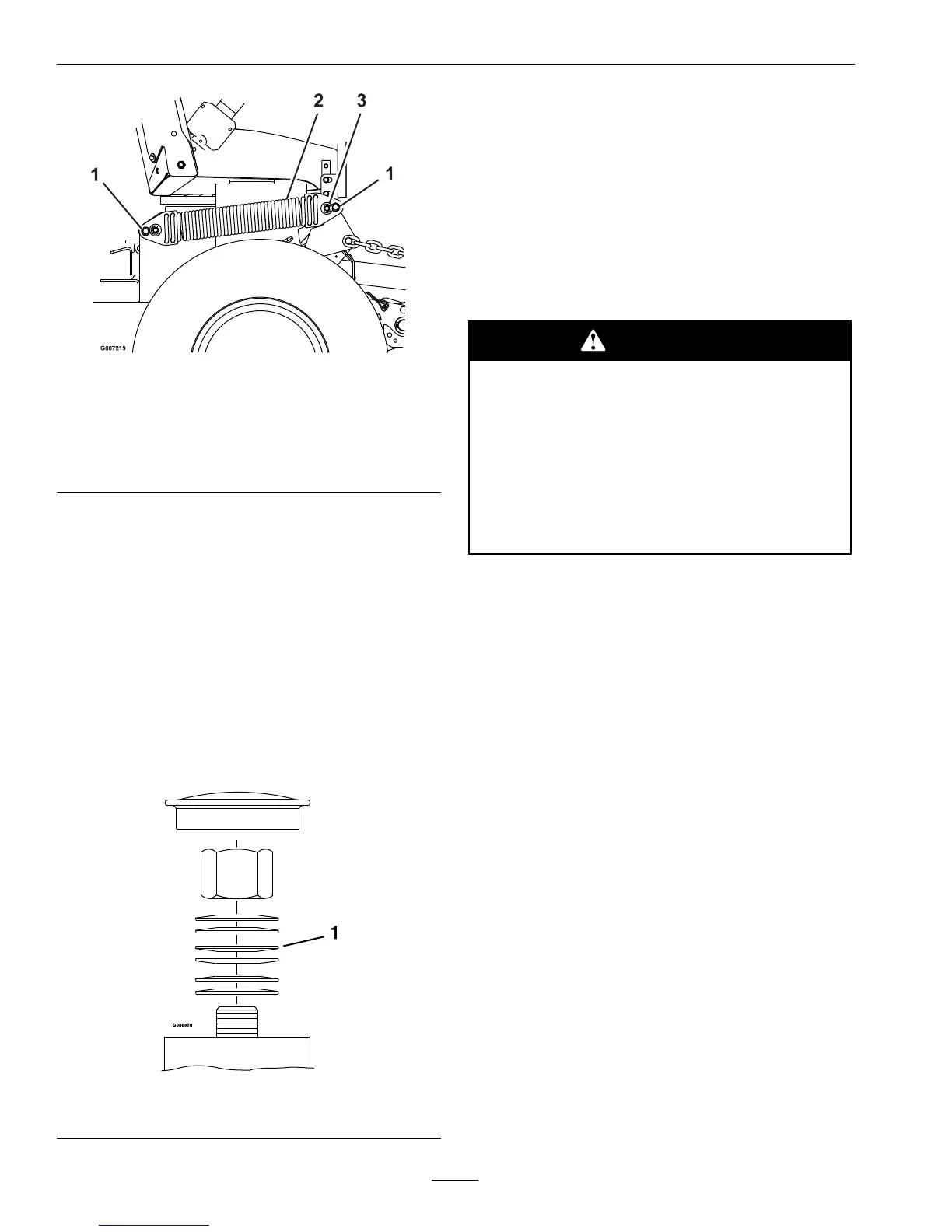

Removedustcapfromcasterandtightennylocnut

untilwashersareatandbackoff1/4ofaturn

toproperlysetthepre-loadonthebearings.If

disassembled,makesurethespringdiscwashersare

reinstalledasshowninFigure17.

Figure17

1.Springdiscwashers

Cleaning

CleanEngineCooling

System

ServiceInterval:Beforeeachuseordaily

(Mayberequiredmore

oftenindryordirty

conditions.)

CAUTION

Excessivedebrisaroundtheenginecooling

airintakeandinsideofthepumpdrive

beltcompartmentanddamagedormissing

rubberbafescancausetheengineand

hydraulicsystemtooverheatwhichcan

createarehazard.

Cleanalldebrisfrominsideofpumpdrive

beltcompartmentdaily.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Cleanalldebrisfromrotatingengineairintake

screenandfromaroundengineshrouding.

3.Cleanalldebrisfromaroundtheengineanddrive

belts.

RemoveAccumulatedDebris

fromEngine(Briggs&

StrattonUnitsOnly)

ServiceInterval:Beforeeachuseordaily

Enginepartsshouldbekeptcleantoreducetherisk

ofoverheatingandignitionofaccumulateddebris.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Removefrontpanelfromengineandcleanaround

theintakemanifold,fuelpump,andcarburetor.

3.Reinstallthefrontpanel.

Important:DoNotusewatertocleanengine.

Uselowpressurecompressedair.SeeEngine

Owner’sManual.

34

Loading...

Loading...