MSD

TM

Series

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 47 -

Pump Assembly Continued

Pump Piping Connections

Minimizing Excessive Loads/ Pipe Stress

• Do not use the pump as an anchorage point

for the piping.

• Anchor the pipelines in close proximity

to the pump and connect them without

transmitting any stresses or strains.

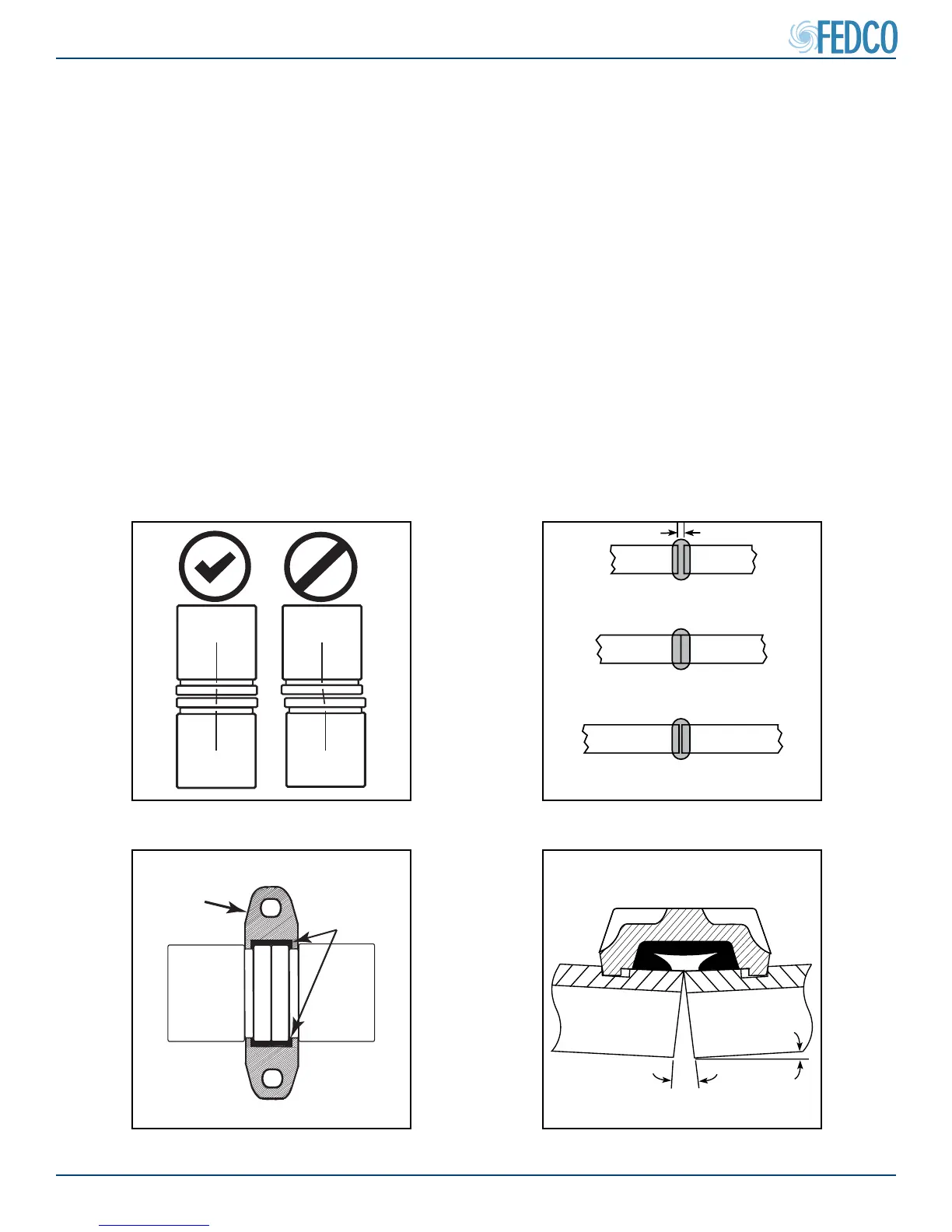

Piping Alignment

• Accurate alignment and support of all piping

connected to the pump is critical.

• Any movement occurring at the inlet

or discharge connections may cause

misalignment and stress over time.

• Do not force any misaligned pipes to

connect to the pump discharge or inlet.

Pipe Coupling Connections

• Follow all manufacturer installation and

torque specications.

• Align all piping carefully before installing

couplings.

• Make sure all seals seat correctly inside

the coupling. If piping or seals are not

aligned correctly, leaking may occur under

pressure.

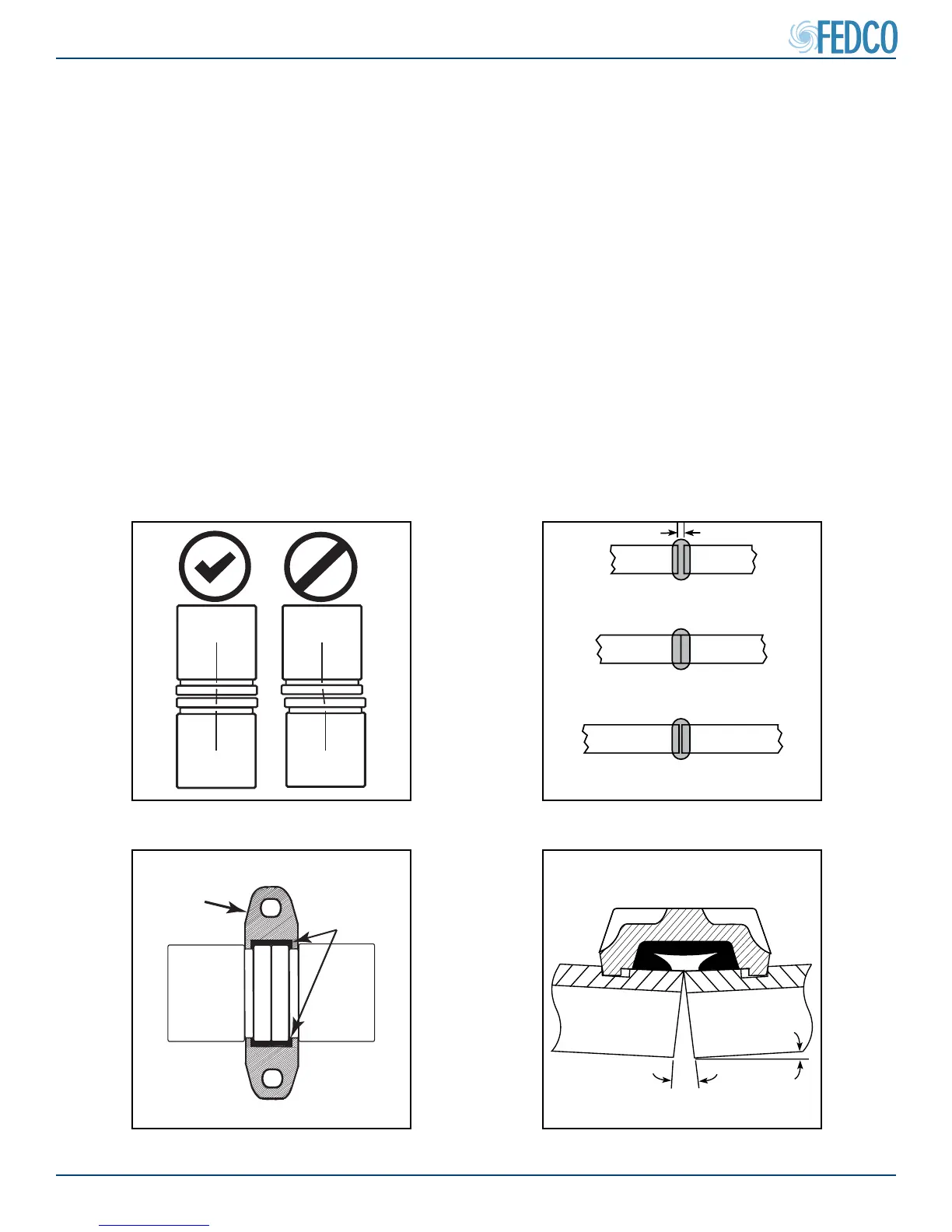

• Provide for expansion or contraction

of piping. Always consider best setting

for pipe end gaps for handling angular

deection and combinations of expansion

and contraction. Separation and deection

recommendations are specied on the

following page.

YES

NO

Figure 89 - Proper Piping Alignment

GROOVED

COUPLING

COUPLING

SEAL

Figure 90 - Typical Grooved Coupling

FULLY APART

Expansion Only

PARTIALLY GAPPED

Expansion and Contraction

FULLY BUTTED

Contraction Only

Figure 91 - Pipe End Separation

Θ

Θ

Figure 92 - Angular Deections

Loading...

Loading...