Maintenance

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

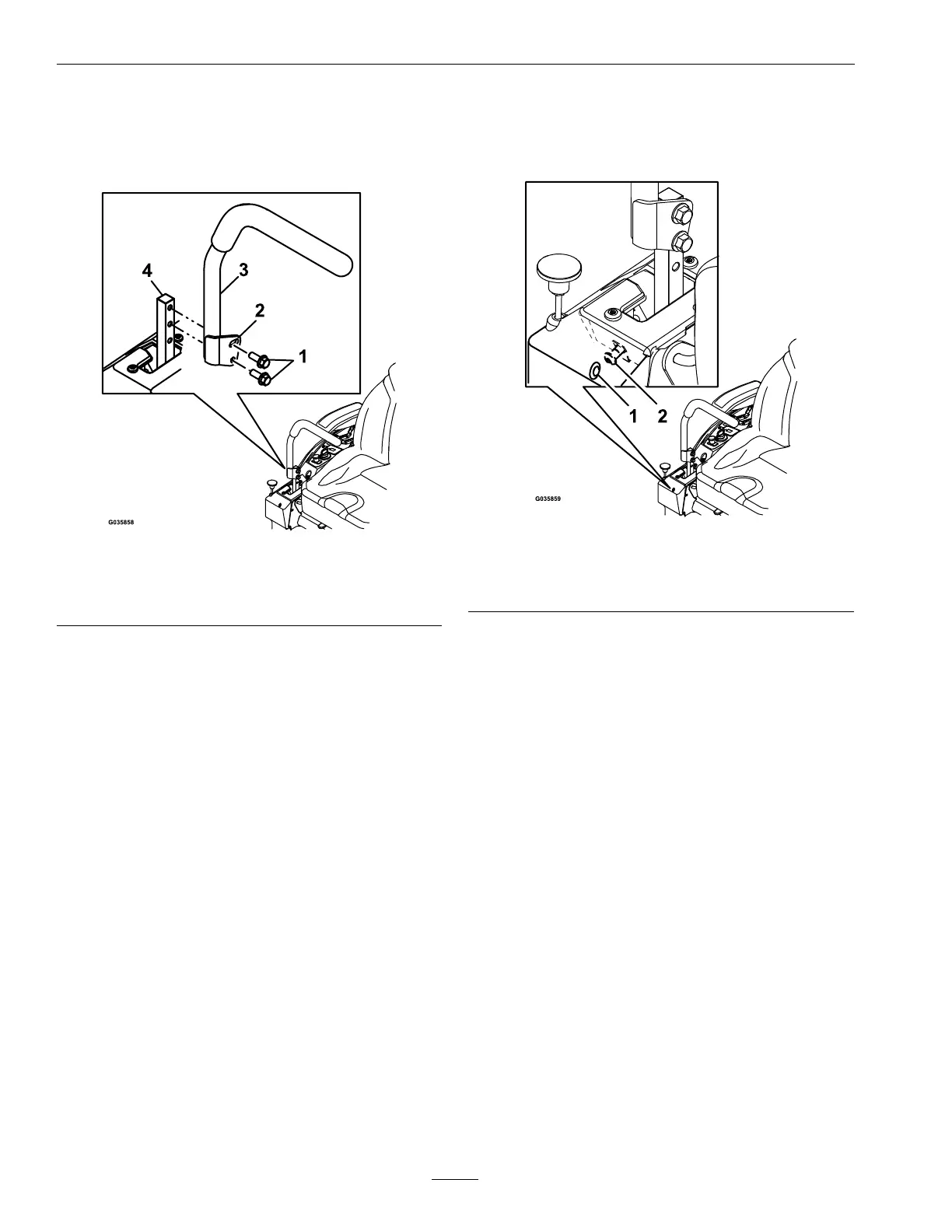

1.Removethehardwareholdingthecontrolleverto

thecontrolarmshaft.

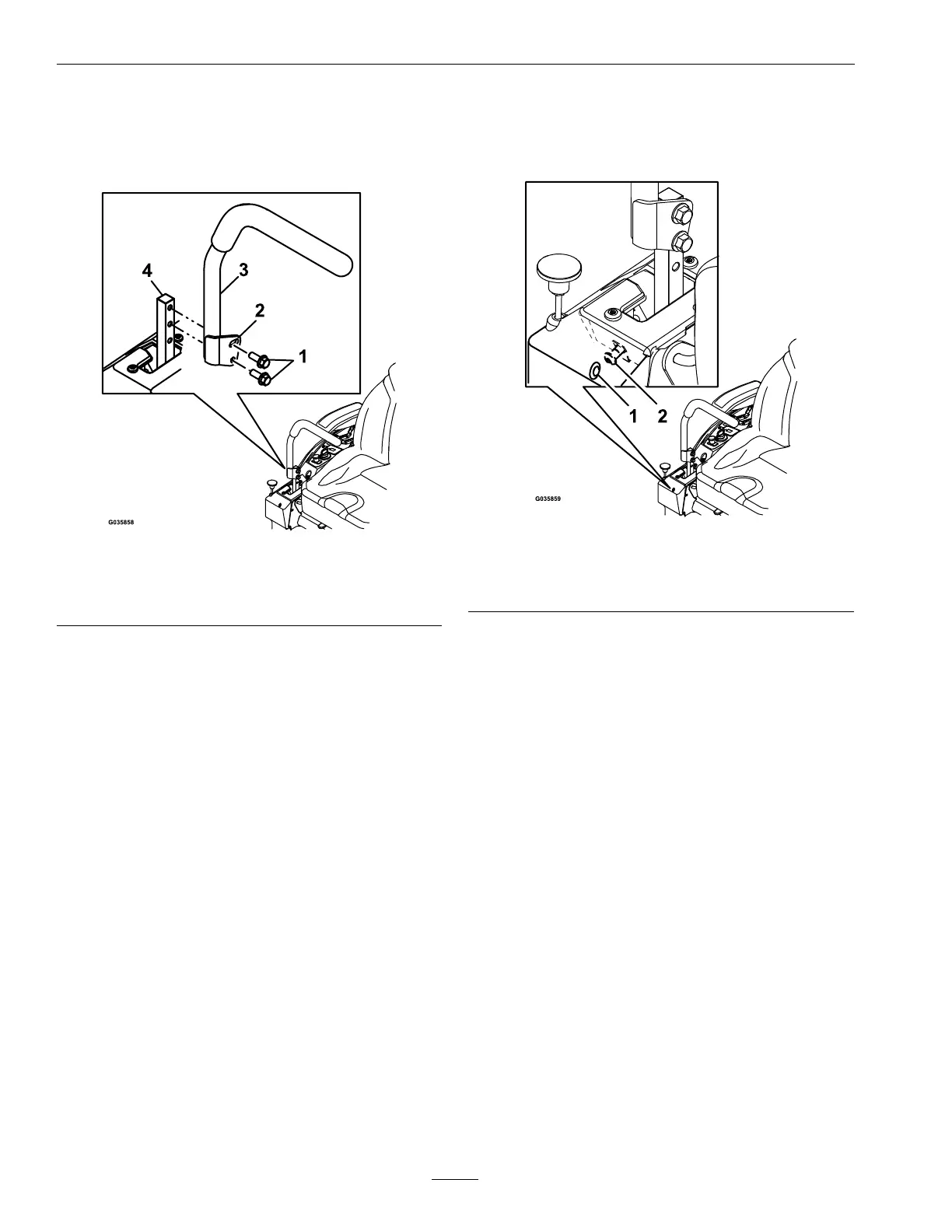

g035858

Figure74

1.Bolts

3.Controllever

2.Slottedhole4.Controlarmshaft

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththehardware.

3.Repeattheadjustmentfortheoppositecontrol

lever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollever

tothecontrolarmshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft.Tightenbothboltsto

securethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

FullForwardTracking

Adjustment

Ifthemachinetravelsorpullstooneside,whenthe

motioncontrolleversareinthefullforwardposition,

adjustthetrackingscrew .

1.Inserta3/16inchhexwrenchthroughtheaccess

holeonthefrontcoverpanel,rotatethetracking

screwclockwiseorcounterclockwisetoadjustthe

travelofthelever.

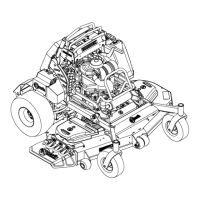

g035859

Figure75

1.Accessholeonfront

coverpanel

2.Trackingscrew

2.Drivethemachineandcheckthefullforward

tracking.

3.Repeatsteps1and2untildesiredtrackingis

obtained.

MotionControlLinkage

Adjustment

Locatedoneithersideofthemachine,belowtheseat

arethepumpcontrollinkages.Rotatingtheendnut

witha1/2inchdeepsocketwrenchallowsnetuning

adjustmentssothatthemachinedoesnotmovein

neutral.Anyadjustmentsshouldbemadeforneutral

positioningonly.

1.Priortostartingtheengine,pushthedecklift

pedalandremovetheheightofcutpin.Lower

decktotheground.

2.Raisetherearofmachineupandsupportwith

jackstands(orequivalentsupport)justhigh

enoughtoallowdrivewheelstoturnfreely.

3.Removetheelectricalconnectionfromtheseat

safetyswitch,locatedunderthebottomcushion

oftheseat.Theswitchisapartoftheseat

assembly.

70

Loading...

Loading...