Maintenance

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresult

inpersonalinjuryorpropertydamage.

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacearrester.

4.Ifpluggingofthescreenisobserved,remove

arresterandshakelooseparticlesoutofthe

arresterandcleanscreenwithawirebrush(soak

insolventifnecessary).Reinstallarresteron

exhaustoutlet.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”,

“Loctite243”,or“Fel-Pro,Pro-LockNutType”are

usedonthefollowingfasteners:

•ROPSspringpinhousing.

•Sheaveandclutchretainingboltintheendof

enginecrankshaft.

•Hydrocrossmembermountingbolts

Threadlockingadhesivesarerequiredforsome

hardwareonengines—seetheEnginemanual.

Copper-BasedAnti-seize

Copper-basedanti-seizeisusedinthefollowing

location:

OnthreadsofBladeBolts.SeeCheckMower

Bladessection.

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

Dielectricgreaseshouldnotbeappliedtosealed

connectors.

Adjustments

Note:DisengagePTO,shutoffengine,waitfor

allmovingpartstostop,engageparkingbrake,and

removekeybeforeservicing,cleaning,ormakingany

adjustmentstotheunit.

DeckLeveling

1.Positionthemoweronaatsurface.

2.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

3.Checkthetirepressureinthedrivetires.Proper

inationpressurefortiresis13psi(90kPa).

Adjustifnecessary.

4.Positionthetransportlockinthelatching

position.

5.Carefullyrotatethebladesfromsidetoside.

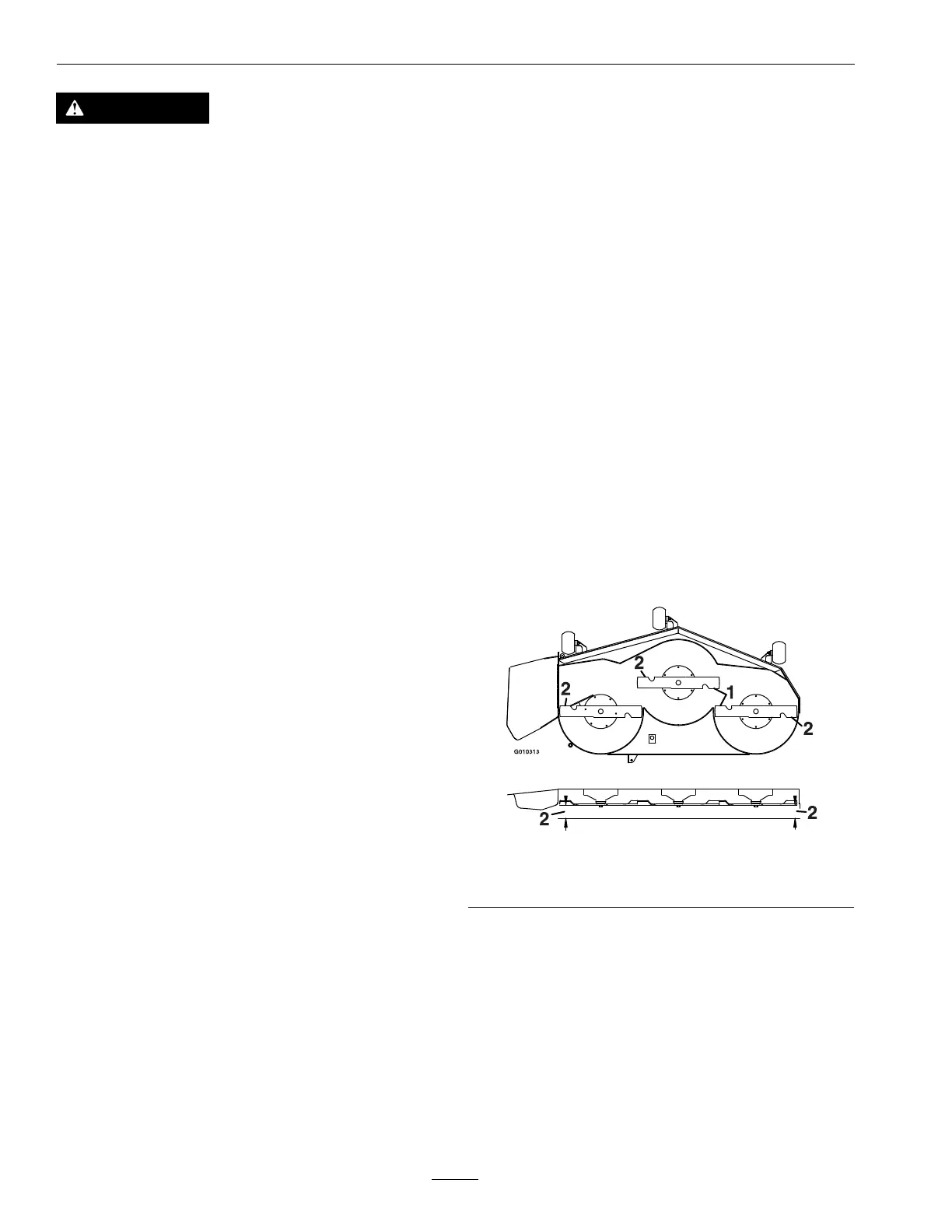

6.Measurebetweentheoutsidecuttingedgesand

theatsurface(Figure68).Ifbothmeasurements

arenotwithin3/16inch(5mm),anadjustmentis

required;continuewiththisprocedure.

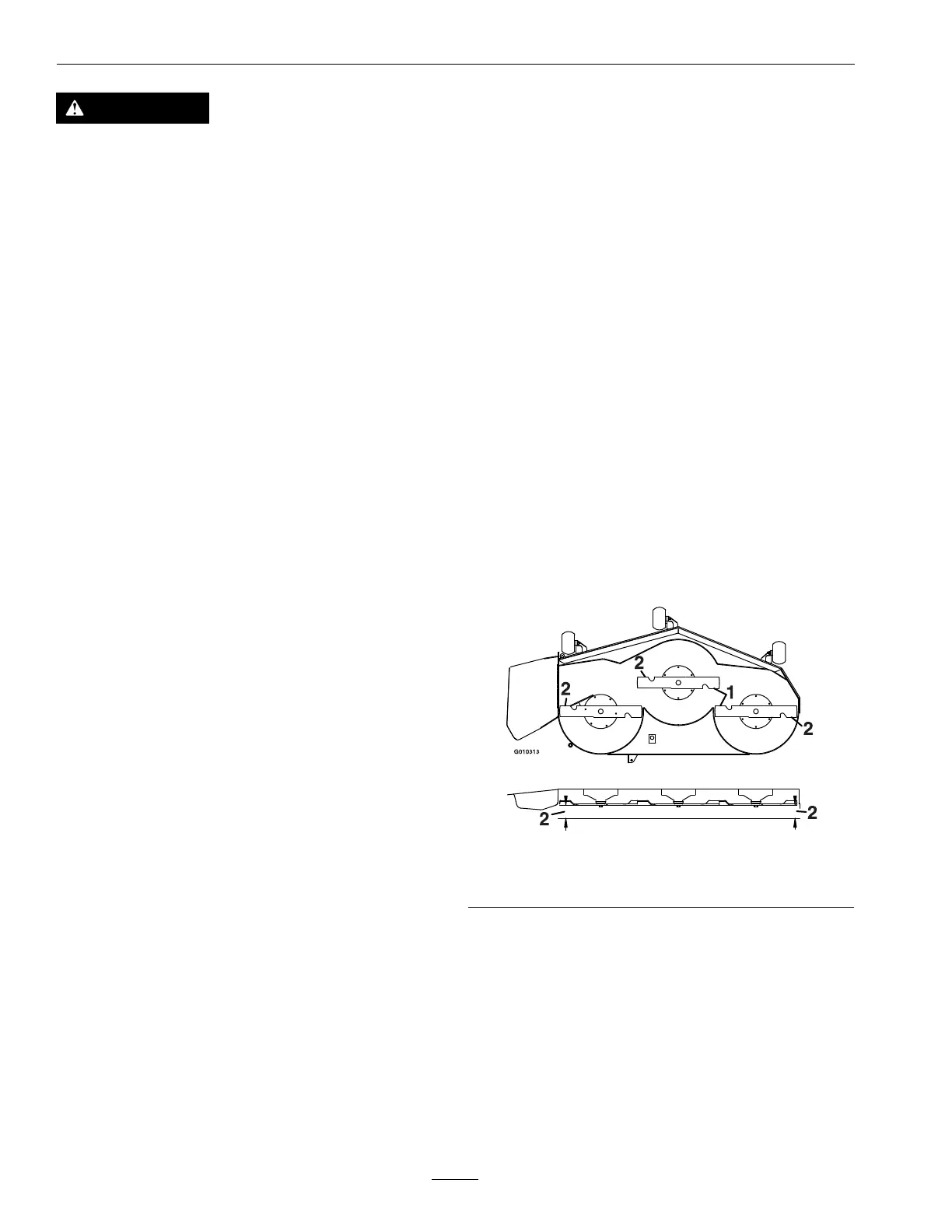

g010313

Figure68

1.Bladessidetoside2.Measurehere

7.Setanti-scalprollerstotopholesorremove

completelyforthisadjustment.

8.For60InchDecksOnly:

A.Raisethedecktothetransport(5inch(12.7

cm)cuttingheight)position.

B.Slowlyloosentheadjustingscrewonthe

liftassistspringuntilthescrewcanbe

removed(seeFigure69).Savethescrewfor

reinstallation.

66

Loading...

Loading...