3

A

B C

40 / 60

α°

X

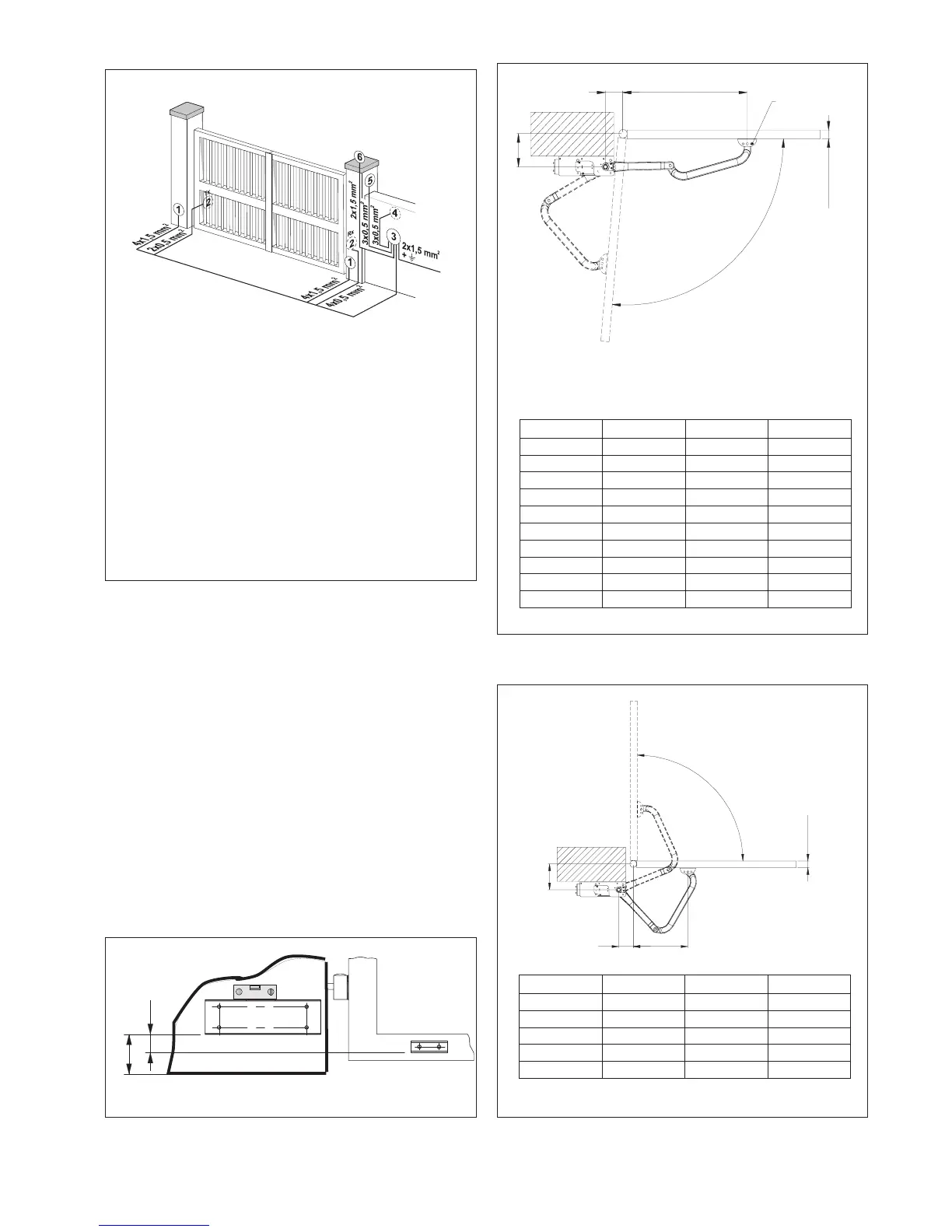

Fig. 3

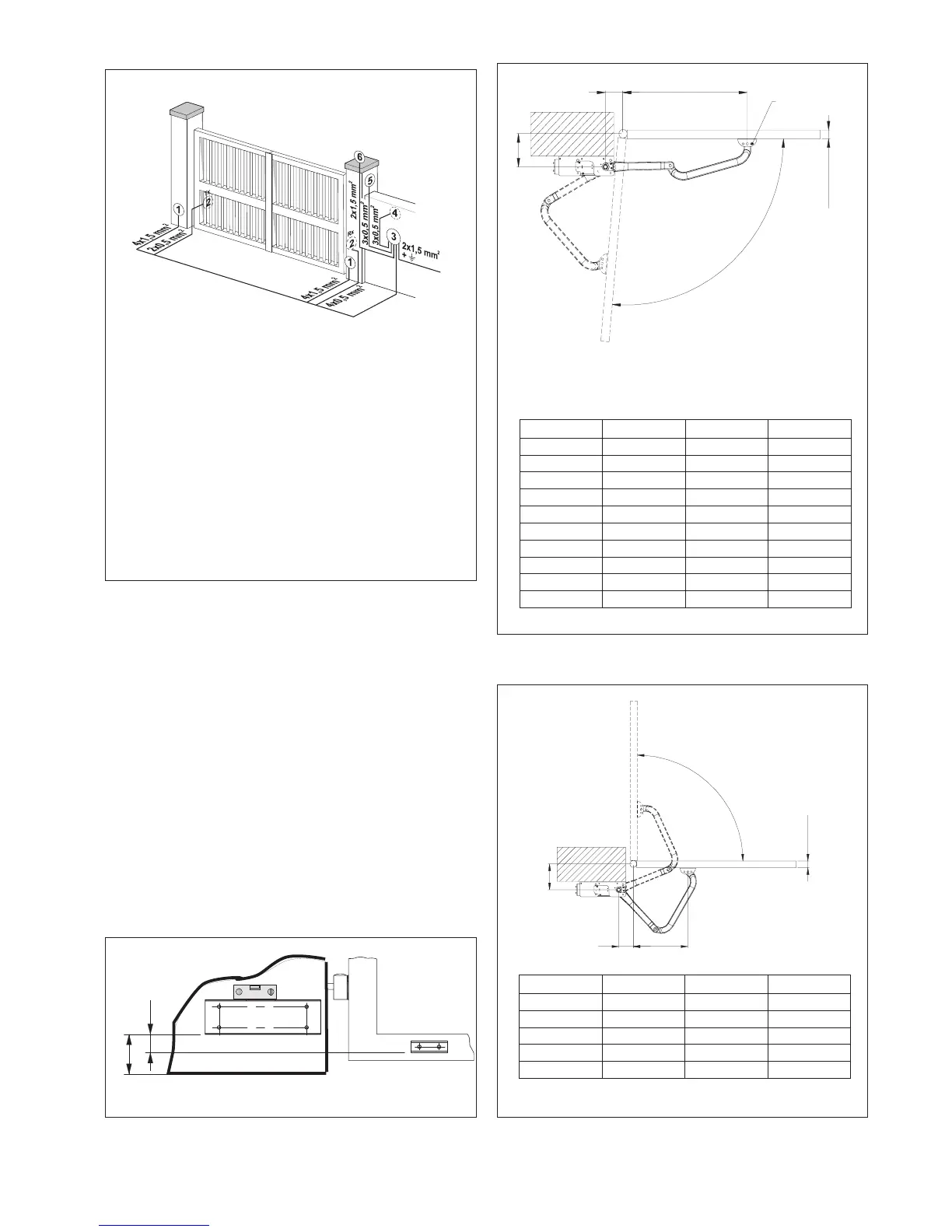

Fig. 6

Fig. 4

Fig. 5

3. ELECTRICAL EQUIPMENT (standards system)

4. INSTALLATION OF AUTOMATION

4.1. PRELIMINARY CHECKS

To ensure safety and an efficient automation, make sure the

following requirements are met:

• The gate structure must be suitable for automation. In

particular, make sure it is sufficiently sturdy and rigid, and

that its dimensions are in line with those indicated in the

technical specifications.

• Make sure that the leaves move properly and uniformly,

without any irregular friction during their entire travel.

• Check if hinges are in good condition.

• Make sure the travel limit mechanical stops are present.

• We advise you to carry out any metalwork jobs before

installing the automation.

4.2. INSTALLATION DIMENSIONS

Establish the installation position of the operator by consulting Fig.

4-5-6.

4.2.1. RECOMMENDED DIMENSIONS FOR INWARD OPENING

4.2.2. RECOMMENDED DIMENSIONS FOR OUTWARD OPENING

1) Operators mod. 390

2) Photocells

3) Electronic equipment

4) Key-operated push-button

5) Radio receiver

6) Flashlight

Notes: 1) To lay electrical cables, use adequate rigid and/

or flexible tubes.

2) Always separate low voltage accessories from

those operating at 230V~. To avoid any

interference, always use separate sheaths.

•measurements in mm

•measurements in mm

•measurements in mm

A B C (max)

60÷110 110÷130 730 90°

110÷160 110÷130 720 90°

160÷210 110÷130 710 90°

210÷260 110÷130 700 90°

260÷310 110÷130 690 90°

310÷360 110÷130 670 90°

60÷110 190÷210 650 120°

110÷160 230÷250 600 120°

160÷210 290÷310 540 120°

210÷260 310÷330 510 120°

αα

αα

α

A B C (max)

60÷110 110÷130 430 90°

110÷160 110÷130 380 90°

160÷210 110÷130 330 90°

210÷260 110÷130 280 90°

260÷310 110÷130 240 90°

αα

αα

α

CB

A

α

°

40 / 60

~ 200

~ 41

Notes: As for 120° openings the curved arm must be fixed

to the hole marked with the letter X

Loading...

Loading...