Maintenance

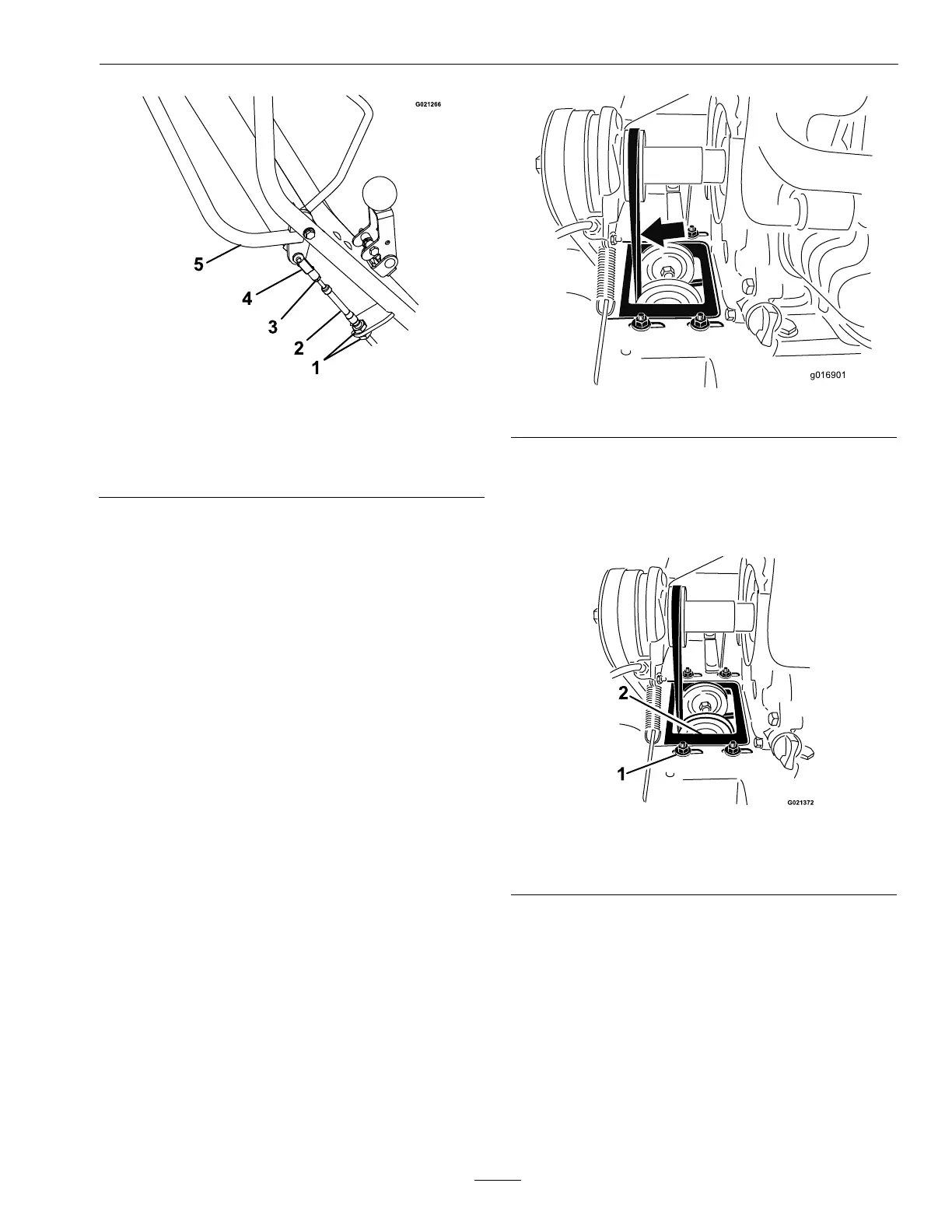

Figure14

1.Top/Bottomadjustment

nuts

4.Turnbuckle

2.Cable5.Self-propeldrivebail

3.Jamnut

•Ifthebaildoesnotcontactthehandle,then

proceedtostep4.

4.Removethehairpin,rotatetheturnbuckle

clockwiseonemorefullturn.

5.Reinstallthehairpinandrotatethejamnutagainst

theturnbuckle.

6.Starttheengineandtesttheadjustment,repeating

thisprocedureasnecessary.

AdjustingtheSelf-Propel

DriveBeltTension

Iftheself-propeldrivebeltsquealsduringoperation

(i.e.,whenmovedfromneutraltoforwardorreverse),

tightenthebeltasfollows:

1.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.

2.Raisethecuttingbladestothehighestposition.

3.Removeandretainthefourbolts,lockwashers,

andtwospacerssecuringthebeltcovertotheleft

sideofthemachineandremovethecover.

4.Checkthetensionofthetransmissiondrivebelt.

Itshouldnotexmorethana1/4inch(6mm)

withmoderatengerpressureappliedtothespan

justabovethemachineframe.

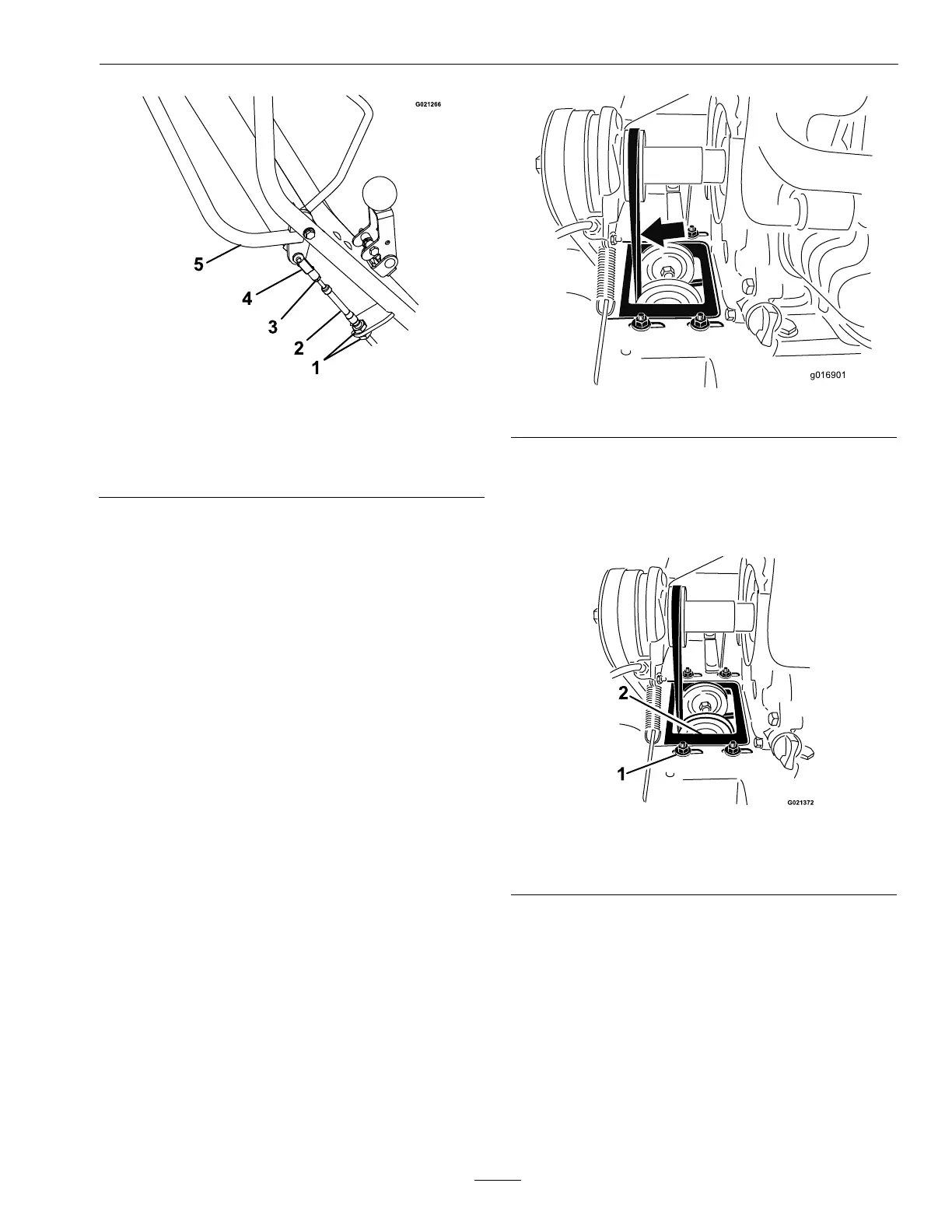

Figure15

5.Totightenthebelt,loosenthefourmounting

nuts/boltssecuringthepulleycarriagetothe

frameandmovethecarriagetotheleft,tightening

thebelt,thensecurethefourmountingnutsand

bolts.

Figure16

1.Nut

3.Machineframe

2.Pulleycarriage4.Bolt

6.Reinstallthebeltcoverusingthehardware

retainedinstep3.

AdjustingtheSeedGate

ClosedPosition

Iftheseedgateispartiallyopenwhentheseeder

controlleverisintheOffposition,completethe

following:

1.Stopengine,waitforallmovingpartstostop,and

removesparkplugwire.

27

Loading...

Loading...