c XII

MAINTENANCE

INSTRUCTIONS

F 240

33

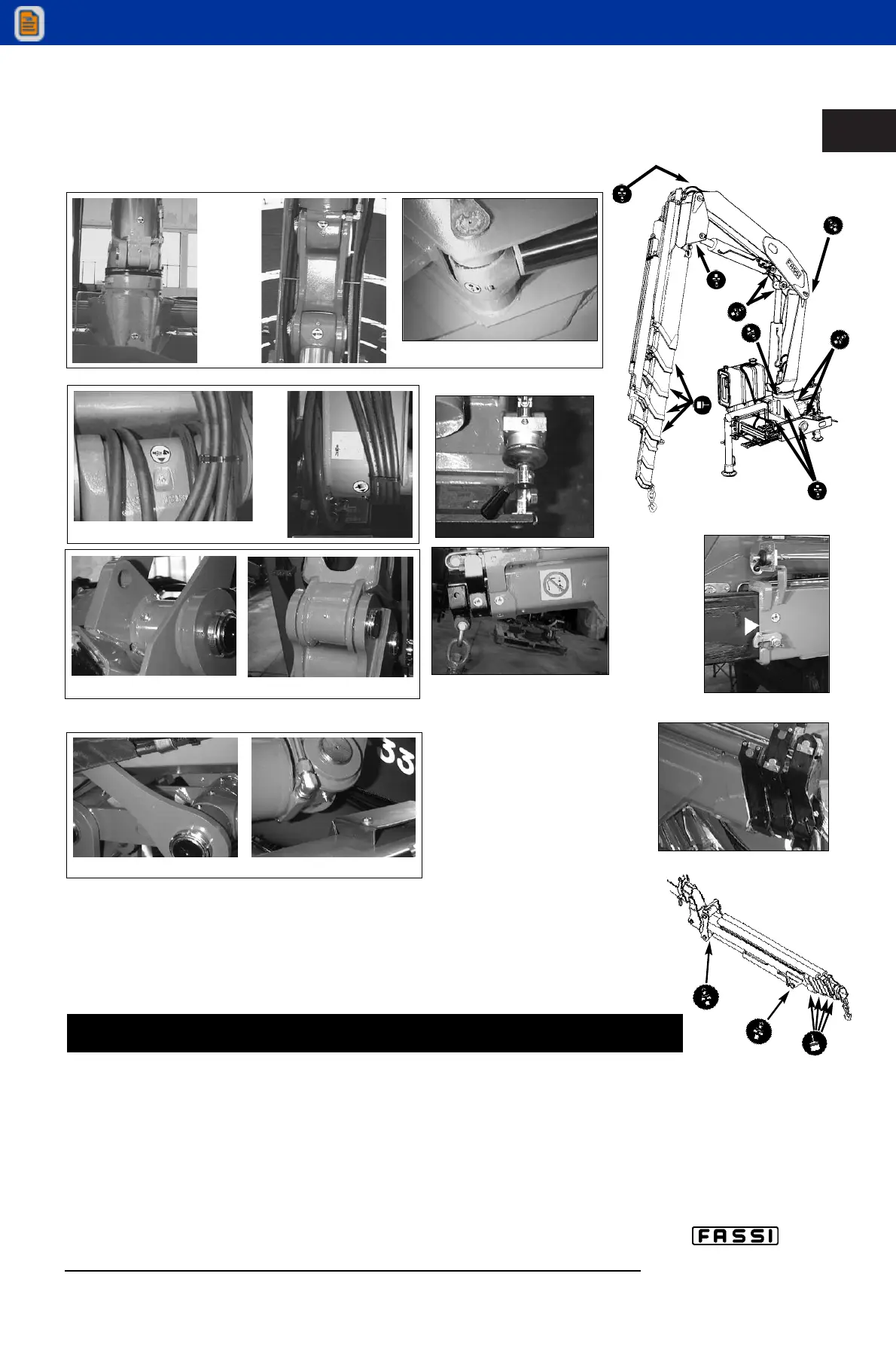

- Fig. 45-45a-45b show the lubricators of the inner and outer rams.

- Fig. 46-46a show the lubricators of the pin articulation column - inner boom

and inner boom - outer boom.

- Fig. 47 shows the lubricator of the multifunction return deviator.

When the hydraulic jib is fitted

- Fig. 48-48a

show the lubri-

cators of the articulation

pins for connecting boom

- jib outer boom and fork.

- Fig. 48b-48c

show the

lubricators of the jib outer

boom and of the fork.

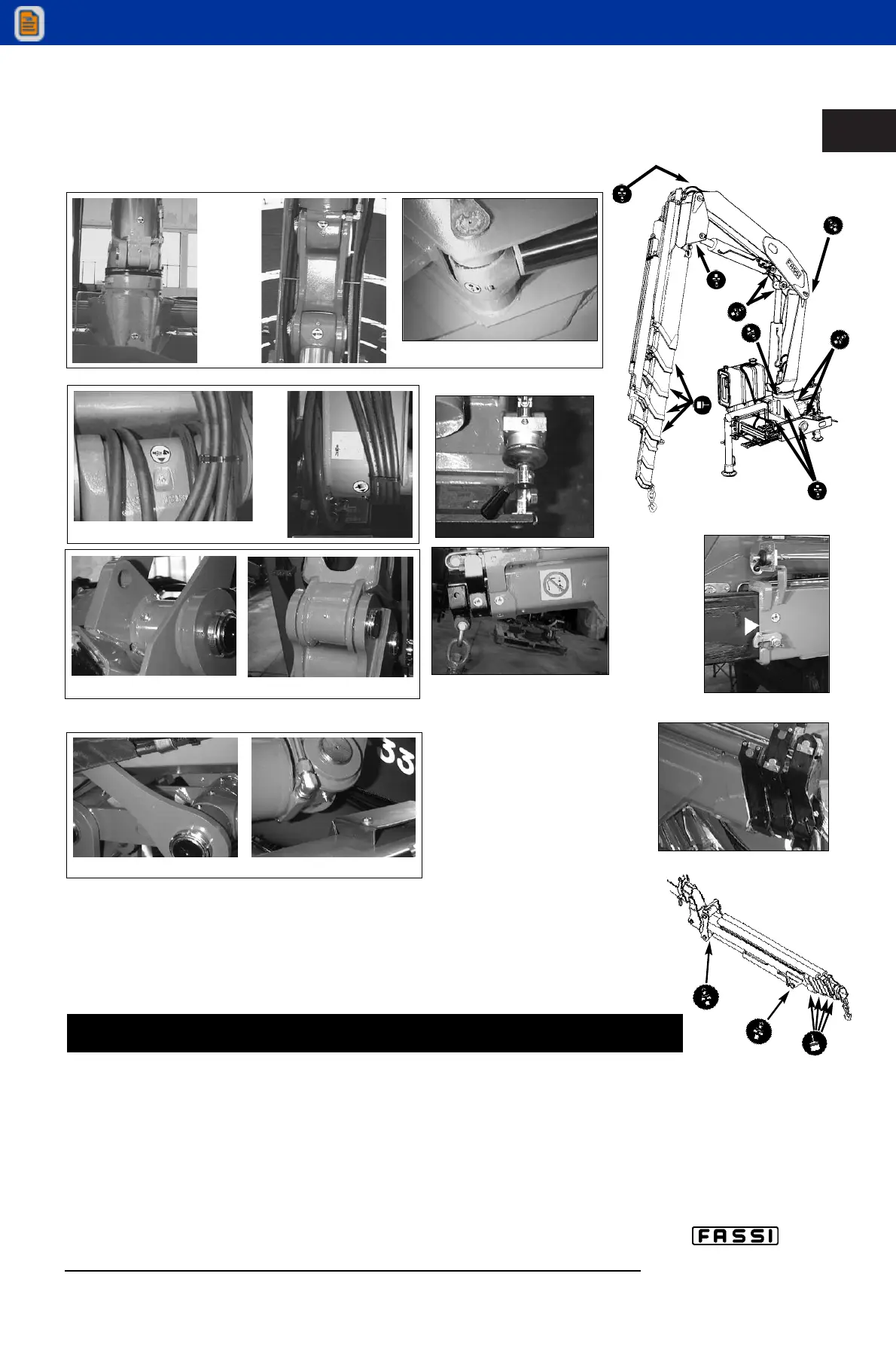

For the sliding sections of

the extension booms of the

crane (fig. 49) and of the hydraulic jib (fig. 49b) and of the outrigger supports

(fig. 49a) guide shoes made from a special material have been fitted: to ease

their movement it is recommended to smear a light film of grease on them,

taking care that the surfaces of the extension booms are free from impurities

such as sand etc.

Use a grease with the same characteristics indicated in the table on page

37.

Check the tightening torque of the tie rods fixing the crane to the vehicle frame.

Check the tightening torque of the securing bolts for the ram pins.

Check the guide shoe wear as it affects the sliding section tolerances; if the

clearances are considerable, damage to the rams and the structure may

occur.

Replace the oil filter cartridges.

Clean the air filter placed in the top of the oil tank filter cap.

Completely replace the hydraulic oil.

(!) The waste oil must be disposed of by authorized persons.

fig. 49

fig. 49a

fig. 49b

fig. 45a

fig. 45

fig. 45b

fig. 40

fig. 46a

fig. 46

fig. 48a

fig. 48

fig. 48c

fig. 48b

fig. 47

fig. 41a

After every 500 working hours

Loading...

Loading...