DISPLAYS23.

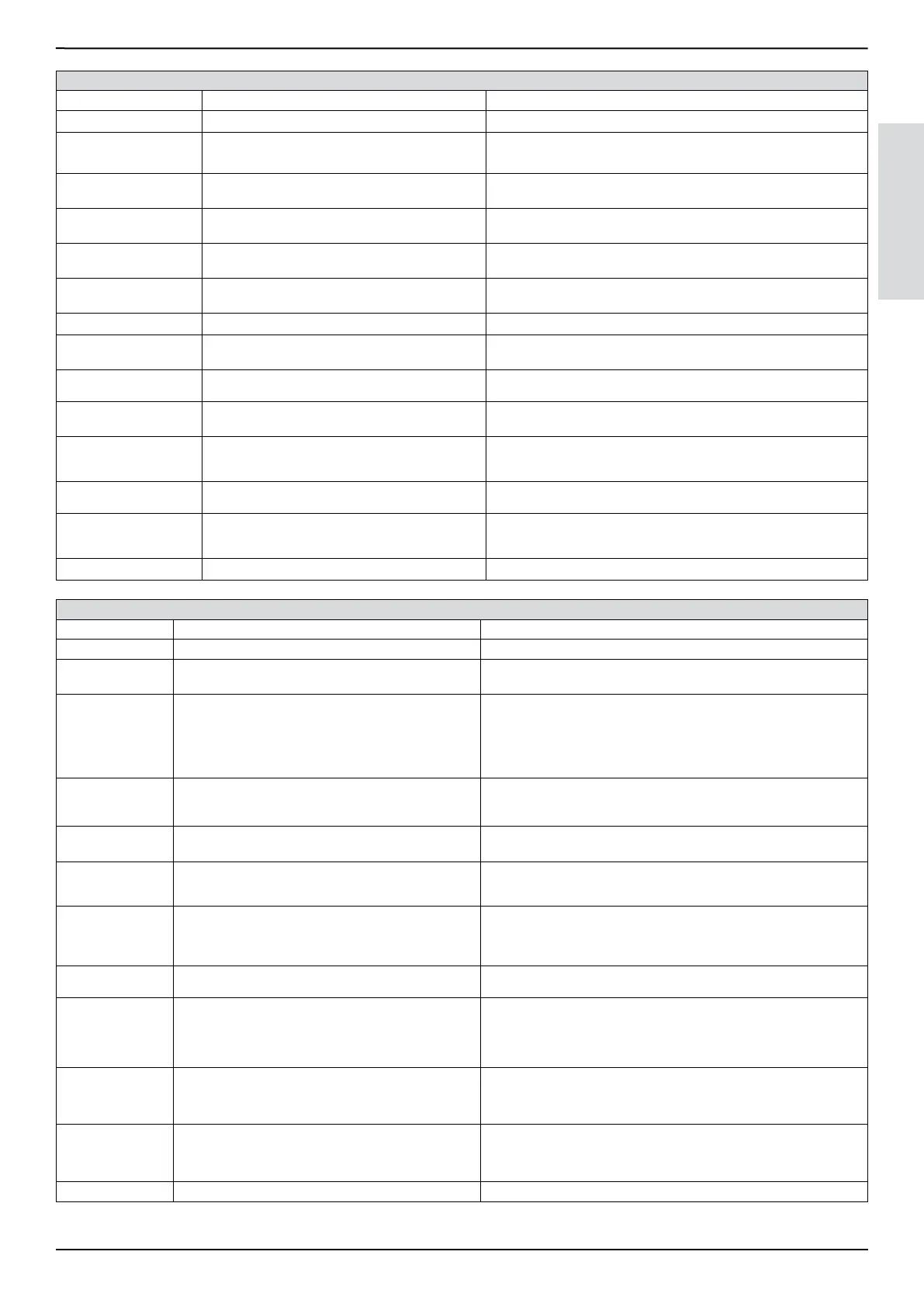

Display Reason Solution

START The start phase is in progress -

PELLET FEEDING

the continuous feeding of the pellets during the ignition

phase is in progress

-

IGNITION The boiler is in ignition phase -

STARTUP the work preparation phase is in progress -

WORK

the normal working phase is in progress, the boiler is

working at the power set

-

BURN POT CLEANING the automatic burn pot cleaning is in progress -

FINAL CLEANING the nal cleaning is in progress -

MODULATION the boiler is working at minimum power -

STANDBY

boiler waiting for re-ignition due to an external

thermostat

the boiler will only re-start when the external thermostats makes a request

COOL. STDBYBLACK OUT the boiler is cooling after a power cut. once cooling is completed it will automatically ignite

HOFF

boiler in stand-by for re-ignition because the

temperature of the water has exceeded the parameters

set

as soon as the water temperature drops below the pre-established

parameters, the boiler will switch back on

ANTIFREEZE

the anti-freeze function is in progress as the H2O t° is

below the factory set threshold

the pump is active until the water reaches the pre-set factory parameter

ANTILOCK

If the boiler has remained in the O status for at least 96

hours, the pump starts to function, so that blocking does

not occur.

the pump activates for a brief period, in a way to prevent blockage of the

same.

EXCH. BLOCK indicates the cleaning block of the exchanger contact after-sales centre

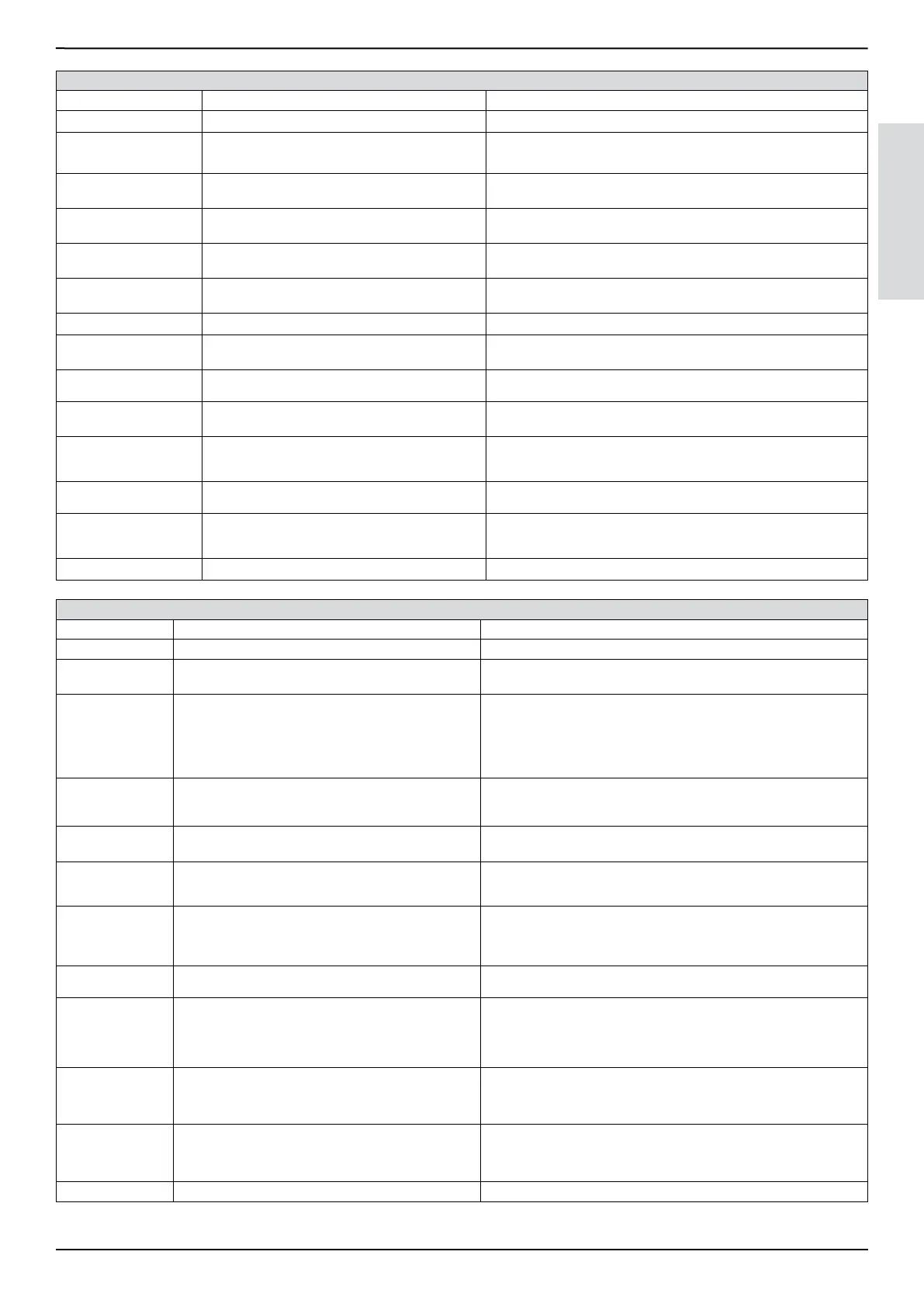

ALARMS24.

FUMES FAILURE Flue gas motor fault contact after-sales centre

FUMES PROBE Fumes probe failure. contact after-sales centre

HOT FUMES High ue gas temperature

check the calibration of pellet regulation. If this cannot be solved, contact an

authorised technician

NO FLOW ALARM

The door is not closed correctly.

The ash drawer is not closed correctly.

The combustion chamber is dirty.

The ue exhaust or air supply pipe is blocked.

Check hermetic door closure.

Check hermetic closure of the ash drawer.

Check cleanliness of the fumes pipe and the combustion chamber.

Check cleanliness if the air supply pipe and the ow sensor

NO IGNITION

The pellet feed-box is empty.

Pellet feed calibration inadequate.

Check for the presence of pellets in the feed-box.

Regulate the pellet ow

Check the procedures described in the “Ignition” chapter.

BLACKOUT NO IGN. No current during the ignition phase.

Take the boiler to OFF conditions using key 1 and repeat the procedure

described in the "Ignition" chapter.

NO PELLETS

The pellet feed-box is empty.

No pellet feed.

The motor reducer does not feed pellets.

Check for the presence of pellets in the feed-box.

Adjust pellet ow (see “Pellet feed adjustment”).

DEPR ALARM

The door is not closed correctly.

The ash drawer is not closed correctly.

The combustion chamber is dirty.

The ue exhaust pipe is blocked

Check hermetic door closure.

Check hermetic closure of the ash drawer.

Check cleanliness of the fumes pipe and the combustion chamber.

Check the mechanical pressure switch (air side)

DEPR SENSOR

DAMAGE

ow sensor faulty

sensor disconnected

contact after-sales centre

H2O OVERTEMP

the water in the boiler has exceeded 95°C.

Possible air in the system.

Insucient circulation.

No or inadequate safety zone.

Possible pump anomaly.

contact after-sales centre

MINIMUM

PRESSURE ALARM

the system pressure read by the pressure switch is too low.

Possible presence of air in the system.

Possible lack of water or leaks due to anomalies in some

system component.

contact after-sales centre

TRAPDOOR BLOCK The automatic cleaning of the burn pot results blocked.

Switch o the machine, wait for complete cooling and repeat the ignition

cycle.

If the problem persists, the reset operations must be carried out by an

authorised technician.

WATER PROBE H2O probe failure contact after-sales centre

Loading...

Loading...