Maintenance

Checktomakesurebrakeisadjustedproperly.This

proceduremustbefollowedaftertherst100hours

orwhenabrakecomponenthasbeenremovedor

replaced.

1.Drivethemachineontoalevelsurface.

2.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallocked

positionandengagetheparkingbrake(leverisin

the“up”position).

3.Stoptheengine,waitforallmovingpartstostop,

andremovethekey.

4.Raisethebackofthemachineupandsupportthe

machinewithjackstands.

CAUTION

Raisingthemowerdeckforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.The

mechanicalorhydraulicjacksmaynotbe

enoughsupportormaymalfunctionallowing

theunittofall,whichcouldcauseinjury.

DoNotrelysolelyonmechanicalorhydraulic

jacksforsupport.Useadequatejackstands

orequivalentsupport.

5.Removethereartiresfromthemachine.

6.Removeanydebrisfromthebrakearea.

7.Rotatethedrivewheelreleasehandletothe

“released”position.RefertotheDriveWheel

ReleaseValvessectioninOperation.

8.Checktoseeifthereisavisiblegapbetweenthe

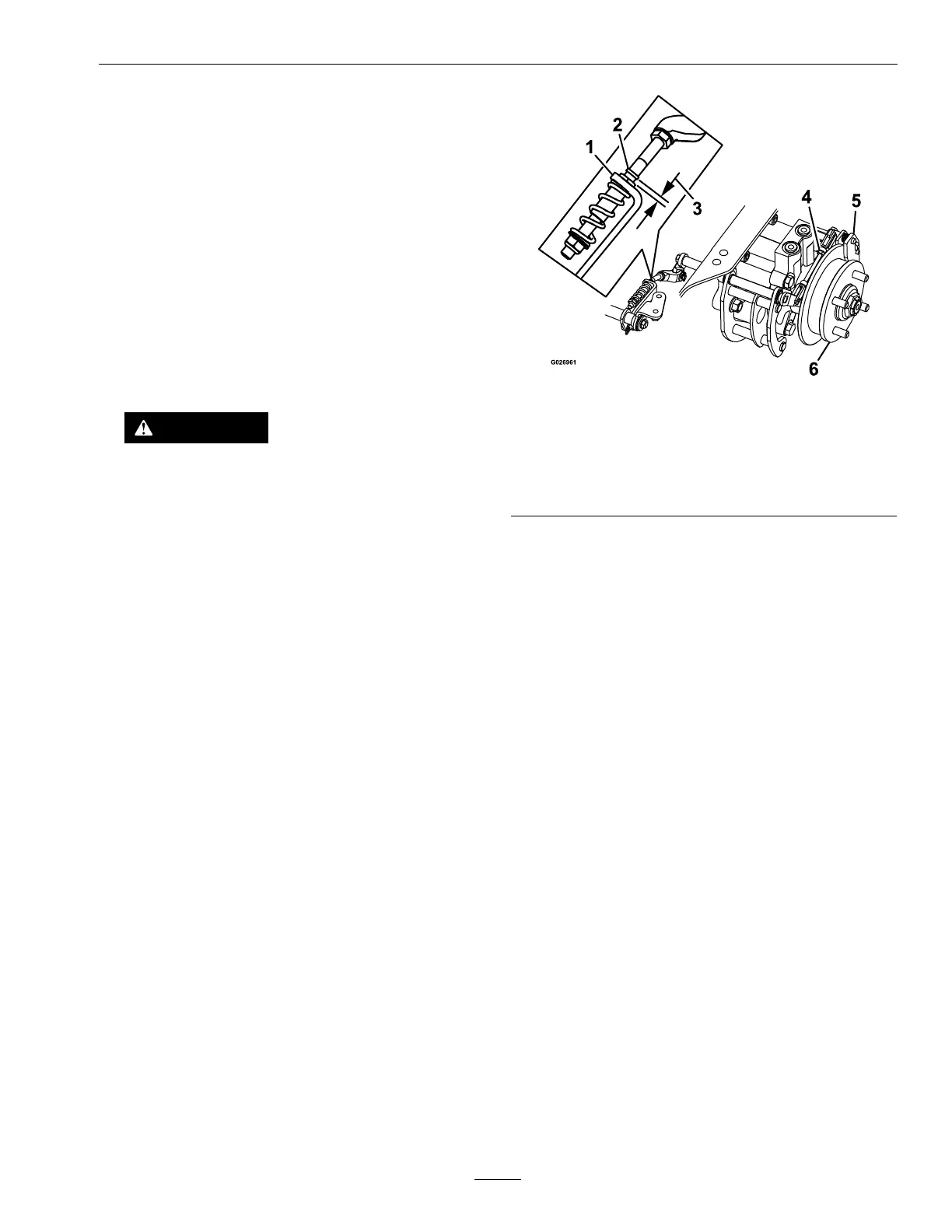

L-bracketandthelinkagestop(seeFigure42).

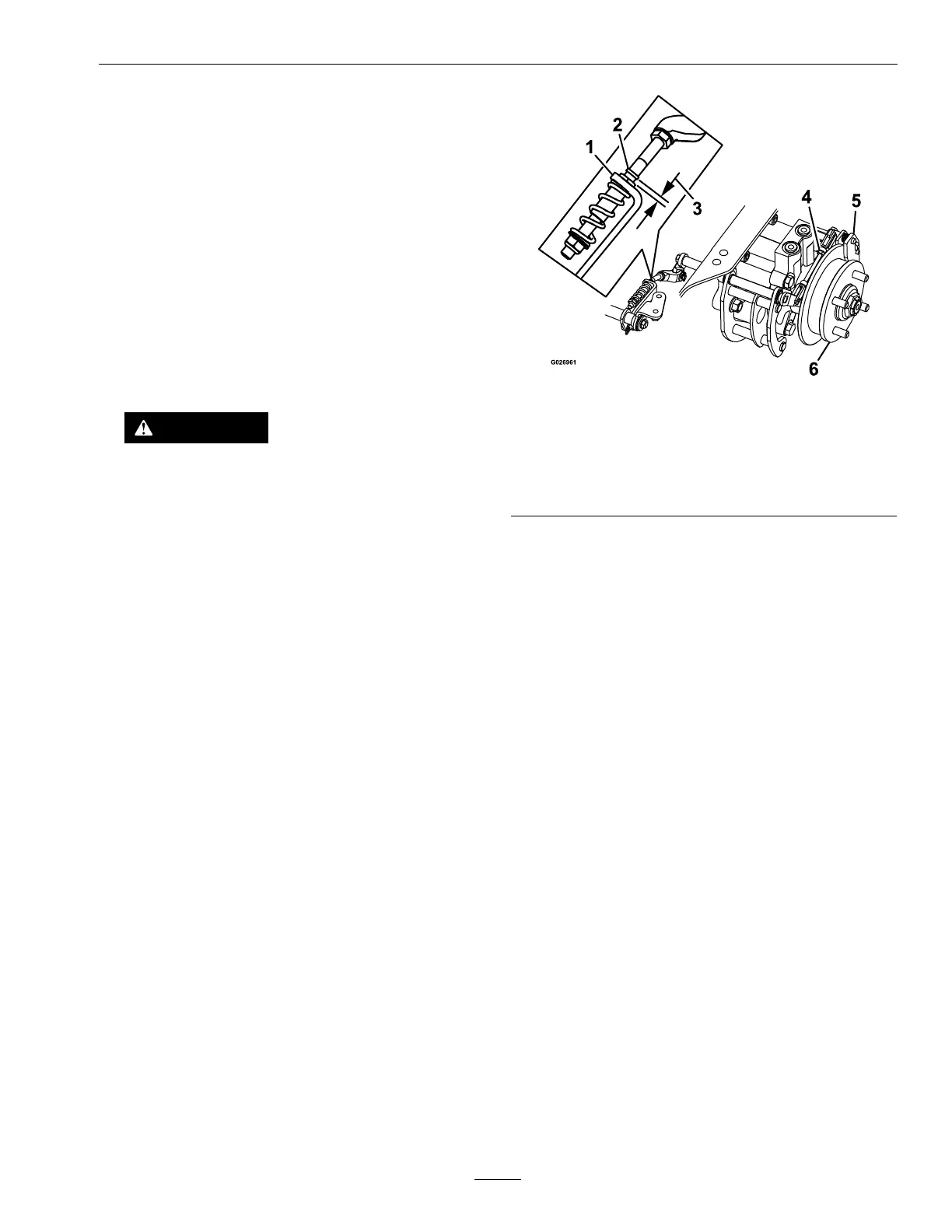

Figure42

LeftSideShown

1.L-bracket4.Rearlinkageassembly

2.Linkagestop

5.Caliper

3.Gap

6.Wheelhub

9.Disengagetheparkbrake,thelevershouldbein

thedownposition.Turnthewheelhubbyhand

inbothdirectionsrelativetothecaliper;thewheel

hubshouldmovefreelybetweenthecaliper.

10.Ifagapisneededorthewheelhubdoesnot

movefreely:

A.Disengagetheparkbrake.

B.Disconnectandne-tunetherearlinkage

assembly:

•Shortenthelinktocreateagap.

•Lengthenthelinktoallowwheelhub

movement.

C.Reconnecttherearlinkageassembly.

11.Engagetheparkingbrakeandcheckthegap.

12.Repeatsteps9through12untilavisiblegapis

achievedandthewheelhubrotatesfreely.Repeat

forthebrakeontherightside.

13.Rotatethedrivewheelreleasehandletothe

“operating”position.RefertotheDriveWheel

ReleaseValvessectioninOperation.

14.Installthereartiresandtorquelugnutsto85-105

ft-lb(115-142N-m).

15.Removejackstands.

53

Loading...

Loading...