MSD

TM

Series

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 18 -

Pump Assembly Continued

Figure 24 - Install Flex Coupling On Motor

Shaft

APPLY SYSTEM COMPLIANT

ANTI-SEIZE COMPOUND

Flexible Coupling Check

6. Apply a system compliant anti-seize com-

pound to the motor shaft keyway and install

the motor shaft key and coupling.

NOTES: If the motor shaft key does not t

properly in the coupling keyway, lightly le the

motor shaft key until a proper t is obtained.

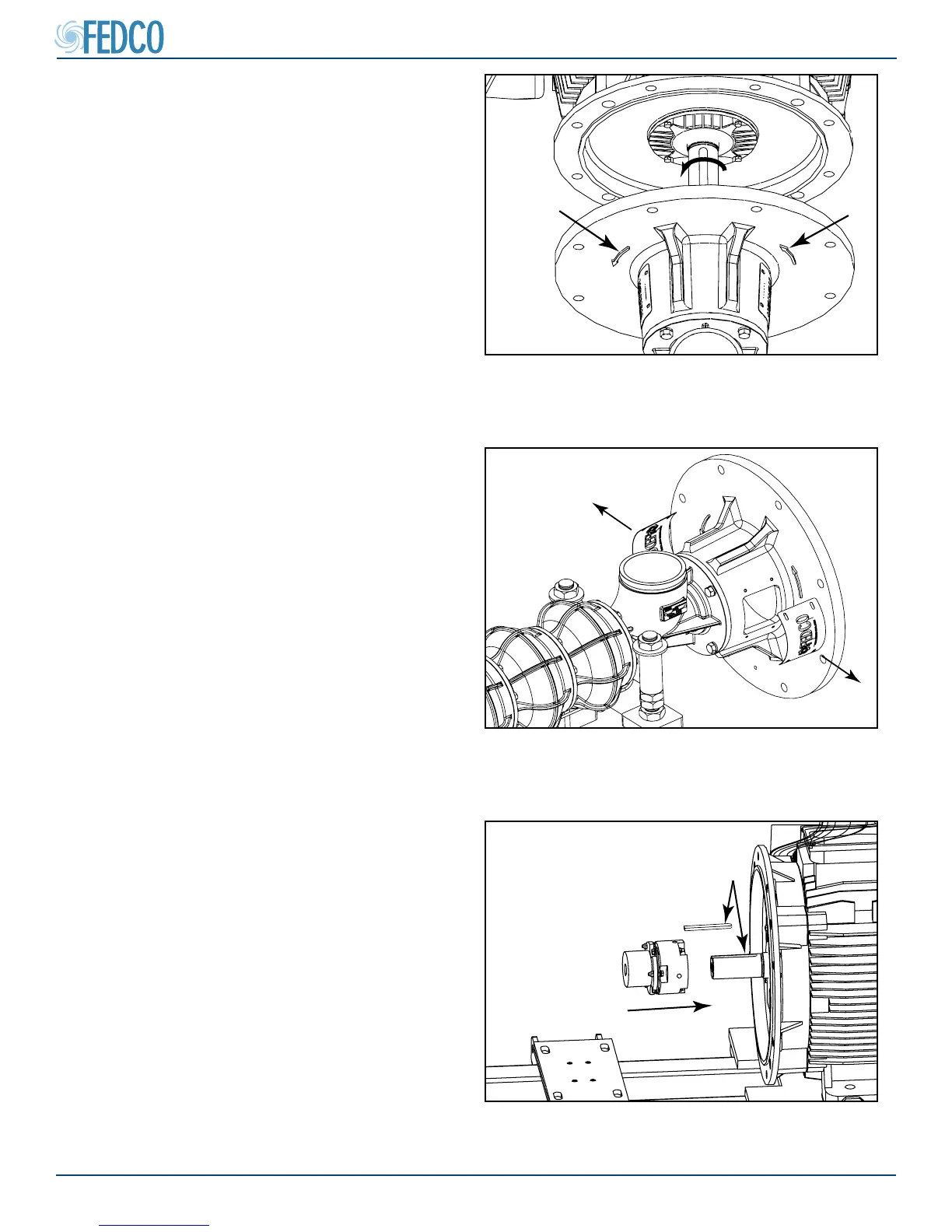

Figure 23 - Coupling Guard Removal

5. Loosen screws and remove the two coupling

guards. This allows better access to view

the coupling alignment in later steps.

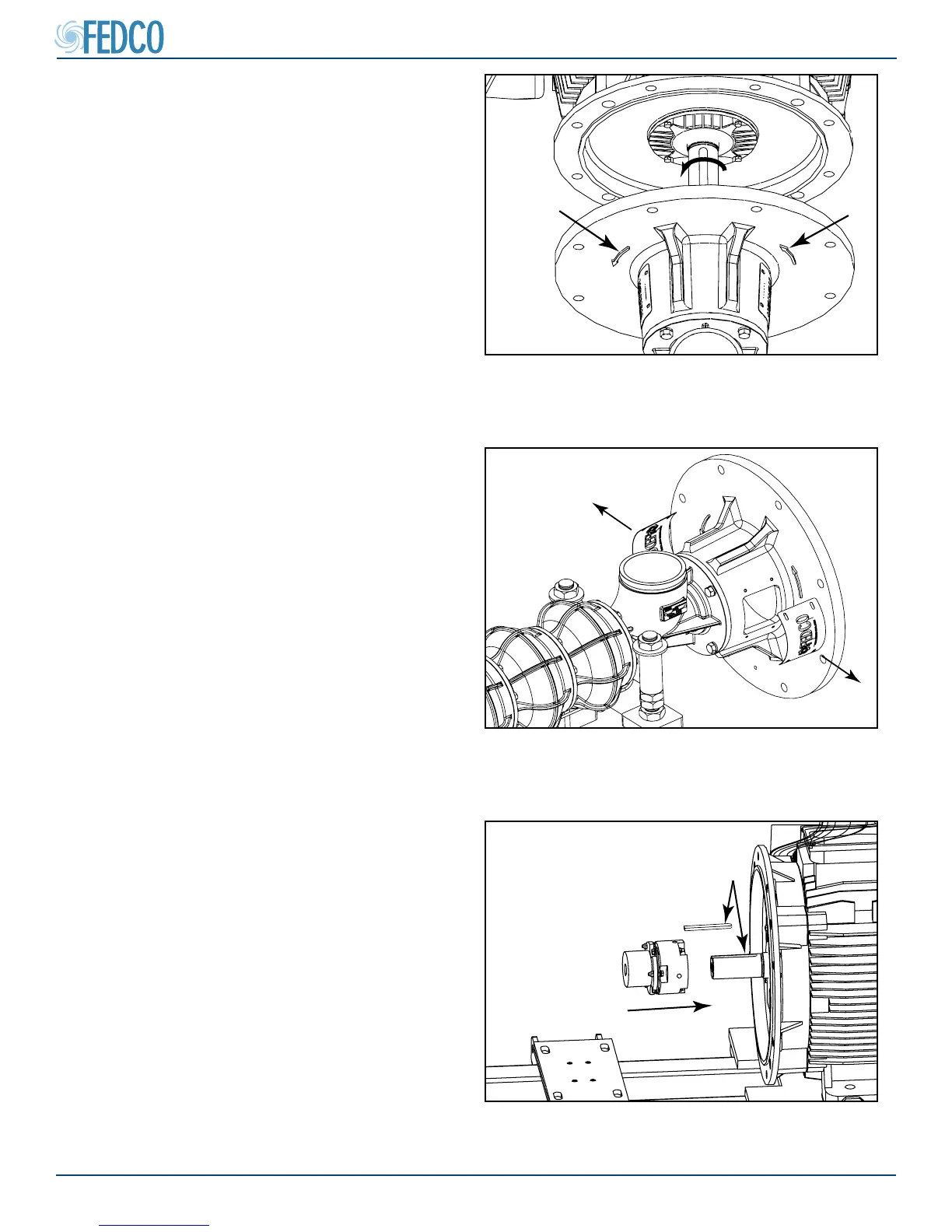

Figure 22 - Direction Arrows On Motor Adapter

3. Prior to pump installation energize the motor

to determine the direction of motor rotation.

The correct rotation is indicated by arrows

on the motor adapter. If the rotation is incor-

rect, reverse the polarity of motor wiring to

change the direction of rotation.

NOTES: Reversing polarity of the VFD power

input wires will not change the motor rotational

direction.

4. If the motor rotational direction is correct,

disconnect power to the motor according to

lock-out/tag-out procedures and complete

all electrical connections according to local

codes and regulations.

Loading...

Loading...