14

The outlet pipe must have:

• a diameter not less than that of the hood tting.

• a slight slope downwards (drop) in the horizontal sections to prevent conden-

sation from owing back into the motor.

• the minimum required number of bends.

• the minimum required length to avoid vibrations and reduce the suction per-

formance of the hood.

You are required to insulate the pipes if it passes through cold environments.

In the presence of motors with 500 CFM or higher, a check valve is present to

prevent external air owing back.

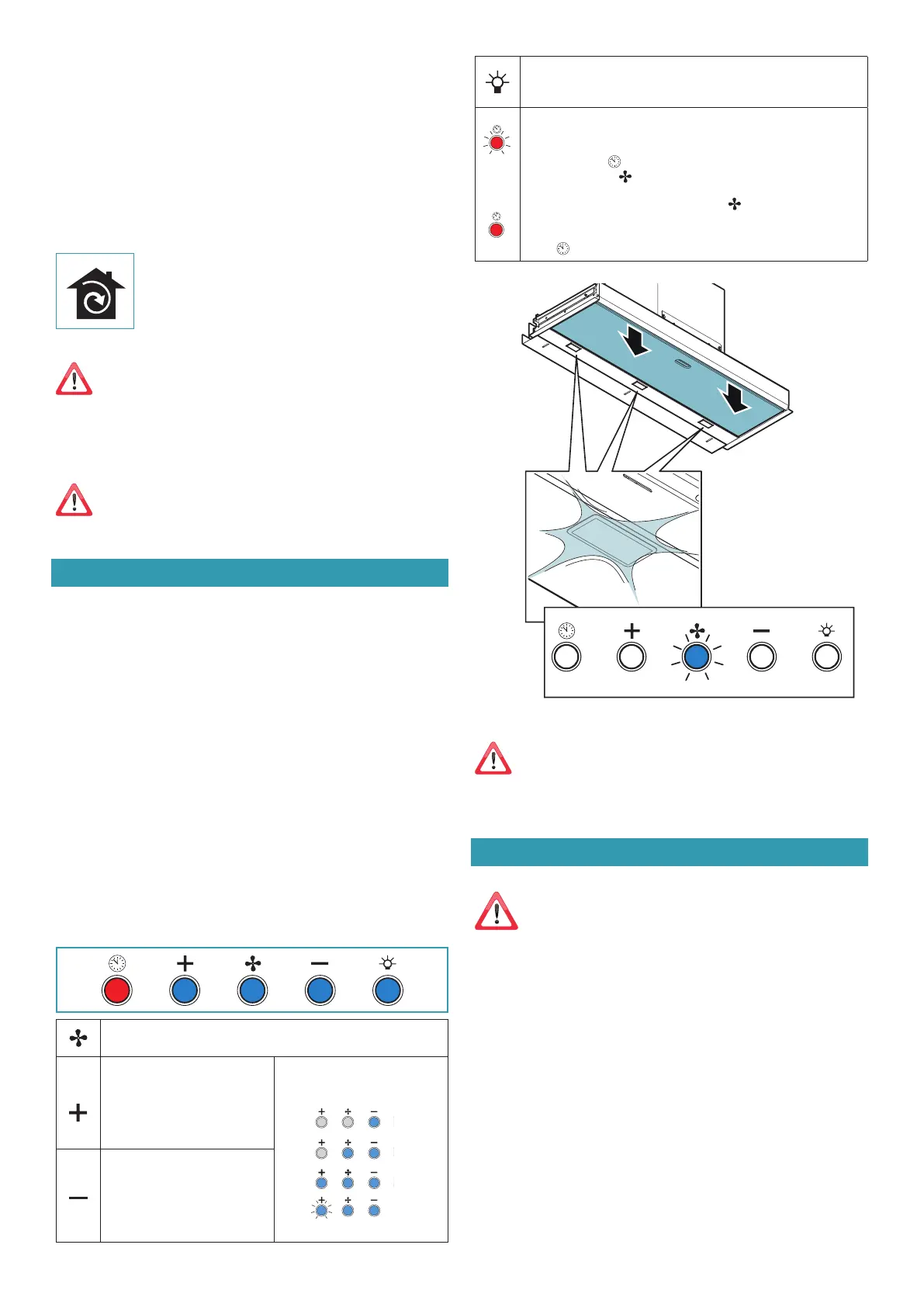

HOOD WITH INTERNAL RECIRCULATION FILTERING

In this model, the air passes through the charcoal lters to be

puried and recycled in the environment.

Ensure that the active carbon lters are assembled into the

hood, if not, install them as indicated in the assembly instruc-

tions.

In this version the check valve must not be assembled: remove it if it is

on the air outlet tting of the motor.

ASSEMBLY INSTRUCTIONS

only intended for personnel qualied

The hood can be installed in various congurations.

The generic assembly steps apply to all installations; for each case,

follow the specic steps provided for the required installation.

OPERATION

WHEN TO TURN ON THE HOOD?

Switch on the hood at least one minute before starting to cook to direct fumes

and vapours towards the suction surface.

After cooking, leave the hood operating until complete extraction of all vapours

and odours. By means of the Timer function, it is possible to set auto switch-o

function which will allow the hood to turn o automatically after 15 minutes of

operation.

WHICH SPEED IS TO BE SELECTED?

1st speed: maintains the circulation of clean air with low electricity consump-

tion.

2nd speed: normal conditions of use.

3rd speed: presence of strong odours and vapours.

4th speed: rapid disposal of odours and vapours.

WHEN SHOULD THE FILTERS BE WASHED OR REPLACED?

The metal lters must be cleaned every 30 hours of operation.

The active carbon lters must be replaced every 3-4 months, depending on the

use of the hood.

For further details see the “MAINTENANCE” chap.

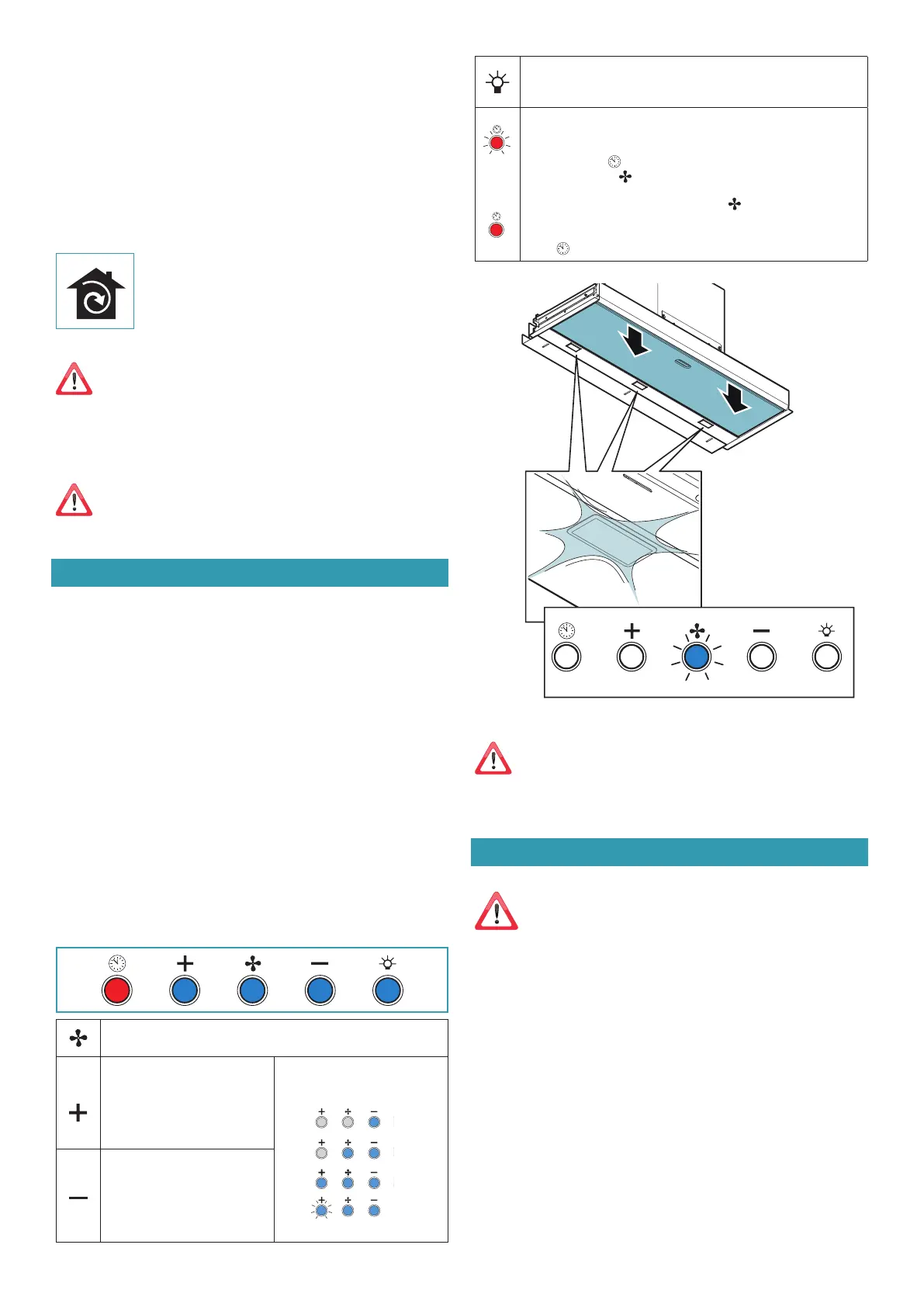

ELECTRONIC PUSHBUTTON PANEL

Motor ON/OFF

At start-up, the speed is 1.

Increase speed from 1 to 4

Speed 4 is only active for a few

minutes, then speed 3 activates.

The speeds are indicated by the

LEDs on the keys:

Speed 1

Speed 2

Speed 3

Speed 4

("+" LED ashing)

Reduce speed from 4 to 1

Light on/o

Short impulse: turn light on and o

Long impulse: change light tone from 2700K to 5600K

TIMER (red LED ashing)

Auto switch-o after 15 min.

The function deactivates (red LED o) if:

- The TIMER key ( ) is pressed again.

- The ON/OFF key ( ) is pressed.

FILTER ALARM (red LED steady on with ( ) o )

Anti-grease lter maintenance after approximately 30 hours of op-

eration.

Press ( ) the meter for 3 seconds to reset.

If the pushbutton panel is completely inactive, before contacting

the Technical assistance service, disconnect power temporarily to

the appliance (about 5“), possibly by acting on the main switch, to

restore normal operation.

If this measure has no eect, contact the Technical assistance service.

MAINTENANCE

Before cleaning or carrying out maintenance operations, discon-

nect the equipment by removing the plug or switching o the

main switch.

Do not use detergents containing abrasive, acidic or corrosive substances

or abrasive cloths.

Regular maintenance guarantees proper operation and performance over time.

Special attention is to be paid to the metal anti-grease lters : frequent clean-

ing of the lters and their supports ensures that no ammable grease is accu-

mulated.

CLEANING OF EXTERNAL SURFACES

You are advised to clean the external surfaces of the hood at least once every

15 days to prevent oily substances and grease from sticking to them. To clean

the brushed stainless steel hood, the Manufacturer recommends using "Magic

Steel" wipes.

Alternatively and for all the other types of surfaces, it can be cleaned using a

damp cloth, slightly moistened with mild, liquid detergent or denatured alcohol.

Complete cleaning by rinsing well and drying with soft cloths.

Loading...

Loading...