Maintenance

2.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.Engageparkingbrake.

3.Placeasuitabledrainpanundertheoildrainand

removetheoildrainplug.

4.Aftertheoilhasdrained,replacetheplug.

5.Fillthecrankcasewithfreshoiltotheupperlimit

markonthedipstick.Useoilrecommendedin

theCheckEngineOilLevelsection.DoNot

overll

6.Wipeupanyspilledoil.

7.Connectthewiretothesparkplug.

8.Recycletheusedoilaccordingtolocalcodes.

CheckConditionOfBelts

ServiceInterval:Every25hours

1.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.Engageparkingbrake.

2.Removethebeltcoverfromtheleftsideofthe

unit.

3.Checkthebeltsforcracks,frayededges,burn

marksoranyotherdamage.

4.Replacethedamagedbelt.

5.Checkthehydrobelttensionasstatedinthe

Adjustmentssection.

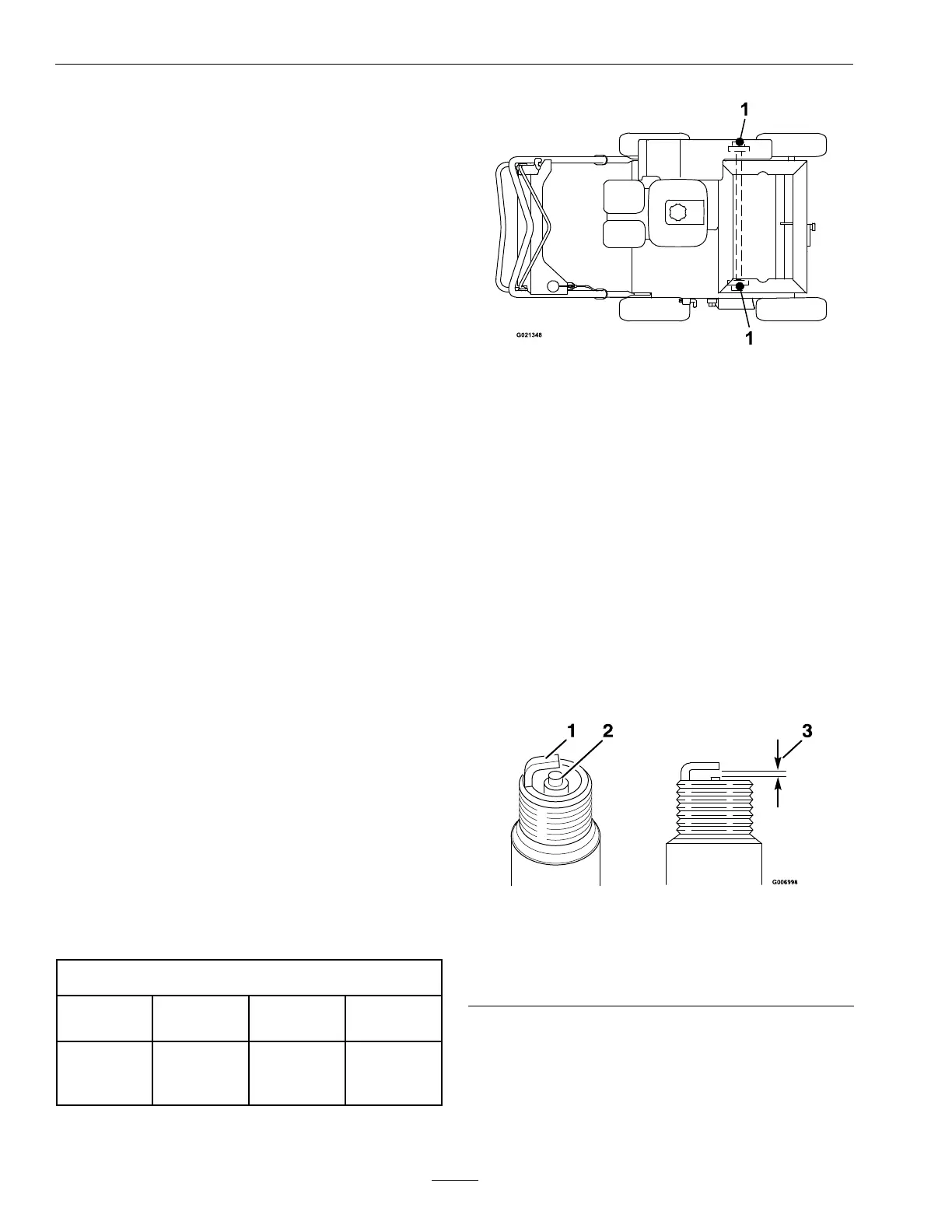

LubricateGreaseFittings

Note:Seechartforserviceintervals.

1.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.Engageparkingbrake.

2.Lubricatettingswithoneortwopumpsof

NGLIgrade#2multi-purposegungrease.

Refertothefollowingchartforttinglocations

andlubricationschedule.

LubricationChart

Fitting

Locations

Initial

Pumps

Numberof

Places

Service

Interval

1.Slicer

Shaft

Bearings

12

25hours

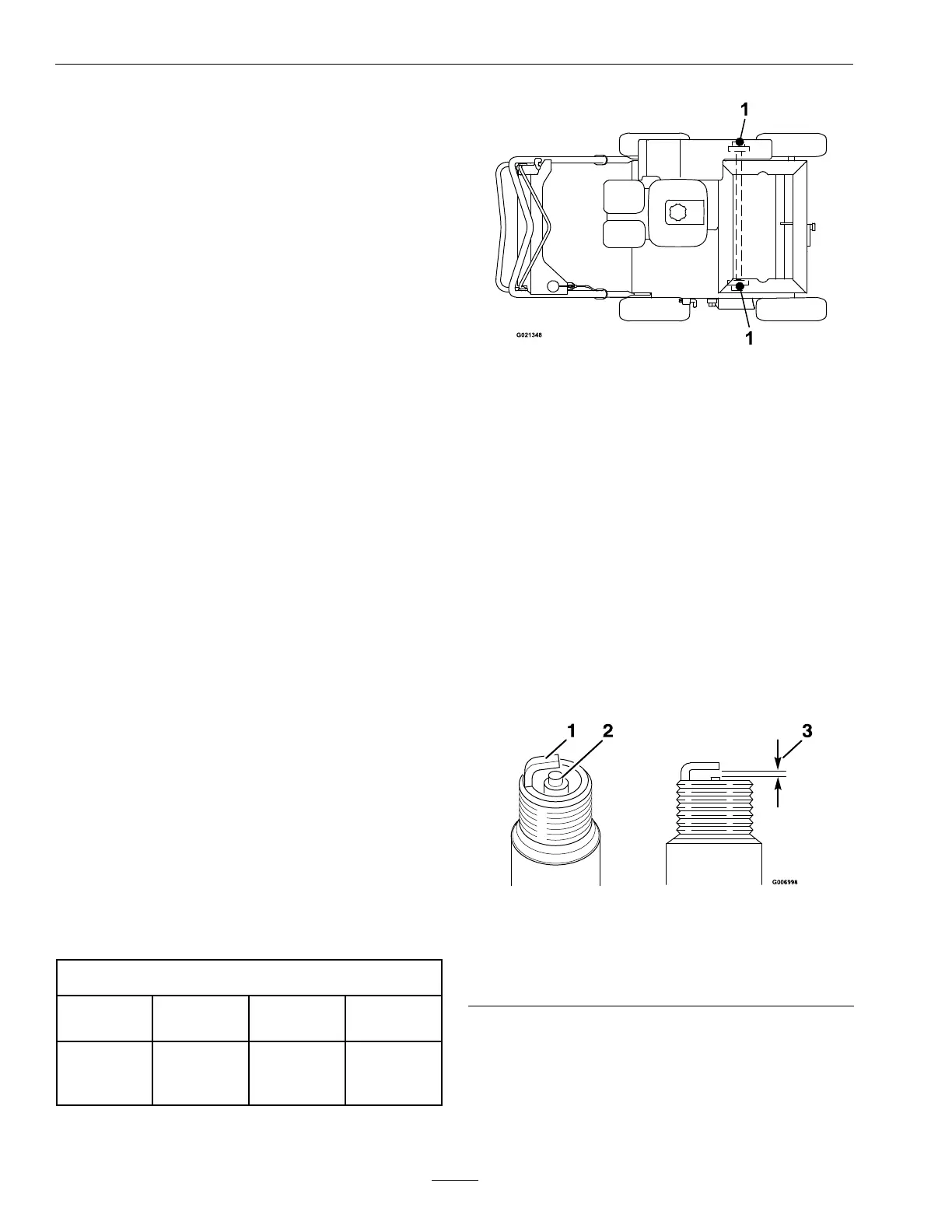

CheckSparkPlugs

ServiceInterval:Every100hours

1.Stoptheengineandwaitforallmovingpartsto

stop.Engageparkingbrake.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Note:Replaceacracked,fouled,ordirtyspark

plug.DoNotcleantheelectrodesbecausegrit

enteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.030inch(0.76mm)

(

Figure13).

Figure13

1.Sideelectrode

3.Airgap—0.030inch

(0.76mm)

2.Centerelectrode

insulator

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N-m).

8.Connectthewiretothesparkplug.

24

Loading...

Loading...