Maintenance

RemovingtheSparkPlug

1.DisengagethePTOandensuretheparkingbrake

isengaged.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

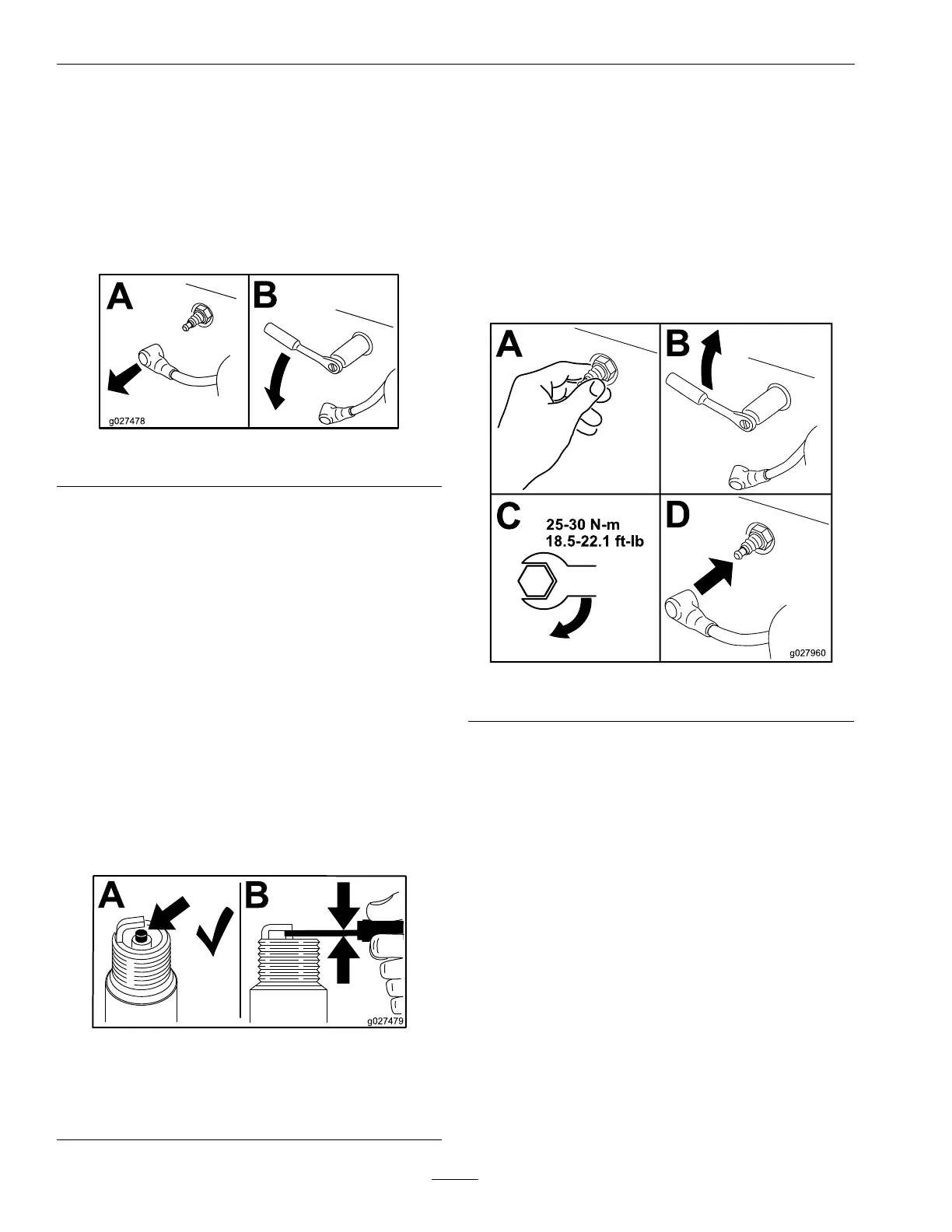

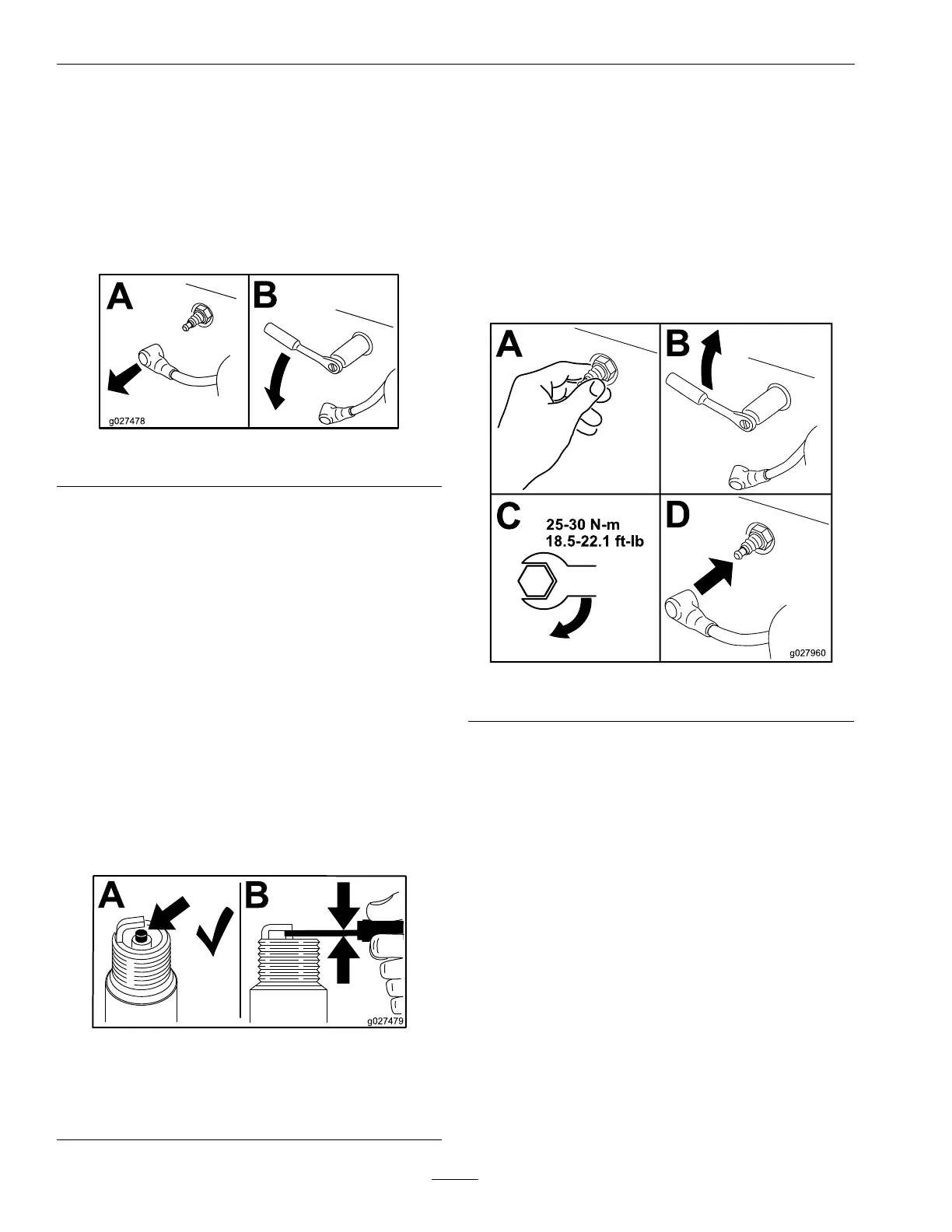

3.Disconnectthewirefromthesparkplug.

g027478

Figure55

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

CheckingtheSparkPlug

1.Inspectthesparkplug

Note:Ifyouseelightbrownorgrayonthe

insulator,theengineisoperatingproperly.A

blackcoatingontheinsulatorusuallymeansthe

aircleanerisdirty.

Important:DoNotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:

ablackcoating,wornelectrodes,anoilylm,

orcracks.

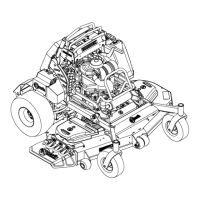

g027479

Figure56

1.Centerelectrode

insulator

3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandside

electrodes.

3.Setthegapto0.030inch(.76mm).

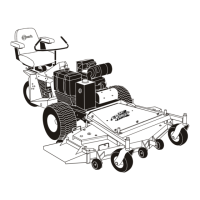

InstallingtheSparkPlug

1.Installthesparkplug.Makesurethattheairgap

issetcorrectly.

2.Tightenthesparkplugto18.5–22.1ft-lb(25–30

N-m).

g027960

Figure57

3.Pushthewireontothesparkplug.

CheckValveClearance

ServiceInterval:Every300hours—Check

valveclearance(Exmark

engine).

ContactanAuthorizedServiceDealer.

•Intake:.004–.006inches(.10–.15mm)

•Exhaust:.006–.008inches(.15–.20mm)

CheckandCleanCombustion

Chamber

ServiceInterval:Every300hours—Check

andcleancombustion

chamber(Exmarkengine).

ContactanAuthorizedServiceDealer.

54

Loading...

Loading...